Product Details

Portable oil purifier

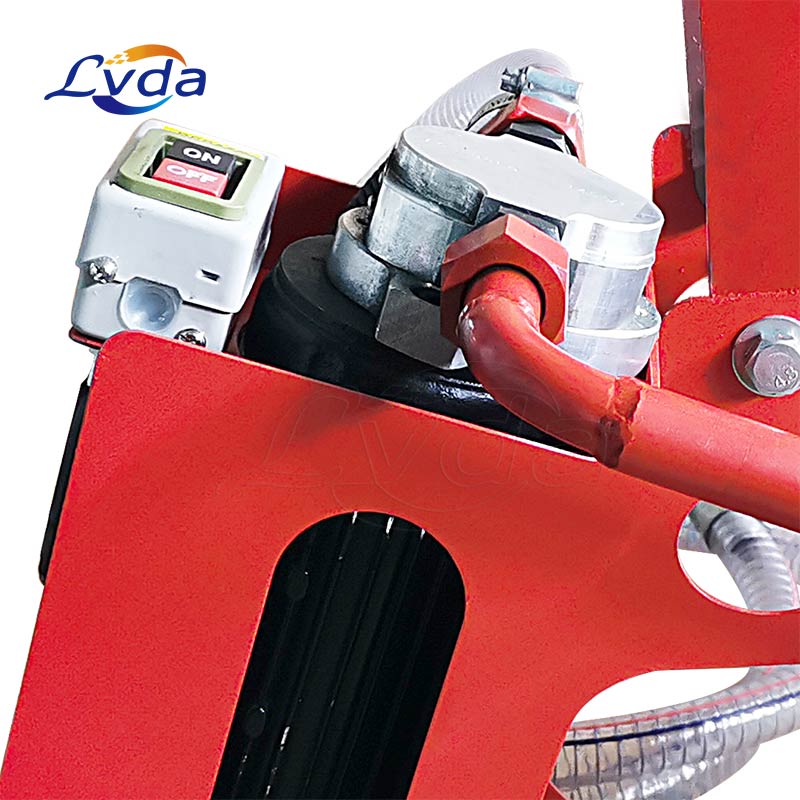

In order to achieve the purpose of small size, light weight and convenient use, the design of the pump and the motor is adopted in the design, and the inlet and outlet and filter oil pipelines are connected by the internal pores of the valve body. Figure 1 The valve body and the pump body are connected by screws and sealed by an O-ring. The oil separator, turntable and vanes are installed in the upper part of the pump body. The lower part of the pump body is connected with the motor without front cover by long bolts, and the output shaft of the motor is extended to the pump body through the bearing support and is connected with the turntable by keys. The upper part of the pump body is filled with filtered oil and does not allow oil to leak to the lower part of the pump body, and is sealed by a rubber sealing ring. There are standard threads on the valve body, which can be connected with filter elements of different filtration precision, and there are threaded holes for installing pressure gauges on the upper part of the valve body. The valve body is connected with the bracket through screws, and the material of the valve body, pump body and bracket is ZL102. The oil inlet port A on the valve body is threaded and connected to the pipe joint with the oil suction hose. The oil to be filtered flows into the valve body through the A port and flows into the pump body from the B port. The oil enters the oil suction chamber through the oil separator, and the oil flows from When the oil pressure chamber is pressed out, it flows back to the valve body through the oil separator through the C port. The oil with pressure is pressed into the standard filter element by the D port through the passage in the valve body to achieve the purpose of filtration and purification. The filtered oil is returned to the valve body through the E port and the oil is discharged through the oil discharge port. The oil outlet E1 is also threaded and connected to the pipe joint with the oil outlet hose. A pressure gauge is installed at the C port that communicates with the oil outlet.

Parameters

| Model | AOP-6-*/**

| AOP-10-*/**

| AOP-16-*/**

|

Rated flow L/min | 6

| 10 | 16 |

Rated pressure Mpa | 0.34

|

| Original pressure loss Mpa | ≤0.02

|

Coarse filtration accuracy μm

| 40 meshes

|

Fine filtration accuracy μm | 3、 5、 10、 20、 40 |

Alarm differential pressure MPa | 0.2MPa |

Use temperature °C | 6~80 |

Recommended viscosity for use cSt | 10~160 |

Power supply V | AC380V three-phase, AC220V three-phase |

Motor Power kw | 0.18 | 0.25 | 0.35 |

Weight kw | 13 | 16 | 18 |

Dimensions mm | 650x680x980

| 650x680x980

| 720x680x1020

|

Note: *- filter precision, such as 003 is 3 microns

**-Filter media, omitted: ordinary hydraulic oil; BH: water glycol; V: phosphate ester hydraulic oil.

Product features

● Small size, light weight, easy to carry and operate.

● The filter precision can be freely selected according to the needs.

Product applications

●Filtering when refueling in hydraulic lubricating system

●Bypass filtration when hydraulic lubrication system works

●Circulating filtration before the hydraulic lubrication system is put into operation

●The oil of the hydraulic lubrication system is not filtered by the pump of the equipment itself and pumped out

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português