According to the type of membrane element, it can be divided into homogeneous membrane, non-paired membrane and composite membrane.

According to the characteristics of membrane elements, it can be divided into low pressure membrane, ultra-low pressure membrane, extremely ultra-low pressure membrane, low energy consumption membrane, ultra-low energy consumption membrane, high desalination rate membrane, ultra-high desalination membrane, high boron removal membrane, high flux membrane, anti- fouling membrane, etc.

According to the use of reverse osmosis membrane, it can also be divided into tap water membrane, brackish water membrane, seawater desalination membrane, semiconductor grade membrane, concentration separation membrane, thermal disinfection membrane, etc.

According to its raw materials, it can also be divided into cellulose acetate, polyamide, and composite membrane.

According to the size of the membrane element, it can be divided into small reverse osmosis membrane, 4040 membrane and 8040 membrane.

According to the structure, it can be divided into inorganic membrane, organic membrane and disc tube type.

Application

Desalination of seawater and brackish water to produce domestic water, softening of hard water to produce boiler water, and production of high-purity water. In recent years, the application of reverse osmosis technology in household water dispensers and direct drinking water supply systems has demonstrated its superiority.

In the pharmaceutical and food industries, it is used to concentrate medicinal liquids, fruit juices, coffee infusions, etc.

In printing and dyeing, food, papermaking and other industries, it is used to treat sewage, and to recycle useful substances in waste industries.

Preparation, purification and separation of certain products in chemical industry, metallurgy and pharmacy.

Major equipment

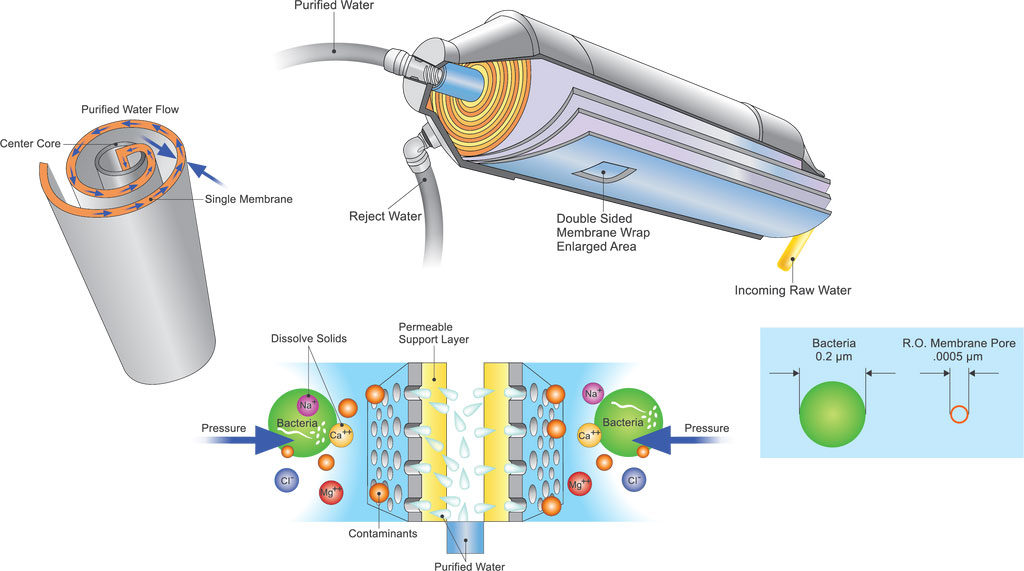

The basic equipment of reverse osmosis operation includes pretreatment filter, high pressure pump, membrane module. The membrane module is the main equipment of reverse osmosis operation.

Operating procedures

The reverse osmosis process includes two parts: pretreatment and membrane separation. Pretreatment methods include physical methods (such as precipitation, filtration, adsorption, etc.), chemical methods (such as oxidation, reduction, pH adjustment, etc.) and photochemical methods.

Common processes have several forms such as one-level, one-level multi-stage, multi-level, and circulation.

How to select the type of reverse osmosis membrane according to the water quality

1. Select the type of membrane according to the water quality of the membrane:

Influent TDS≤1000ppm can choose ultra-low pressure membrane element for influent

3000ppm≥TDS≥1000ppm can choose anti-pollution membrane element for water inlet

Brackish water desalination membrane elements can be selected for TDS≥3000ppm

Influent TDS≥5000PPM can choose seawater desalination membrane element

2. Select membrane elements according to water production (consider choosing large membrane or small membrane):

General situation: 4040 membrane elements are mostly used for reverse osmosis equipment with water production <4T/H; 0.25 ton/hour reverse osmosis equipment, 1 4040 membrane, 2 0.5 ton/hour reverse osmosis equipment, 1 ton/hour reverse osmosis 4 root, and so on. 8040 membrane elements are mostly used in reverse osmosis equipment with water production ≥ 4T/H. 8040 membrane elements are about 1 ton/hour, and 4 8040 membrane elements are selected for reverse osmosis equipment of 4 tons/hour.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português