Product Details

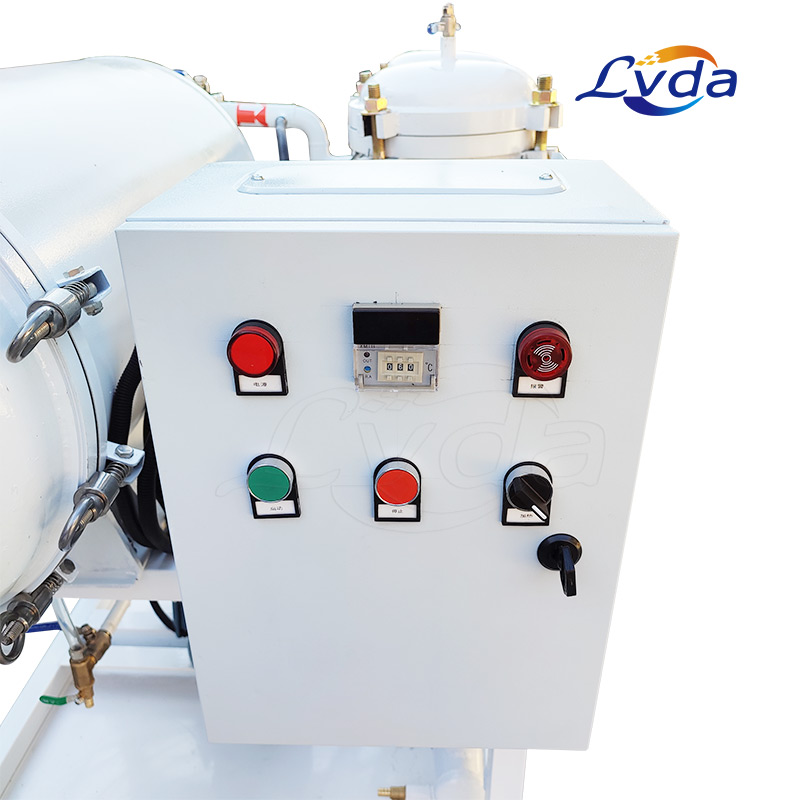

Coalescer fuel & oil filtration system (oil purifier)

In order to effectively and efficiently separate water from fuel, lube oil, turbine oil and hydraulic oil, we have designed coalescer fuel & oil filtration system, this oil purifier machine combines the latest innovations in coalescence separation technology and micro-glass filter media in one system to achieve optimal fluid cleanliness. The high efficiency coalescing and separators filter elements are specifically designed to separate oil from water and water from oil quickly, together with oil mist from air. After separation, overall water content can reach 100 PPM. At the same time, the coalescing oil purifier use high efficiency micro-glass filter elements, they are capable of achieving very low particle counts to as low as NAS 6 grade cleanliness level.

Product parameters

| Model | A0P-D25 | AOP-D50 | A0P-D100 | AOP-D150 | A0P-D200 | AOP-D400 |

| Rated flow(L/min) | 25 | 50 | 100 | 150 | 200 | 400

|

| Rated pressure(MPa) | 0.6 |

| Initial pressure loss (Mpa) | ≤0.1 |

| Filtered water content | ≤100 |

| Coarse filtration( μ m) |

100 |

| Grade 1 filter rating( μ m) | 10、20 |

Grade 2 filter rating( μ m) | 3、5 |

| Pressure differentials | 0.2Mpa |

| Working temperature(°C) | 25- 80 |

| Recommended viscosity(cSt) | 10-120 |

| Voltage(V) | AC 380V(Three-phase)、50Hz |

| Motor power(kw) | 0.75 | 1.1 | 2.2 | 4 | 5.5 | 13

|

| Weight(kg) | 150 | 200 | 300 | 520 | 860 | 2860

|

| Dimensions(mm) | 1200x 800x1250 | 1350 x800x1400 | 1740x 980x1450 | 1800x1000x1540 | 1840x1050x1780 | 3180x 1600x2000 |

Note: *-is filter's rating,such as 03 is 3 microns.

**-is the suitable medium,Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

***-explosion-proof type: add F before type, Omission: normal type

Product features

-Designed for use on turbine lube oil, hydraulic oil, diesel fuel, heat transfer oil, dielectric oil etc.

-The coalescence oil separator elements are normally constructed using a pre-filter stage to protect the coalesce filters.

-Cart type, light weight, simple and reliable operation, low maintenance cost.

-Removing particles down to NAS 6 grade cleanness level

-Rapidly removing large amount free & emulsified water from oil and as low as 100 PPM.

Product applications

Mechanical processing, metallurgical industry, petrochemical industry, cement plant, electric power industry, iron and steel industry, paper industry, textile industry, purification of turbine oil and transformer oil; water removal and impurity removal of oil in hydraulic lubrication system; comprehensive access to hydraulic lubrication system Improve system cleanliness.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português