Product Details

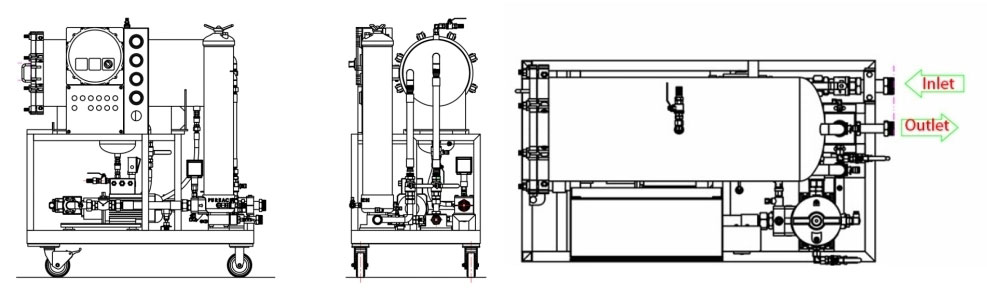

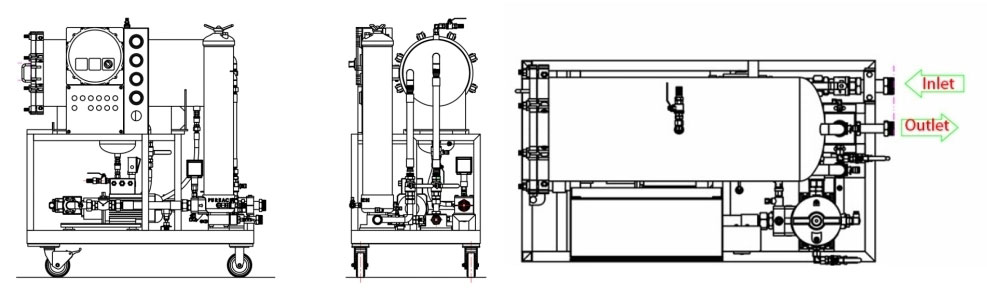

Our cutting-edge transformer oil filtration and purification systems are meticulously engineered to systematically degas, dehydrate, and filter, expeditiously revitalizing the dielectric strength of transformer oil and insulating oils.

Offering versatility to meet diverse needs, our systems are available in a range of configurations, catering to process flow rates from 3 gallons per minute (GPM) to an impressive 100 GPM. This flexibility ensures that our solutions can seamlessly integrate into various industrial setups, providing efficient and tailored performance.

Driven by a commitment to addressing specific applications, we extend beyond conventional approaches by offering both vacuum purification and absorptive media solutions. This dual approach allows us to cater to a spectrum of requirements, ensuring that our systems are adaptable and effective in meeting the unique challenges posed by different applications.

For a personalized consultation on your specific needs, we encourage you to reach out to us directly. Our team is dedicated to understanding the intricacies of your applications, allowing us to provide tailored recommendations and assistance in sizing the optimal system for your unique requirements. Your satisfaction and the effectiveness of our systems in meeting your needs are our top priorities. Contact us today, and let's embark on a journey to enhance the efficiency and longevity of your transformer and insulating oils.

Optimized Specifications:

Water Removal: Achieves a remarkable reduction from 100 ppm to < 5 ppm

using the ASTM method D1533.

Total Gas Content: Successfully lowers from 12% to < 0.25% by volume with

precision, adhering to the ASTM method D2945.

Particulate Removal: Filters out an impressive 99% of particulates with a

size ≥ 0.5 microns.

Dielectric Strength: Restores oil dielectric strength to the manufacturer's

original specifications, validated by the ASTM method D1816.

Enhanced Features:

Unique Multi-Level Vacuum Chamber Design: Exclusive to Vacudyne, optimizing

the efficiency of the vacuum process.

Automated Control System: Ensures ease of use and allows for unattended

operation, enhancing operational convenience.

Intuitive Display: Presents real-time information on vacuum, pressure,

temperature, and filter conditions for enhanced monitoring.

Accessible Operating Parameters: Easy access to all critical operating

parameters for seamless adjustments and maintenance.

Built-in Logging Buffer: Facilitates historical information retrieval for

comprehensive system analysis.

Electronic Flow Meter: Equipped with a lifetime display and user-resettable

features for accurate flow monitoring.

VFD Pump Drives: Incorporates Variable Frequency Drive pump drives for

efficient and adaptable performance.

Oil Level Control: Includes high and low oil level safety shutdown for

enhanced safety measures.

Multi-Stage Foam Control: Optimizes processing with a multi-stage system for

effective foam control.

TEFC Motors: Ensures high efficiency with Totally Enclosed Fan-Cooled

motors.

Single Mechanical Seal Oil Pump: Reliable and efficient oil pump design with

a single mechanical seal.

Low Watt Density Heaters: Facilitates water removal with low watt density

heaters.

NEMA 12 Control and Power Cabinets: Ensures compliance with industry

standards for control and power systems.

Inlet and Outlet Filters: Includes filters for effective particulate removal

at both the inlet and outlet points.

Booster/Backer Vacuum Pump: Ensures a consistently deep vacuum for optimal

performance.

Thermostatically Controlled Heater: Offers selectable capacity for precise

temperature control.

Heavy-Duty Rigid Steel Construction: Provides long-lasting durability with

robust steel construction.

Oil Retentive Skid Design: Designed for spill containment, enhancing safety

measures.

Versatile Applications:

Transformer Insulating Oil

Switchgear Insulating Oil

Load Tap Changer Insulating Oil

Other Liquid Applications: Suitable for various liquids requiring impurity

removal and restoration.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português