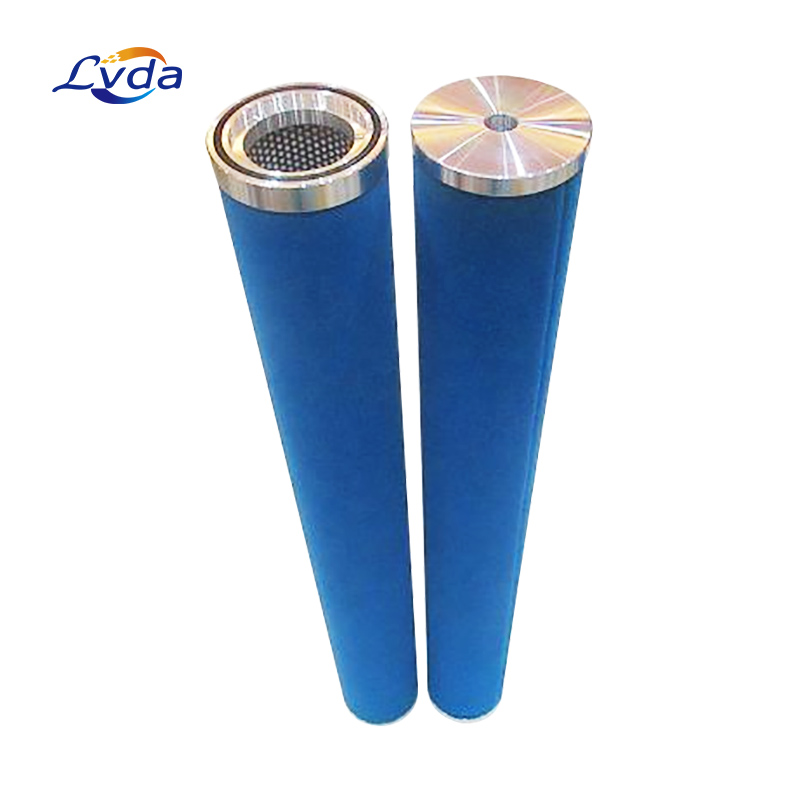

Product Details

AIRFILTER

The air filter is an important part of the air intake system of the air compressor, which consists of an assembly of several air filter elements

FUNCTION

Its main function is to filter out the harmful impurity particles that will enter the air compressor screw,ensure sufficient and clean air to enter the air compressor, reduce the wear of the air compressor screw, bearing, cylinder liner,etc, and prolong the service life of the equipment.

The filtration efficiency is high, which can effectively ensure the reliable operation of the air compressor; The intake resistance is low, the intake resistance is small,so that sufficient air can be supplied.The ash storage capacity is strong, reduces the maintenance times of the air filter, and reduces the cost of use.

Particulate (After-Filter) Filters

A particulate filter, also known as an after-filter, is usually located just after the desiccant air dryer to remove harmful liquid oil, water condensate, pipe scale,dirt and rust from your compressed air system. This helps preventscontaminants & corrosive damage to compressed air equipment and finished products. If the particulate filter gets soiled more frequently than what is typical for your environment, it may be time to replace the desiccant.

Product features

1. High porosity, good air permeability, low resistance and low pressure difference;

2. After forming into a folded shape, the filtering area is large and the dirt holding capacity is large;

3.Thickened material, high-precision sponge, high temperature resistance, corrosion resistance, suitable for high viscous liquid filtration, long service life;

4. Good regeneration performance, can be used repeatedly after chemical cleaning, high temperature and ultrasonic cleaning;

5. All stainless steel structure, wide chemical compatibility;

6. Built-in high-quality sealing ring, good sealing performance;

7. Industrial casting strictly controls the production details to control the error and control the error within an acceptable range.

Product parameters

Model Number | E9-32 E9-36 E9-40 E9-44 E9-48 |

Type | dryer filter;coarse filtration;compressed air filter |

Dimension | Standard |

Working Temperature | According to customer's request |

Work Pressure Different | Customized |

Material | Glassfiber, Stainless steel, Filter paper |

Filter Precision | 0.01-3μm |

Life span | 6000- 8000h |

Porosity | 1um |

Weight | 0.4kg |

Package size: | 10*10*35CM |

Certificate | ISO9001 |

Maximum Oil Carryover | 5 ppm Oil Removal |

Efficiency | 99.99% |

Advantages | 1.Adopt imported glassfiber media |

2.High filtration effciency over 99.9% |

Grade | Filtrationg rating (μm) | Oil content |

(ppm) |

E1 | 0.01 | 0.001 |

E3 | 0.01 | 0.001 |

E5 | 0.01 | 0.01 |

E7 | 1 | 1 |

E9 | 3 | 5 |

Grade | E1 | E3 | E5 | E7 | E9 |

Flow rate (NM3/MIN) |

0.57 | E1-12 | E3-12 | E5-12 | E7-12 | E9-12 |

1 | E1-16 | E3-16 | E5-16 | E7-16 | E9-16 |

1.72 | E1-20 | E3-20 | E5-20 | E7-20 | E9-20 |

2.9 | E1-24 | E3-24 | E5-24 | E7-24 | E9-24 |

4.9 | E1-28 | E3-28 | E5-28 | E7-28 | E9-28 |

7.2 | E1-32 | E3-32 | E5-32 | E7-32 | E9-32 |

11 | E1-36 | E3-36 | E5-36 | E7-36 | E9-36 |

14 | E1-40 | E3-40 | E5-40 | E7-40 | E9-40 |

18 | E1-44 | E3-44 | E5-44 | E7-44 | E9-44 |

22 | E1-48 | E3-48 | E5-48 | E7-48 | E9-48 |

Product application

1. Metallurgy: It is used for the filtration of the hydraulic system of rolling mills and continuous casting machines and the filtration of various lubricating equipment.

2. Petrochemical: used for separation and recovery of finished products and intermediate products in the process of oil refining and chemical production, liquid purification, purification of magnetic tapes, optical discs and photographic films in manufacturing, oil field well injection water and natural gas for particle removal and filtration.

3. Textiles, electronics and pharmaceuticals

4. Power Plant

5. Steel mills

6. Subway engineering

7. Chemical plant

8. Ships

9. Paper mill

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português