Product Details

The substitute ARGO series is installed in the oil circuit of the hydraulic system to remove the metal powder and other mechanical impurities worn by various components in the hydraulic system to keep the oil circuit clean, which can extend the service life of the hydraulic system; The low pressure series filter element is also equipped with a bypass valve. When the hydraulic oil filter element is not replaced in time, the bypass valve can automatically open to ensure the normal operation of the system.

In the hydraulic system, it is used to filter solid particles and colloidal substances in the working medium and effectively control the pollution degree of the working medium. This series of filter element is a home-made substitute for the filter element for imported equipment, which can replace the original imported ARGO filter element.

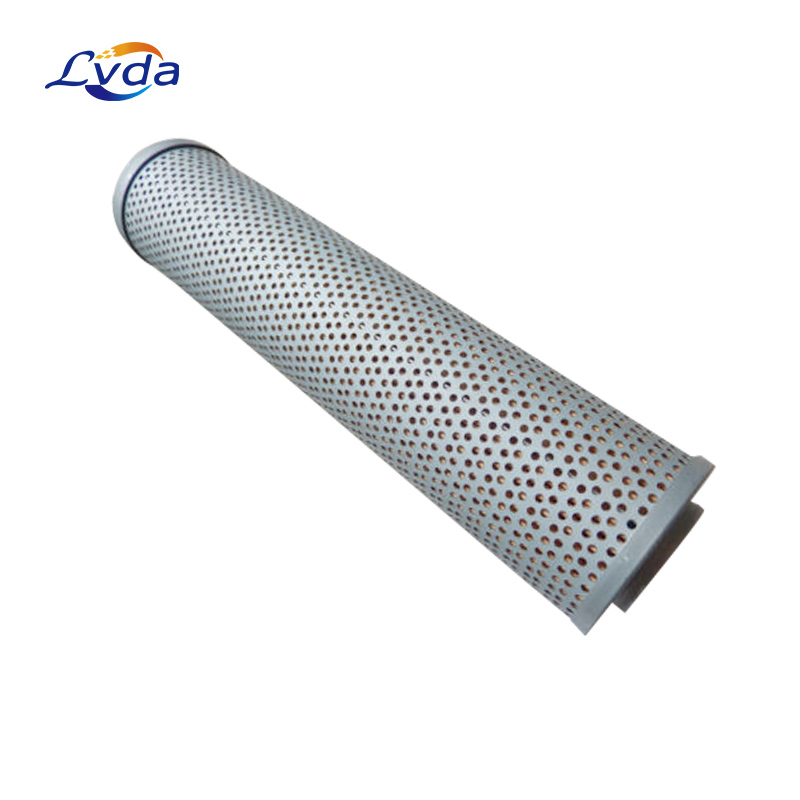

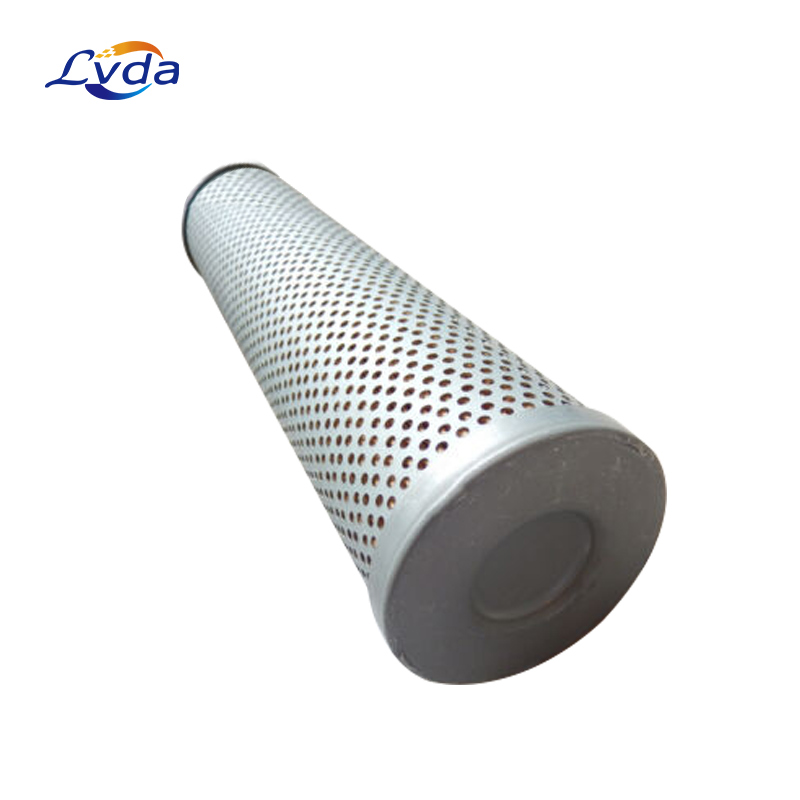

By means of full-fl ow filtration in the system return, the pumps above all are protected from dirt particles remaining in the system after assembly, repairs, or which are generated by wear or enter the system from outside.Flow direction from outside to centre.

Product features

1.large filter surfaces

2.low pressure drop

3.high dirt-holding capacities

4.long service life

Product parameters

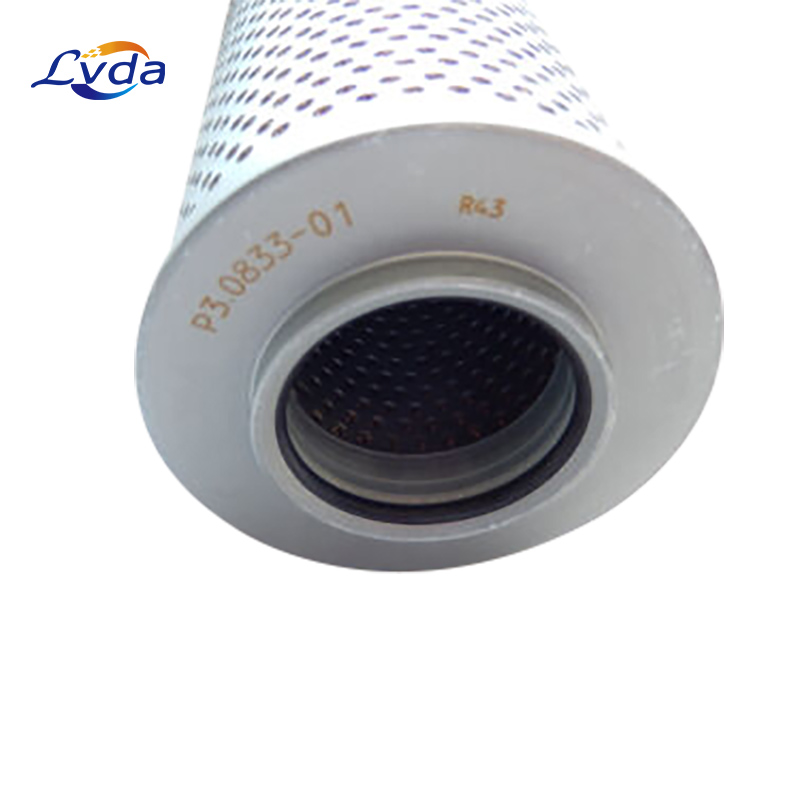

| Model: | P3.0833-01 |

| Place of Origin: | Henan, China |

| Brand Name: | LVDA |

| Life span: | 6000- 8000h |

| Certificate: | ISO9001 |

| Quality: | 100% Tested |

| Working pressure: | -21~210 bar |

| Micron Rating: | 10 |

| Direction of Flow: | OUTSIDE->IN |

| Recommended Changeout Differential Pressure: | 20 PSID |

| Outer Diameter, Top: | 78 MM |

| Inner Diameter, Top: | 40 MM |

| Length: | 332 MM |

| Type of Endcap: | PLATED STEEL |

| Type of Media: | FILTER PAPER |

Product application

1. Metallurgy: It is used for filtering the hydraulic system of steel rolling mill and continuous casting machine and filtering various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in the process of oil refining and chemical production, purification of liquid, tape, optical disk and photographic film in manufacturing, and filtration of oilfield well water and natural gas.

3. Textile: purification and uniform filtration of polyester melt during wire drawing, protective filtration of air compressor, oil and water removal of compressed gas.

4. Electronics and pharmacy: pretreatment filtration of reverse osmosis water and deionized water, pretreatment filtration of cleaning solution and glucose.

5. Thermal power and nuclear power: purification of lubricating system, speed control system and bypass control system oil of gas turbine and boiler, and purification of feed pump, fan and dust removal system.

6. Mechanical processing equipment: lubrication system and compressed air purification of paper machinery, mining machinery, injection molding machines and large precision machinery, and dust recovery and filtration of tobacco processing equipment and spraying equipment.

7. Railway internal combustion engine and generator: filtering of lubricating oil and engine oil.

8. Automobile engine and construction machinery: air filter, oil filter, fuel filter for internal combustion engine, various hydraulic oil filters, diesel oil filters and water filters for construction machinery, ships and trucks.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português