Product Details

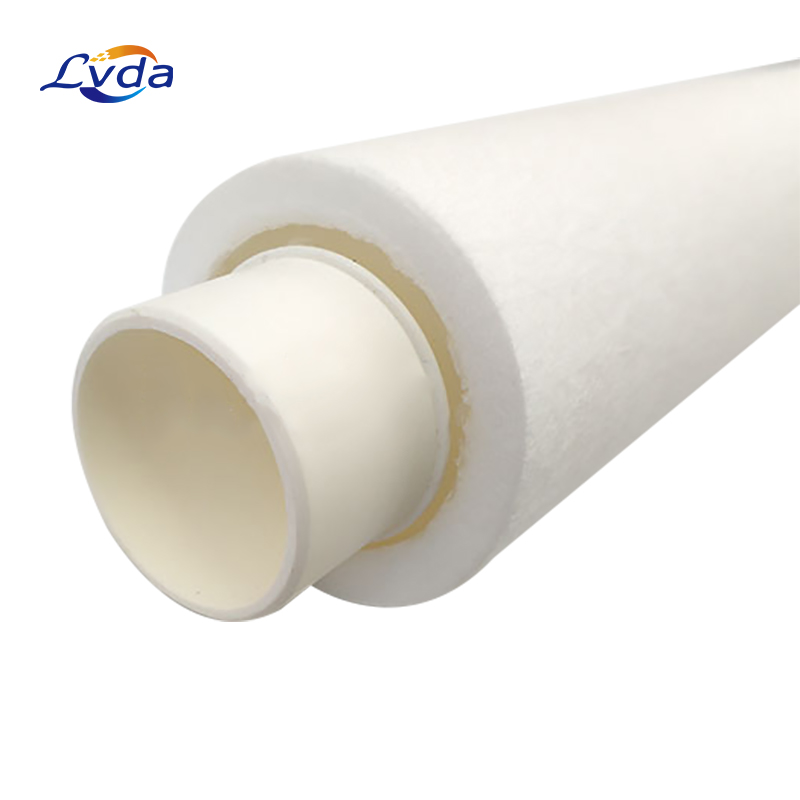

The stator cooling water filter element SL-12/50 is installed in the filter. The liquid flows into the filter from the inlet. Through the vertically arranged melt blown filter element, the impurities in the fluid are adsorbed on the surface of the filter element. Clean liquid flows out of the space inside the filter element, and then flows into the system from the outlet of the filter to ensure the cleanliness of the system fluid.

The cooling water stator cooling water filter element SL-12/50 is a large flow filter element dedicated for power plants, which can effectively filter out various impurities such as fine particles in the water to ensure the good operation of the equipment. The size of the condensate filter element can be customized according to the needs of the on-site environment.

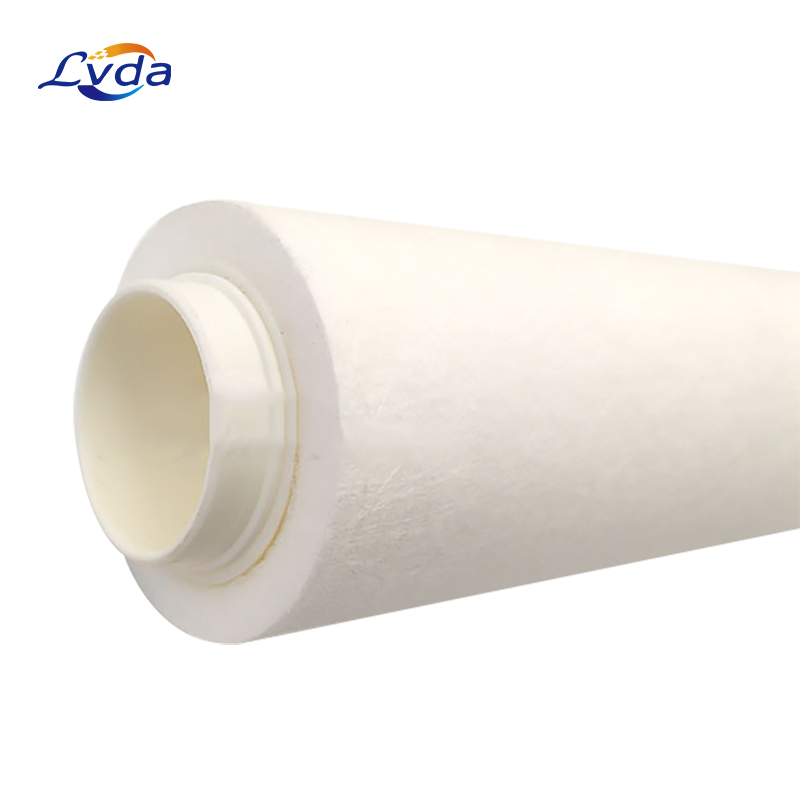

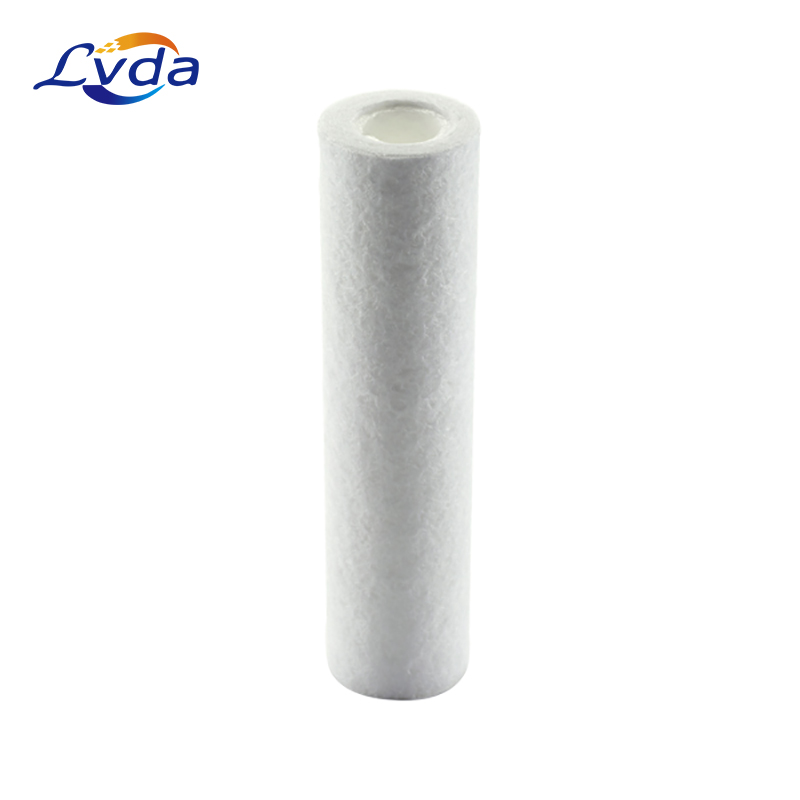

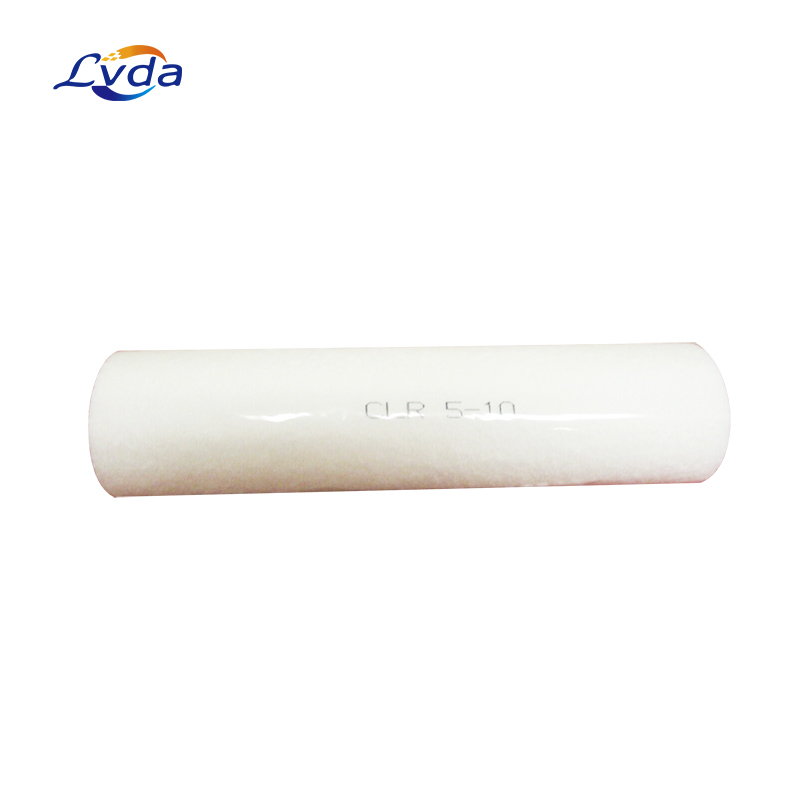

The stator cooling water filter element SL-12/50 of the generator unit is mainly used for filtering the condensed water of the cooling tower of the power plant. Because of its high sewage holding capacity and filtering accuracy, it is recognized by customers of power plants and steel plants. The stator cooling water filter element is a special filter element for power plants and can also be used for water filtering in other industries. The sI-12/50 filter element belongs to the non-standard power plant cooling water filter element. Both ends of the filter element are equipped with our special connectors, which can be conveniently installed in the corresponding filtering device. The length of the filter element is about 865mm. The main material of the filter element is pp polypropylene which is processed by high-temperature hot melting. It has high resistance to high temperature and low temperature and is not easy to be corroded. The filtering accuracy is very stable during long-term use, and it can guarantee users for 12 months.

SL-12/50 stator cooling water filter element is widely used in the power and metallurgical industries. At present, LVDA can customize and produce stator cooling water filter elements of various models and specifications for users. Our company has a modern water filter element production workshop and testing technology. Previously, some manufacturers used glue to bond the connector of stator cooling water filter element, which is very easy to fall off during use. Later, our company developed and produced more perfect products through our technology, The connection of stator cooling water filter element produced by our company is made by hot melt bonding technology, which makes the connection more reliable and not easy to fall off. The improvement of this technology has also promoted our stator cooling water filter element to open the market rapidly in the domestic market.

Product features

1.High filtering efficiency and precision, uniform pore density of filter element, and filtering efficiency of more than 99%.

2.The filter resistance is small, the filter flow is large, the dirt holding capacity is large, and the service life is long. During the production process, the fiber diameter and gap of the product are adjustable. The inner layer of the filter element is small and the outer layer is large, which increases the flow and dirt holding capacity. The filter element is not easy to block, and extends the service life.

3.High self cleanliness, no pollution to water quality, acid and alkali resistance, organic solvent resistance and corrosion.

4.High strength, the filter element will not deform when the water pressure difference between the inlet and outlet of the filter exceeds 0.4Mpa, and the filter efficiency will not decrease when the temperature exceeds 90 ° C.

5.This product has extremely high hydrophilicity after treatment and modification of polypropylene, and can absorb ten times the weight of water, so it can be used for oil-water separation.

Product parameters

Initial differential pressure: | 0.02MPa |

Replacement pressure drop: | 0.24MPa |

High temperature: | within 82 ° C |

Accuracy level: | 0.5um - 10um |

Outer diameter: | 23 mm |

Length: | 865mm |

Filtering method: | external pressure |

Place of use: | mine water concentrated brine device |

Filtering precision: | 0.5-50 |

Filter material: | polypropylene |

Nominal pressure: | 0.6Mpa |

Product application

1.Hotels, Garment Shops,

2.Building Material Shops,

3.Manufacturing Plant,

4.Machinery Repair Shops,

5.Food & Beverage Factory,

6.Farms,

7.Restaurant,

8.Home Use,

9.Retail, Food Shop,

10.Printing Shops,

11.Construction works ,

12.Energy & Mining,

13.Food & Beverage Shops,

14.Advertising Company

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português