Product Details

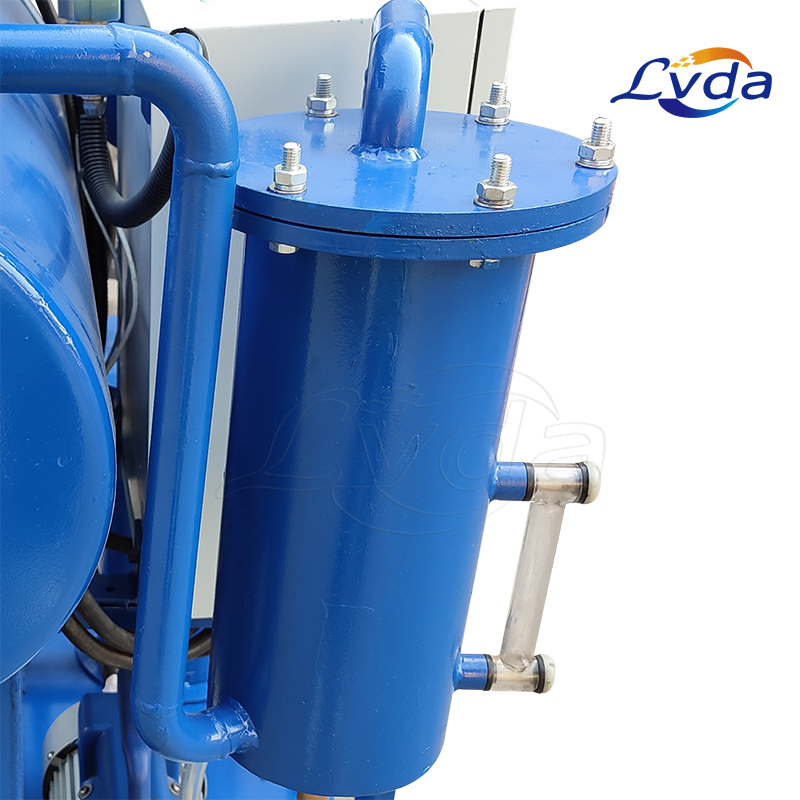

Vacuum turbine lube oil purifier

Vacuum turbine lube oil purification system is a special device for the purification of lube oil quality such as turbine oil, lubricating oil and cooling oil that needs to remove a large amount of water and impurity.

During the long-term operation of industrial equipment, moisture, impurities and mechanical particles will be mixed into the lubrication system due to various reasons, which can easily lead to the corrosion and wear of the metal parts of the unit, which reduces the lubrication performance of the lube oil and affects the safe operation of the unit.

The vacuum turbine lube oil purification system is equipped with a special demulsification filter element, a water removal and acid removal filter element, which can effectively remove a large amount of water, impurities, metal particles, acidic substances, varnish, etc. in the turbine oil and other lubricating oils to ensure the cleanliness of the oil. Extend the service life of steam turbines and other equipment.

Product parameters

Model

| AOP-1V-25

| AOP-1V-32

| AOP-1V-50

| AOP-1V-100

| AOP-1V-150

| AOP-1V-200

|

Flow rate(L/min)

| 25

| 32

| 50

| 100

| 150

| 200

|

Working pressure(Mpa)

|

|

| 0.6

|

|

|

|

Rated vacuum(Mpa)

|

|

| ≤ - 0.095

|

|

|

|

Water content

|

|

| 5 - 30

|

|

|

|

Air content

|

|

| ≤0.2% |

|

|

|

Coarse filtration(μm)

|

|

| 100 |

|

|

|

Grade 1 filter rating(μm)

|

|

| 10、20 |

|

|

|

Grade 2 filter rating(μm)

|

|

| 3/5 |

|

|

|

Pressure differentials

|

|

| 00.2Mpa |

|

|

|

Voltage(V)

|

|

| AC 380V(Three-phase)、50Hz |

|

|

|

Motor power(kw)

| 18 | 26 | 36 | 65 | 65 | 135 |

Weight(kg)

| 360

| 470

| 680

| 840

| 960

| 1500

|

Dimensions(mm) | 12500x920x1600

| 1350x980x1600

| 1500x1060x1800

| 1600x1080x2100

| 1800x1200x2200

| 2000x1200x2200

|

Note: * -is filter's rating,such as 03 is 3 microns.

**-is the suitable medium, Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate

hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

****-explosion-proof type: add F before type, Omission: normal type

Product features

Oil flow range from 600 liters/hour up to 18000 liters/hour for selection according to the actual demands.

Exclusive degassing technology, several times the area of traditional evaporation methods, and twice the residence time of traditional evaporation.

The precision of the fine filter element is optional from 1 to 5 microns, β≥1000, and the solid particle retention rate is as high as 99.99%.

Demulsifying chamber is designed especially for emulsion breaking, it makes up for the technical defect that the centrifuge cannot remove emulsified water.

Electrical heater is equipped with thermostat, avoid overheating of turbine oil.

Design of thermal vacuum (vacuum & heating) to promote the efficiency of turbine oil dehydration.

Equipped with a motor overload protection device to protect the safe operation of the motor.

Mobile Type, Continuous working and available for online processing of turbine oil after connecting with the lubricating oil tank of steam turbine.

Power supply can be customized according to your local power.

Product applications

Metallurgy, mechanical oilfield, chemical, mining, electric power, transportation, manufacturing and other industries purify hydraulic oil, hydraulic transmission oil, gear oil, compressor oil, refrigeration oil, heat treatment oil, diesel oil, heat transfer oil, coking oil, etc.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português