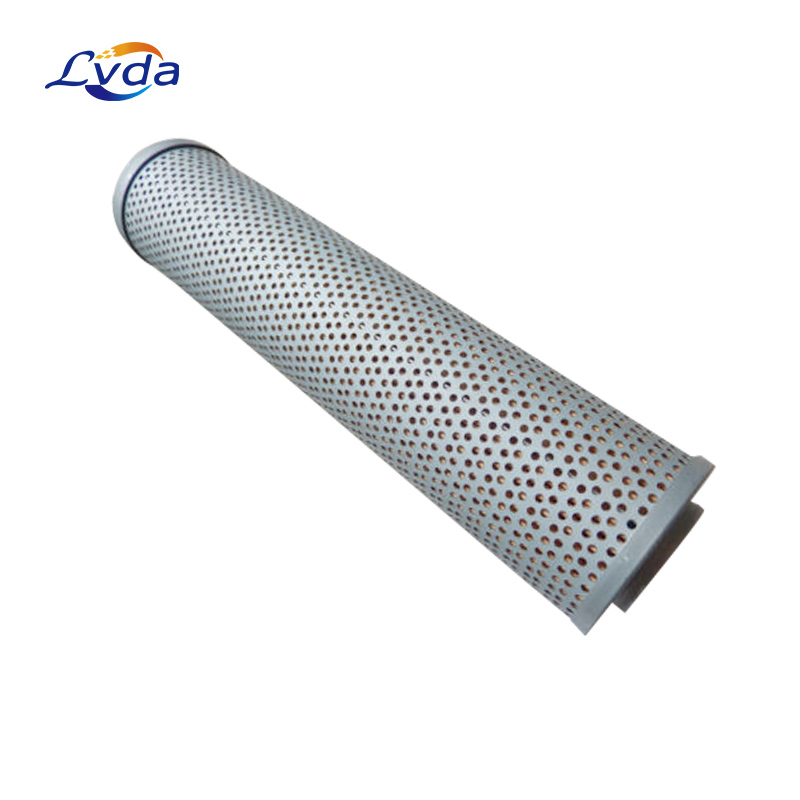

Product Details

During the use of the hydraulic oil filter, due to various reasons, some impurities will be mixed in. The main impurities are mechanical impurities, water and air. These impurities will cause accelerated corrosion, increase mechanical wear, reduce work efficiency, deteriorate oil products, and reduce the service life of the equipment. In severe cases, the oil circuit will be blocked, causing production accidents.

The filter element is used to protect specific components in the hydraulic system. It is installed upstream of the components to be protected in the medium pressure pipeline to filter solid particles and colloidal substances in the working medium, effectively control the pollution degree of the working medium, and make the components work normally. The hydraulic oil filter element is mainly made of stainless steel woven mesh, sintered mesh, and iron woven mesh. Because the filter materials used are mainly glass fiber filter paper, chemical fiber filter paper, and wood pulp filter paper, it has the characteristics of high concentricity, large pressure bearing, good straightness, stainless steel material, no burrs, and long service life. Its structure is made of single-layer or multi-layer metal mesh and filter materials, In specific use, the number of layers and mesh of the screen are determined according to different use conditions and purposes.

Product features

1. OEM quality standard guaranteed.

2.Product upgrading and expansion of species.

3.Good quality with competitive prices.

4.Flexible and convenient logistic service.

5.Excellent and high-quality control.

6.Long lasting working life time.

Product parameters

Model | V3.0510-06K4 |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 4000H |

Certificate | ISO9001:2015 |

Quality | 100% Tested |

Weight | 0.15 kg |

Flow | 50 l/min |

Maximum pressure | 400 bar |

Degree of filtration | 12µm - 10EX2 |

Size: | 45*20*104 |

Precision: | 10 micron |

Material: | glass fiber |

Product application

1. Metallurgy: It is used for filtering the hydraulic system of steel rolling mill and continuous casting machine and filtering various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in oil refining and chemical production, particle removal and filtration of oilfield well water and natural gas.

3. Textile: purification and uniform filtration of polyester melt during wire drawing, protective filtration of air compressor, oil and water removal of compressed gas.

4. Electronics and pharmacy: pretreatment filtration of reverse osmosis water and deionized water, pretreatment filtration of cleaning solution and glucose.

5. Thermal power and nuclear power: purification of lubricating system, speed control system and bypass control system oil of gas turbine and boiler, and purification of feed pump, fan and dust removal system.

6. Mechanical processing equipment: lubrication system and compressed air purification of paper machinery, mining machinery, injection molding machines and large precision machinery, and dust recovery and filtration of tobacco processing equipment and spraying equipment.

7. Railway internal combustion engine and generator: filtering of lubricating oil and engine oil.

8. Automobile engine and construction machinery: air filter, oil filter, fuel filter for internal combustion engine, various hydraulic oil filters, diesel oil filters and water filters for construction machinery, ships and trucks.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português