Product Details

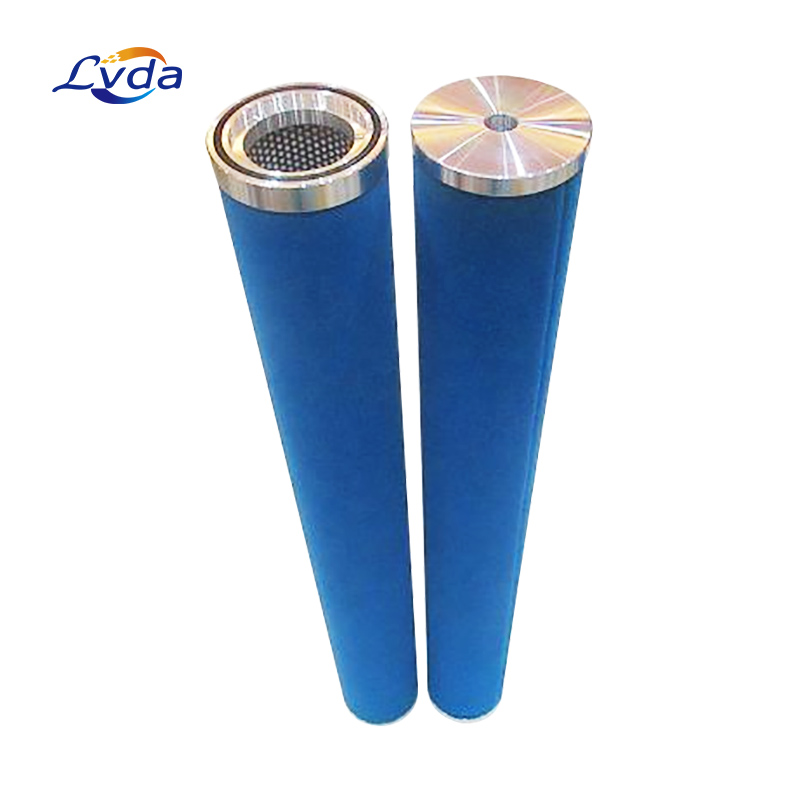

The air filter produced by our company can completely replace the original product. It is completely made with drawings. The components of the filter element are composed of upper and lower plastic end caps, inner and outer stainless steel skeleton, middle glass fiber and filter paper. Its parameters, structure and size are exactly the same as the original one, and there are domestic filter elements and imported filter materials in the selection of filter materials,which is suitable for the requirements of air pressure pipelines in various industries and can give customers different choices.Compared to the original products, the price is more favorable, the quality is high, and it has has an ultra-high cost performance ratio.

Hankison precision filter element is the core component of compressed air treatment. The precision filter element made of stainless steel support and imported glass fiber can intercept impurities and tiny oil droplets above 0.01 microns in the compressed air. The sponge wrapped on the outside can effectively prevent the intercepted oil droplets from being taken away, thereby improving the cleanliness of the compressed air and controlling the oil content of the compressed air below 0.01ppm.

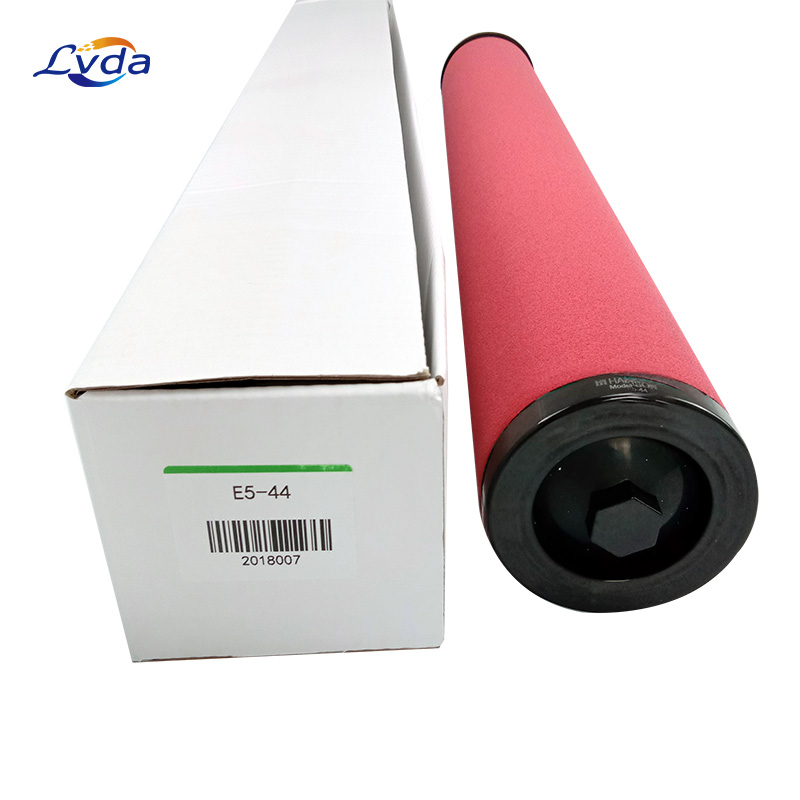

The HANKISON E5-44 filter element replacement is built with the highest quality materials and workmanship. This coalescing filter element offers equal to or better filtration performance based on the original OEM filter specifications.

Coalescing filter elements are used to remove water, oil vapor and other contaminants from a compressed air line. These coalescing filters provide the highest level of clean compressed air with a minimum loss of pressure. Our coalescing filter elements are tough enough to hold their shape under pressure and maintain even pressure differentials to avoid collapsing of the filter element.

The HANKISON E5-44 filter element equivalent is manufactured with the highest quality standards including: ANSI / CAGI Institute ADF 400-1999 Compressed Air and Gas, ISO / FDIS 8573-4 and code number of sale 1DJ40 U.S. Government.

Grade 5: High Eff. Oil Removal. Designed for coalescing fine water and oil aerosols, this filter removes solid particulate to 0.01 microns with a 0.008 ppm w/w maximum remaining oil content (established in accordance with CAGI standard ADF400 and is based on 100°F inlet temperature). The first stage of filtration uses multiple layers of fiber media and screen to remove larger particles, pre-filtering the air, while the second stage utilizes multiple layers of bonded, blended fiber media for fine coalescence. Grade 5: High Eff. Oil Removal. Designed for coalescing fine water and oil aerosols, this filter removes solid particulate to 0.01 microns with a 0.008 ppm w/w maximum remaining oil content (established in accordance with CAGI standard ADF400 and is based on 100°F inlet temperature). The first stage of filtration uses multiple layers of fiber media and screen to remove larger particles, pre-filtering the air, while the second stage utilizes multiple layers of bonded, blended fiber media for fine coalescence.

Product features

1. High porosity, good air permeability, low resistance and low pressure difference;

2. After forming into a folded shape, the filtering area is large and the dirt holding capacity is large;

3. Thickened material, high-precision sponge, high temperature resistance, corrosion resistance, suitable for high viscous liquid filtration, long service life;

4. Good regeneration performance, can be used repeatedly after chemical cleaning, high temperature and ultrasonic cleaning;

5. All stainless steel structure, wide chemical compatibility;

6. Built-in high-quality sealing ring, good sealing performance

7. Industrial casting strictly controls the production details to control the error and control the error within an acceptable range

8.Beautiful design,high pressure stability,used for air compressor,high precision and high filtration

Product parameters

| Flow | E1 | E3 | E5 | E7 | E9 |

| m3/min |

| 1 | E1-12 | E3-12 | E5-12 | E7-12 | E9-12 |

| 2 | E1-20 | E3-20 | E5-20 | E7-20 | E9-20 |

| 3 | E1-24 | E3-24 | E5-24 | E7-24 | E9-24 |

| 4.9 | E1-28 | E3-28 | E5-28 | E7-28 | E9-28 |

| 6;7.2 | E1-32 | E3-32 | E5-32 | E7-32 | E9-32 |

| 11 | E1-36 | E3-36 | E5-36 | E7-36 | E9-36 |

| 14 | E1-40 | E3-40 | E5-40 | E7-40 | E9-40 |

| 18 | E1-44 | E3-44 | E5-44 | E7-44 | E9-44 |

| Precision code | Precision | Residual oil |

| (μm) | (ppm) |

| E1 | 0.01 | 0.001 |

| E3 | 0.01 | 0.001 |

| E5 | 0.01 | 0.01 |

| E7 | 1 | 1 |

| E9 | 3 | 5 |

model | Level | Handling capacity | Outer diameter | height | Total height |

*-16 | E1 E3 E5 E7 E9 | 1.6m³/min | 44mm | 98mm | 136mm |

*-20 | E1 E3 E5 E7 E9 | 2.6m³/min | 44mm | 155mm | 193mm |

*-24 | E1 E3 E5 E7 E9 | 4.0m³/min | 60mm | 165mm | 230mm |

*-28 | E1 E3 E5 E7 E9 | 4.8m³/min | 68mm | 276mm | 340mm |

*-32 | E1 E3 E5 E7 E9 | 7.0m³/min | 68mm | 339mm | 405mm |

*-36 | E1 E3 E5 E7 E9 | 11.5m³/min | 68mm | 446mm | 517mm |

*-40 | E1 E3 E5 E7 E9 | 15.0m³/min | 83mm | 511mm | 596mm |

*-44 | E1 E3 E5 E7 E9 | 20.0m³/min | 83mm | 666mm | 742mm |

*-48 | E1 E3 E5 E7 E9 | 25.0m³/min | 83mm | 778mm | 854mm |

Product application

1. Metallurgy: It is used for the filtration of the hydraulic system of rolling mills and continuous casting machines and the filtration of various lubricating equipment.

2. Petrochemical: used for separation and recovery of finished products and intermediate products in the process of oil refining and chemical production, liquid purification, purification of magnetic tapes, optical discs and photographic films in manufacturing, oil field well injection water and natural gas for particle removal and filtration.

3. Textiles, electronics and pharmaceuticals

4. Power Plant

5. Steel mills

6. Subway engineering

7. Chemical plant

8. Ships

9. Paper mill

10. spraying

11.hydraulic machinery

12.automobile

13.Pre filters for painting, injection molding, instruments and control valves,Prefilter of suction dryer,Post filter of refrigeration dryer,Post filter of adsorption dryer

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português