Product Details

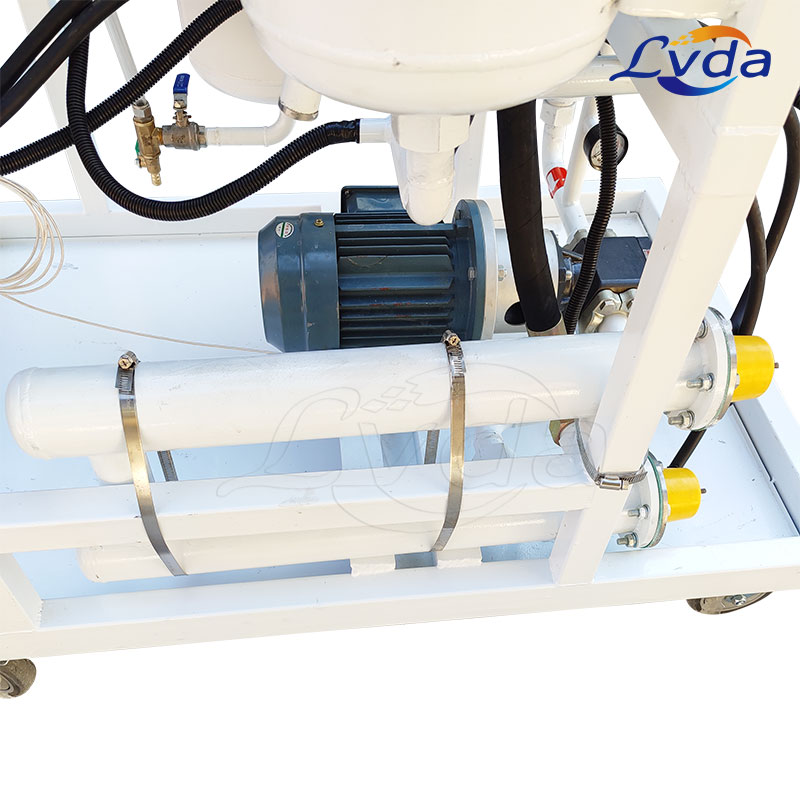

Coalescing dewatering purifier for turbine oil

Technical principle: Different liquids have different surface tensions. When different mixed liquids flow into the separator, they first enter the coalescing filter element. Due to the difference in surface tension, the oil quickly passes through the filter layer.

The coalescing dewatering purifier for turbine oil is a combination of precision filtration and dehydration. The introduction of foreign "coalescence separation" technology for dehydration, high dehydration efficiency, strong capacity, filtration accuracy can reach NAS4-6 level, especially suitable for the separation of a large amount of water in the oil, far better than the dehydration capacity of the centrifugal method, It can break all the oil-water emulsification structure in the medium;

coalescing dewatering purifier for turbine oil, the coalescing filter element is made of hydrophilic material, tiny water droplets are adsorbed on the surface of the filter layer to cause the coalescing of the water droplets, and sedimentation is separated from the oil under the action of gravity, and the oil after passing through the coalescing filter element , there are still small-sized water droplets forward to the separation filter element under the action of inertia. The separation filter element is made of special hydrophobic material. When the oil passes through, the water droplets are blocked from the outside of the separation filter element, and the oil is discharged from the outlet through the separation filter element. Through the filtration of the particle filtration system, the cleanliness of the medium can be stably controlled in the state required by the system to ensure the cleanliness of the oil; it does not change the physical and chemical properties of the oil and prolongs the service life of the oil; low energy consumption , low operating cost; excellent system configuration, strong continuous work performance, suitable for online operation.

Product parameters

| Model | A0P-D25 | AOP-D50 | A0P-D100 | AOP-D150 | A0P-D200 | AOP-D400 |

| Rated flow(L/min) | 25 | 50 | 100 | 150 | 200 | 400

|

| Rated pressure(MPa) | 0.6 |

| Initial pressure loss (Mpa) | ≤0.1 |

| Filtered water content | ≤100 |

| Coarse filtration( μ m) |

100 |

| Grade 1 filter rating( μ m) | 10、20 |

Grade 2 filter rating( μ m) | 3、5 |

| Pressure differentials | 0.2Mpa |

| Working temperature(°C) | 25- 80 |

| Recommended viscosity(cSt) | 10-120 |

| Voltage(V) | AC 380V(Three-phase)、50Hz |

| Motor power(kw) | 0.75 | 1.1 | 2.2 | 4 | 5.5 | 13

|

| Weight(kg) | 150 | 200 | 300 | 520 | 860 | 2860

|

| Dimensions(mm) | 1200x 800x1250 | 1350 x800x1400 | 1740x 980x1450 | 1800x1000x1540 | 1840x1050x1780 | 3180x 1600x2000 |

Note: *-is filter's rating,such as 03 is 3 microns.

**-is the suitable medium,Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

***-explosion-proof type: add F before type, Omission: normal type

Product features

Coalescing dewatering purifier for turbine oil, installed three stage cartridge filter elements, they can remove different sizes of particles from diry oil, such as lubricant oil, hydraulic turbine oil, insulation oil, transformer oil, diesel fuel oil. Different types of filter elements availabe for different oil request.

Precise three-stage filter system can filter the mechanical impurities as well as satisfy the need of long distance and high lift refueling and exhausting oil.

It is an effective oil filtering equipment to control the pollution degree of turbine hydraulic lubricant system

Product applications

*Purification of turbine oil and transformer oil

*Water removal and impurity filtration of oil in hydraulic lubrication system

*Access to hydraulic lubrication systems and comprehensively improve system cleanliness

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português