Product Details

Vacuum Oil Filtration and Dehydration Unit

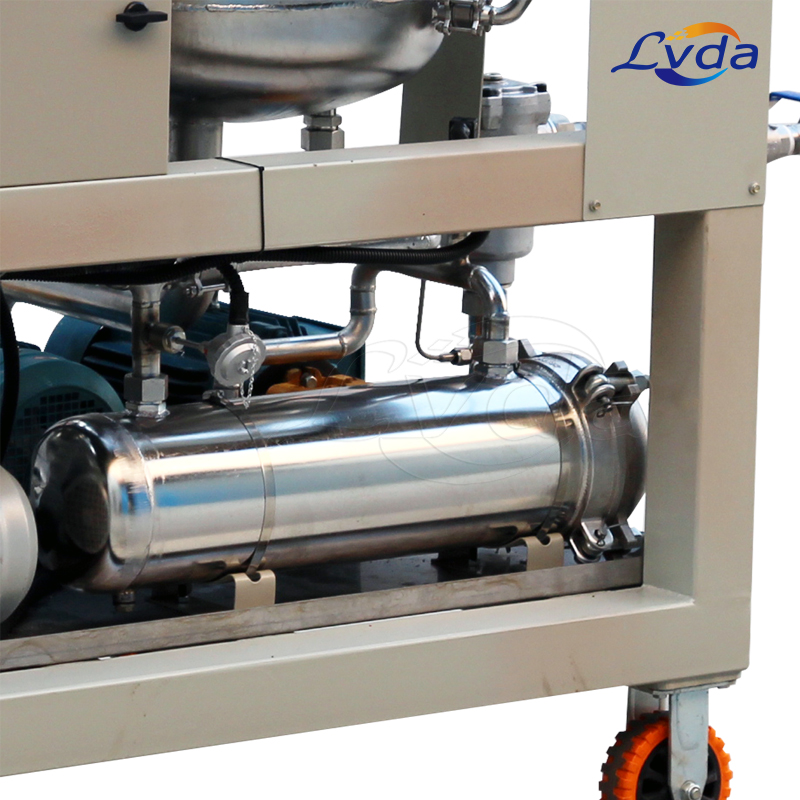

Vacuum oil filtration and Dehydration Unit is also known as vacuum high-efficiency oil filter, oil filter, vacuum oil purifier. Vacuum oil filtration and Dehydration Unit has the characteristics of small size, light weight, convenient movement, low noise, long continuous working time, stable performance and convenient operation. It is ideal for power plants, power stations, substations, electrical manufacturing plants, oil refineries, petrochemical and other industrial and mining enterprises to filter moisture, gas and impurity particles in transformer oil, turbine oil, engine oil below 40#, hydraulic oil and other oils. equipment.

Vacuum oil filtration and Dehydration Unit is designed according to the different boiling points of water and oil. It consists of vacuum heating tank fine filter, condenser, primary filter, water tank, vacuum pump, oil drain pump and electrical cabinet. The vacuum pump draws out the air in the vacuum tank to form a vacuum. Under the action of atmospheric pressure, the external oil enters the primary filter through the inlet pipe to remove larger particles, and then enters the heating tank. After heating, the oil at 40~75 ℃ passes through. Automatic oil float valve, this valve is to automatically control the balance of oil in and out of the vacuum tank. The heated oil is separated into a semi-mist by the rapid rotation of the jet wing, and the water in the oil is rapidly evaporated into water vapor and continuously sucked into the condenser by the vacuum pump. The water vapor entering the condenser is cooled and then returned to the original water and released. The oil in the vacuum heating tank is discharged into the fine filter by the oil discharge pump to filter out the particulate impurities through the oil filter paper or filter element, so as to complete the vacuum oil filter quickly. The whole process of removing impurities, moisture and gas in the oil makes the clean oil drain out of the machine from the oil outlet.

Product parameters

Model

|

AOP-1V-25

|

AOP-1V-32

|

AOP-1V-50

|

AOP-1V-100

|

AOP-1V-150

|

AOP-1V-200

|

Flow rate(L/min)

|

25

|

32

|

50

|

100

|

150

|

200

|

Working pressure(Mpa)

|

|

|

0.6

|

|

|

|

Rated vacuum(Mpa)

|

|

|

≤ - 0.095

|

|

|

|

Water content

|

|

|

5 - 30

|

|

|

|

Air content

|

|

|

≤0.2% |

|

|

|

Coarse filtration(μm)

|

|

|

100 |

|

|

|

Grade 1 filter rating(μm)

|

|

|

10、20 |

|

|

|

Grade 2 filter rating(μm)

|

|

|

3/5 |

|

|

|

Pressure differentials

|

|

|

00.2Mpa |

|

|

|

Voltage(V)

|

|

|

AC 380V(Three-phase)、50Hz |

|

|

|

Motor power(kw)

|

18 |

26 |

36 |

65 |

65 |

135 |

Weight(kg)

|

360

|

470

|

680

|

840

|

960

|

1500

|

Dimensions

(mm) |

12500x920x1600

|

1350x980x1600

|

1500x1060x1800

|

1600x1080x2100

|

1800x1200x2200

|

2000x1200x2200

|

Note: * -is filter's rating,such as 03 is 3 microns.

**-is the suitable medium, Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate

hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

****-explosion-proof type: add F before type, Omission: normal type

Product features

Flow Rates:

3, 5, 10, 15, and 20gpm are the most common models.

Permanent Dispersion Media:

Located in the vacuum tower to maximize water extraction rates and eliminate the need for costly replacement of coalescing elements, while enabling the system to operate effectively on high-viscosity gear oils.

Rotary Claw Vacuum Pump:

High-quality specialty pump pulls deeper vacuum and higher CFM, and requires less maintenance than other conventional vacuum pumps.

Variable Frequency Drive:

Enables operator to dial in the optimal flow rate and enhances the system’s overall performance during cold start-ups, on higher viscosity oils, or when a restricted inlet condition exists.

Single Utility:

Requires electric service only—not a chilled water supply.

System View Windows:

Enables operator to observe system operation and performance.

Filter Change Indicator Light:

Positive indication when the particulate removal filter element is plugged and needs to be changed.

Additional Options:

Transformer oil filtration option, low and high vacuum options, skid or caster mounts.

Product applications

Filtering hydraulic systems

Filtering steam turbine lube systems

Almost any industrial equipment containing oil

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português