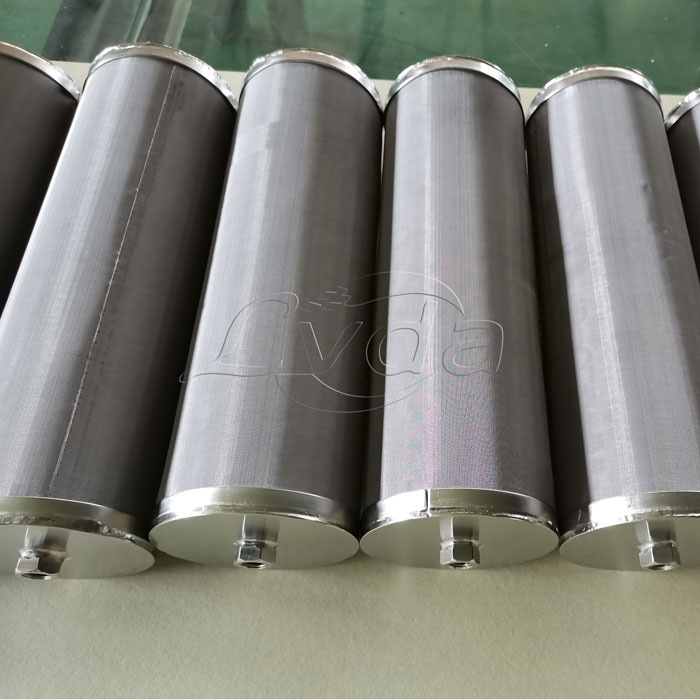

Sintered filter elements are part of the filter unit and the core of the filter. Generally speaking, the sintered mesh filter element is a new type of filter material with good performance and filtration effect, which is processed by stainless steel as a woven mesh filter material, and can be processed into a desired shape as needed. In the sintered mesh filter element, its pores are criss-crossed, have good anti-high temperature and anti-cold and anti-heat effects, have good anti-corrosion effect, and therefore can be used in an acid-base environment. The sintered mesh filter also has strong toughness, which can be easily welded and loaded and unloaded. The aperture is stable and evenly distributed. It also has good filtering precision and efficiency under the condition of ensuring stable filtration performance, and its flow rate per unit area is large. Moreover, the service life is long, the cost is effectively saved, and the anti-cleaning regeneration performance is provided, and the repeated use can be performed without deformation, thereby further improving the cost performance of the filtration.

Main connection method

⑴Standard interface (such as 222, 220, 226);

⑵Fast interface connection;

⑶Threaded connection;

⑷Flange connection;

⑸Tie rod connection;

⑹Special custom connection.

Product application areas

Sintered mesh filter cartridges are widely used in pharmaceuticals, fluidized beds, liquid and gas filtration, chemical processing, chemical fiber filtration, food and beverage, oil and gas filtration, polyester and water treatment industries.

Specification

⑴Material:304304L, 316316L, 310S, 2507 punching net, stretch net, weave network, stainless steel welded wire mesh, sintered net, etc.

⑵Filter rating: from 1 mircon to 250 mircon.

⑶Layers:Single layer, multi layer.

⑷Style:Binaural type, basket type, flange type, basket type filter cartridge, thread interface style etc.

case

We have a client from India. he is in pharmaceutical industry. he uses our filter element to process the raw material. after consulting with our engineer, he ordered 30 pcs. last month, he received the filter and installed in the system. it proves very well. we hope to help grow their business in the future.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português