Product Details

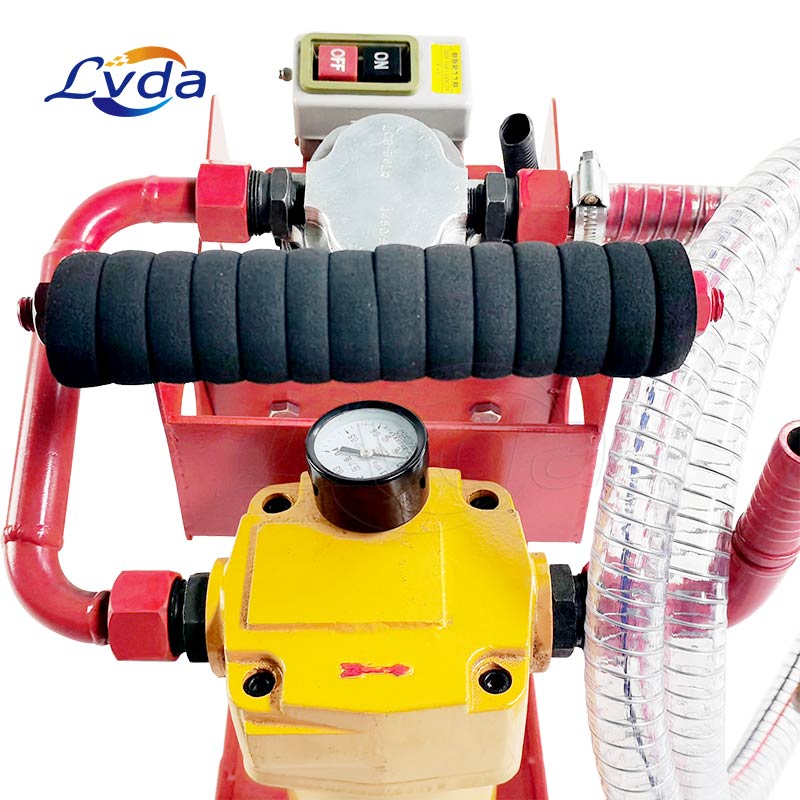

Lube oil filtration portable motor

Guaranteed to Provide Clean Oil Filtration Systems (membrane separation, Microfiltration)

Filtration & Separation Solutions for: Solid Particulate and water removal

Suitable for: Hydraulic oil, engine oil, gear oil (Petroleum or mineral base oil) and lubricating oil

Its design makes it ideally suited to removing reliably in a single-pass 98% of contamination and free & emulsified water to less than 2 ppm, thereby guaranteeing the required cleanliness.

Our Industrial oil filtration system is the ideal way to pre-filter and transfer fluids into reservoirs or to clean up existing systems. Fluid should always be filtered before being put into use.

Solid particle pollution leads to the failure of hydraulic system and lubricating system, so it is necessary to filter the industrial oil before pour it into system. New fluid is not necessarily clean fluid. Most new fluids (right out of the drum) are unfit for use due to high initial contamination levels. Contamination, both particulate and water, may be added to a new fluid during processing, mixing, handling and storage.

Filter elements:

Back-flushable long service life (2-3 years) Filter elements (membrane separation, Microfiltration).

To quickly and reliably achieve very low particle counts in oil to meet or exceed stringent OEM cleanliness specifications, we utilize the latest most efficient elements micro membrane technology. Our filter elements have more media and surface area than other conventional elements, resulting in lower clean initial pressure drops, better filtration performance, higher dirt-holding capacities, and longer life.

The filter elements are sintered and stitched for maximum durability, and are available in a wide variety of micron sizes depending on the particle size distribution within the fuel oil. Micron ratings of 2,5,10,15,20μm.

Parameters

| Model | AOP-6-*/**

| AOP-10-*/**

| AOP-16-*/**

|

Rated flow(L/min) | 6

| 10 | 16 |

Rated pressure(Mpa) | 0.34

|

| Original pressure loss(Mpa) | ≤0.02

|

Coarse filtration accuracy(μm) | 40 meshes

|

Fine filtration accuracy(μm) | 3、 5、 10、 20、 40 |

Alarm differential pressure(MPa) | 0.2MPa |

Use temperature(°C) | 6~80 |

Recommended viscosity for use(cSt) | 10~160 |

Power supply(V) | AC380V three-phase, AC220V three-phase |

Motor Power(kw) | 0.18 | 0.25 | 0.35 |

Weight(kw) | 13 | 16 | 18 |

Dimensions(mm) | 650x680x980

| 650x680x980

| 720x680x1020

|

Note: *- filter precision, such as 003 is 3 microns

**-Filter media, omitted: ordinary hydraulic oil; BH: water glycol; V: phosphate ester hydraulic oil.

Features

-Lightweight and portable

-Extends oil life and Removes water and dirt down to 2 micron from system with one process

-Back-flushable elements reduce frequency of element replacements.

-Pressure gauges give positive indication when filter elements are plugged and need to be changed.

-One person operations

Applications

Filtering new fluid before putting into service

Transferring fluid from drums or storage tanks to system reservoirs

Conditioning fluid that is already in use

Complimenting existing system filtration

Removing free water from a system

For use with fluids such as hydraulic, gear and lube oils

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português