Product Details

Our vacuum transformer oil purification equipment can effectively remove moisture, gas, solid impurity from old or new transformer oil, to improve the flash point and dielectric strength value of insulation oil. AOP can increase the dielectric insulation value more than 35KV at one time. It suits for purifying all kinds of insulation oil, especially suits for purifying transformer oil from 110KV and above 110KV UHV power transmission and distribution projects; also suits purifying of capacitor oil, mutual inductor oil, switch oil, cable oil.

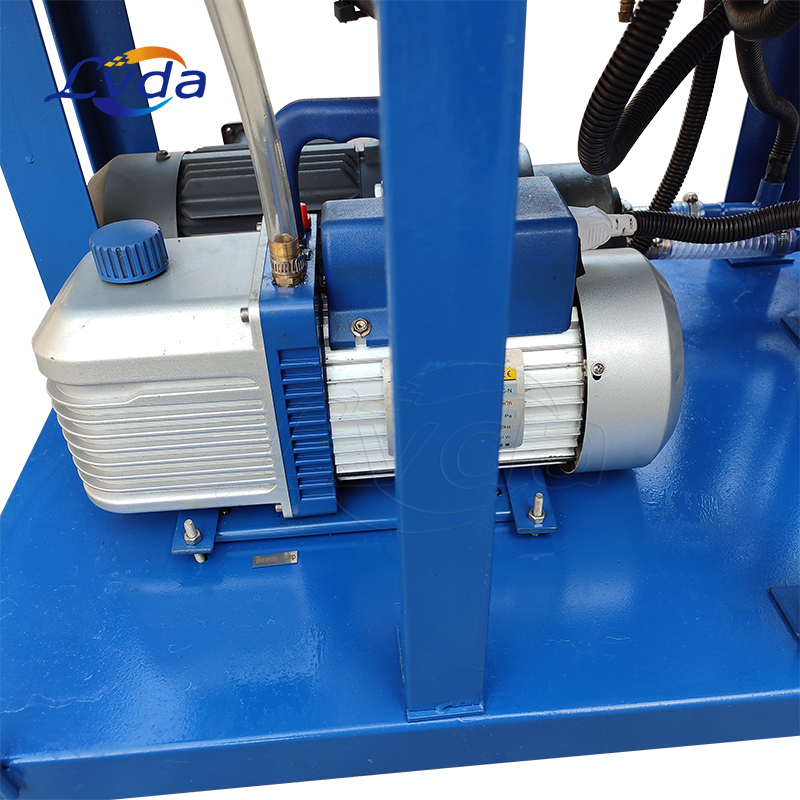

Our vacuum transformer oil purification equipment adopts “T” type vacuum evaporation tank, it separates the evaporation tank and the oil tank, improving evaporation efficiency, prolong the machine lifetime.

Its working Principle

Water dissolves in transformer oil until the oil internal pressure is balanced . If the pressure, temperature, and saturation which associated with the balance pressure are broken, transformer oil either overflows or absorbs moisture until get to a new balance under new conditions. For our vacuum transformer oil purification equipment, the working vacuum is less than 133pa, it can atomize oil into less than 50um, so it can quickly reduces moisture content to less than 3ppm.

Product parameters

Model

| AOP-1V-25

| AOP-1V-32

| AOP-1V-50

| AOP-1V-100

| AOP-1V-150

| AOP-1V-200

|

Flow rate(L/min)

| 25

| 32

| 50

| 100

| 150

| 200

|

Working pressure(Mpa)

|

|

| 0.6

|

|

|

|

Rated vacuum(Mpa)

|

|

| ≤ - 0.095

|

|

|

|

Water content

|

|

| 5 - 30

|

|

|

|

Air content

|

|

| ≤0.2% |

|

|

|

Coarse filtration(μm)

|

|

| 100 |

|

|

|

Grade 1 filter rating(μm)

|

|

| 10、20 |

|

|

|

Grade 2 filter rating(μm)

|

|

| 3/5 |

|

|

|

Pressure differentials

|

|

| 00.2Mpa |

|

|

|

Voltage(V)

|

|

| AC 380V(Three-phase)、50Hz |

|

|

|

Motor power(kw)

| 18 | 26 | 36 | 65 | 65 | 135 |

Weight(kg)

| 360

| 470

| 680

| 840

| 960

| 1500

|

Dimensions(mm) | 12500x920x1600

| 1350x980x1600

| 1500x1060x1800

| 1600x1080x2100

| 1800x1200x2200

| 2000x1200x2200

|

Note: * -is filter's rating,such as 03 is 3 microns.

**-is the suitable medium, Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate

hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

****-explosion-proof type: add F before type, Omission: normal type

Product features

“T ”type double vacuum separation technology, double stages thin film drying degassing technology, double evaporation area and degassing time.

A special degassing tank: anti-foam structure & dual electronic foam monitoring system “( key components are from Switzerland), completely eradicating oil entering into vacuum pump.

Control System: Optimized design of control interlock protection device, overpressure alarm and protection, phase sequence protection, to ensure whole machine working stably for a long time. Automatic pressure alarm system, automatic overload protection system, automatic constant temperature system, automatic bubble elimination system, automatic protection of blowout prevention and other advanced technologies, to ensure the safe operation of untended operation.

Oil atomized particles size is less than 50um, largely increasing efficiency for water molecules and gas molecules escaping from oil molecules.

Vigorously increase contact area between heater and oil (2w/cm2), reduce the surface temperature of heater, and prevent oil cracking and aging.

To install liquid level and temperature protector of heater, prevent instantaneous high temperature of heater.

Vacuum pump cooler preposition, to reduce water get into vacuum pump, reduce the frequency to change vacuum pump oil and extend vacuum pump lifetime.

High precision filtering element, fine accuracy is 1 micron(optional: 0.5 micron),β≥1000.

Outlet oil pressure protector, to monitor pressure of oil filters all the time, effectively protecting machine and operators.

Adopt interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak.

Adopt the high pressure oil pump, oil transmission stable, low noise, long life

Using famous brand high quality components, performance is stable and reliable.

Automatic float ball & electronic oil level automatic controlling system, to realize automatic bubble elimination, unattended operation.

Easy operation and trouble reminder and trouble shooting tips.

Product applications

Filtering hydraulic systems

Filtering steam turbine lube systems

Almost any industrial equipment containing oil

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português