Product Details

Vacuum Dehydrator Oil Purification System

The working principle

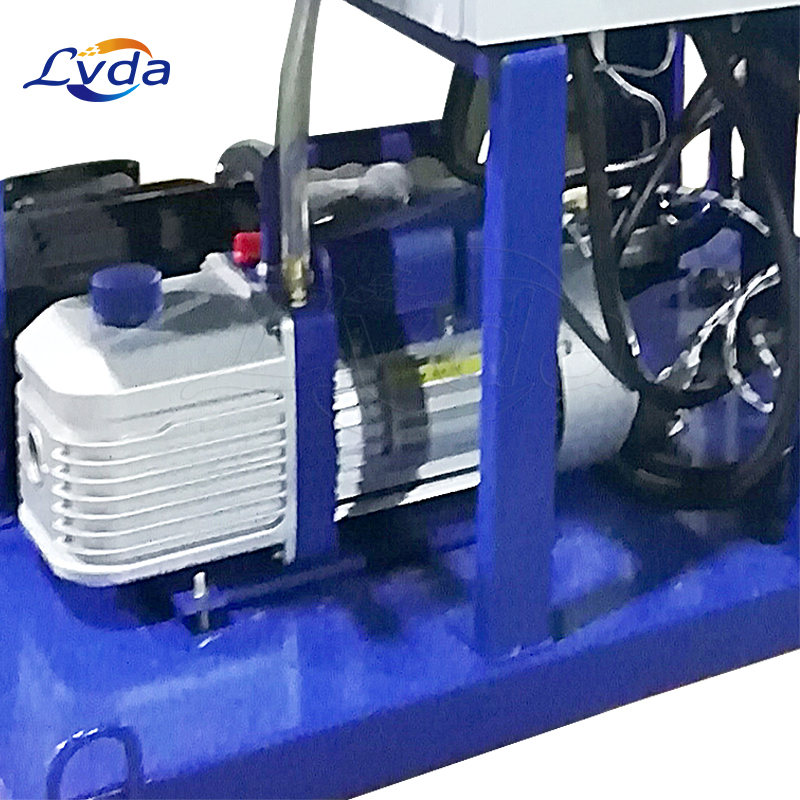

The Vacuum Dehydrator Oil Purification System is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank, a fine filter, a prefilter, a vacuum pump, an oil drain pump and an electrical cabinet. The vacuum pump draws out the air in the vacuum tank to form a vacuum. Under the action of atmospheric pressure, the external oil enters the pre-filter through the oil inlet pipe to remove larger particles, and then enters the heating tank to be heated to 40 ~ 75 ℃. In the vacuum tank, the water in the oil quickly evaporates into water vapor and is continuously sucked into the oil-water separator by the vacuum pump. The water vapor in the separator is cooled and reduced to water and released. The oil in the vacuum heating tank is discharged into the fine filter by the oil discharge pump to filter out the particulate impurities through the filter element. Thereby, the whole process of vacuum filtration to quickly remove impurities, moisture and gas in the oil is completed, so that the clean oil is discharged from the outlet.

Product parameters

Model

| AOP-1V-25

| AOP-1V-32

| AOP-1V-50

| AOP-1V-100

| AOP-1V-150

| AOP-1V-200

|

Flow rate(L/min)

| 25

| 32

| 50

| 100

| 150

| 200

|

Working pressure(Mpa)

|

|

| 0.6

|

|

|

|

Rated vacuum(Mpa)

|

|

| ≤ - 0.095

|

|

|

|

Water content

|

|

| 5 - 30

|

|

|

|

Air content

|

|

| ≤0.2% |

|

|

|

Coarse filtration(μm)

|

|

| 100 |

|

|

|

Grade 1 filter rating(μm)

|

|

| 10、20 |

|

|

|

Grade 2 filter rating(μm)

|

|

| 3/5 |

|

|

|

Pressure differentials

|

|

| 00.2Mpa |

|

|

|

Voltage(V)

|

|

| AC 380V(Three-phase)、50Hz |

|

|

|

Motor power(kw)

| 18 | 26 | 36 | 65 | 65 | 135 |

Weight(kg)

| 360

| 470

| 680

| 840

| 960

| 1500

|

Dimensions (mm) | 12500x920x1600

| 1350x980x1600

| 1500x1060x1800

| 1600x1080x2100

| 1800x1200x2200

| 2000x1200x2200

|

Note: * -is filter's rating,such as 03 is 3 microns.

**-is the suitable medium, Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

****-explosion-proof type: add F before type, Omission: normal type

Product features

Compared with some similar products in the world, this machine has the following characteristics:

1. Small size, light weight, half the weight of similar products.

2. The design of the crude oil gas separator has been improved and perfected. Using vacuum to enter the oil, a tubular rotary fuel injector is installed, which reduces the resistance, speeds up the rotation speed, and increases the oil and gas separation effect.

3. The function of regeneration and purification of metamorphic oil has been added. The previous vacuum oil purifier only removed impurities and moisture. This machine adds a silica gel oil purification system, and integrates silica gel oil purification and impurity filtration into one. After filtering out impurities for mildly deteriorated transformer oil, The adsorption and regeneration of the silica gel oil purifier makes it meet the standard of qualified oil.

4. One machine is multi-functional. This is an important feature of this machine, because the machine is used on site, and the original oil-carrying equipment is used as an oil storage tank, so that the hot oil circulates between the machine and the equipment, so that the oil filtering, regeneration, and hot oil circulation The three functions of drying are carried out at the same time, which saves labor and time.

Product applications

1. This Vacuum Dehydrator Oil Purification System can be used for various oil-immersed transformers, oil-immersed current and voltage transformers and oil-less circuit breakers for on-site oil filtering and oil replenishment.

2. This Vacuum Dehydrator Oil Purification Systemcan be used for on-site hot oil circulation drying of the above equipment, especially for hot oil circulation drying of oil-immersed current, voltage transformers and oil-less circuit breakers.

3. This Vacuum Dehydrator Oil Purification System can be used for on-site vacuum oil injection and oil replenishment and equipment vacuuming for sealed oil-immersed equipment.

4. The Vacuum Dehydrator Oil Purification System can also be used to regenerate and purify the slightly deteriorated transformer oil, so that its performance can meet the qualified oil standard.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português