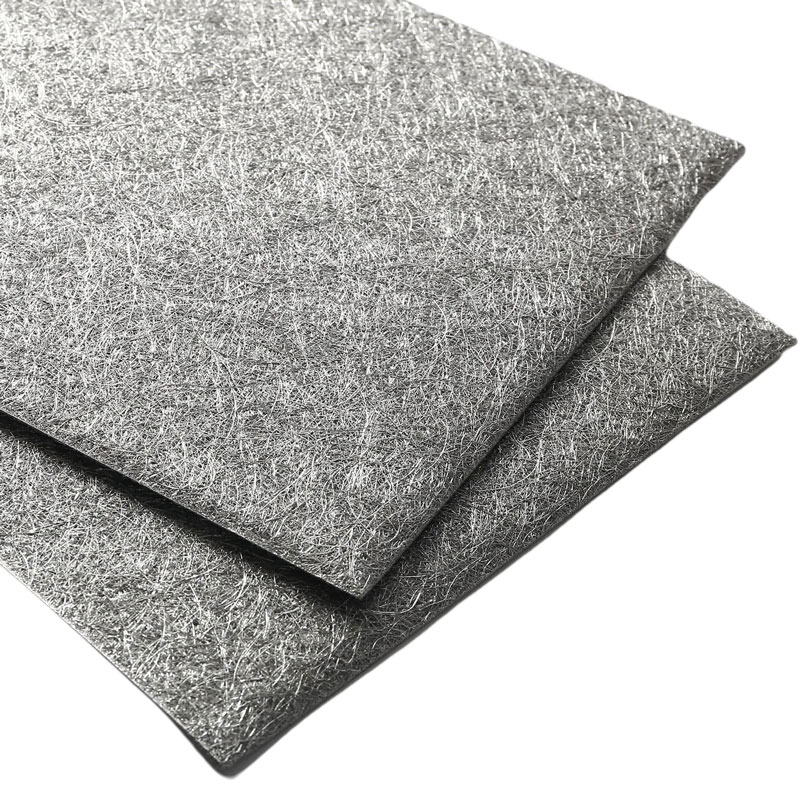

Stainless steel sintered felt is also called metal sintered felt, metal fiber felt, sintered felt, It is made of extremely fine stainless steel metal fiber (accurate to micron in diameter) which is made by non-woven layering and superimposed by high temperature sintering. Due to the above structure and features, made of stainless steel sintering felt can effectively make up the metal net ease plugging, vulnerable weakness, and can make up for the shortage of the powder filter product, such as fragility and small flow rate, It has the characteristics of temperature and pressure resistance that ordinary filter paper and filter cloth cannot match. Therefore, stainless steel sintered felt is an ideal filter material for high temperature, corrosion and high precision.

Features of stainless steel sintered fiber felt

High temperature and corrosion resistance. Can be used in 480 ℃ environment medium for a long time.

Easy to process, shape and weld.

High dirt holding capacity.

High porosity and excellent permeability.

High stain resistance capacity.

Long replacement cycle;

Little pressure loss and large flow.

Can be welded and machined because of its large filter area.

Easy to clean and can be used for a longer time.

Can produce reinforced, thickened, protected and other specifications according to user's requirement.

Application Fields

Polymer filtration and polyester melt purification.

Filtration of refining process, pre-filtration of ultrafilter.

Electronic high temperature gas dust removal.

Liquid purification in pharmaceutical, petroleum, biology and beverage industries.

Vacuum pump protection filter, filter membrane support, catalyst carrier.

Airbags of cars and fuel filtration of aircraft and ships.

Hydraulic system filtration.

Specifications

Item: stainless steel sintered fiber felt.

Standard Materials: 316L stainless steel fiber.

Filter rating: 99%.

Standard Length: 1200mm.

Standard Width: 1000mm.

Thickness: 0.3–0.68 mm.

Porosity: 75% – 85%.

standard size : 1000x500 1000x600 1000x1000 1200x1000

The dimensions in the above range can be customized according to user requirements.

| product specification | Filter Precision (μm) | Bubbling point pressure (pa) | Air permeabilityL/(min,dm2,kpa) | porosity(%) | containment capacity(mg/c㎡) | Thickness(mm) | fracture strength(Mpa) |

| basic value | basic value | basic value | basic value | basic value | basic value | ||

| ADZB-5 | 5 | 6800 | 47 | 75 | 5 | 0.3 | 32 |

| ADZB-7 | 7 | 5200 | 63 | 76 | 6.5 | 0.3 | 36 |

| ADZB-10 | 10 | 3700 | 105 | 75 | 7.8 | 0.37 | 32 |

| ADZB-15 | 15 | 2450 | 205 | 79 | 8.6 | 0.4 | 23 |

| ADZB-20 | 20 | 1900 | 280 | 80 | 15.5 | 0.48 | 23 |

| ADZB-25 | 25 | 1550 | 355 | 80 | 19 | 0.62 | 20 |

| ADZB-30 | 30 | 1200 | 520 | 80 | 26 | 0.63 | 23 |

| ADZB-40 | 40 | 950 | 670 | 78 | 29 | 0.68 | 26 |

| ADZB-60 | 60 | 630 | 1300 | 85 | 36 | 0.62 | 28 |

| Deviation of 10% | Deviation of 10% | Deviation of 10% | Deviation of 10% | Deviation of 10% | Deviation of 10% |

Case

We have a client in green energy industry. In his company, it needs this felt for electrolysis purpose. He ordered 1 pc of 70% porosity, 0.4mm thick felt. After applied in their system,The felt works very well. We wish our clients business grow and will repeat business with us in future.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português