Product Details

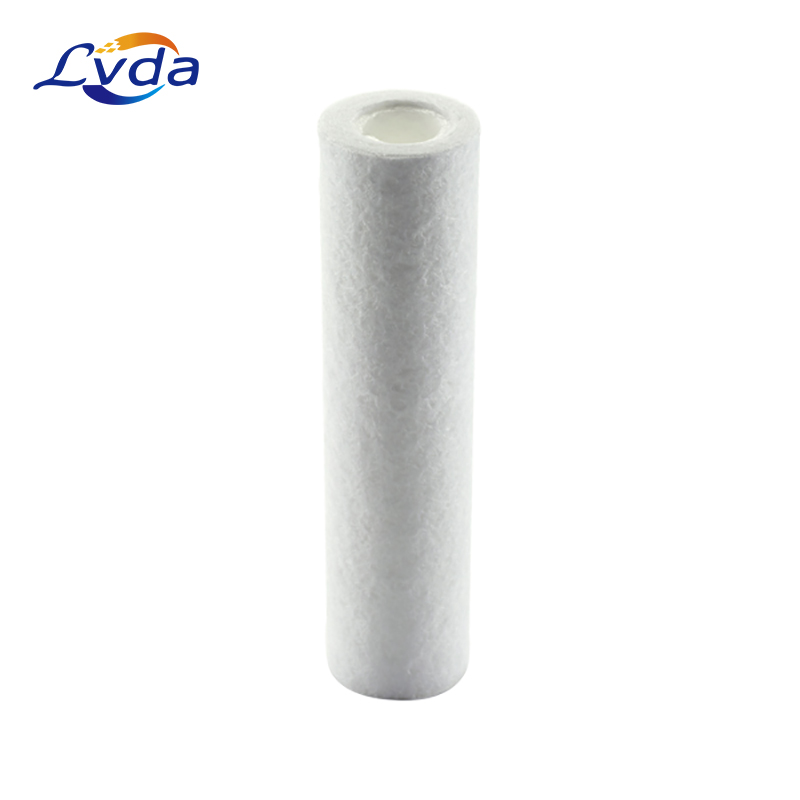

PP meltblown filter element is a tubular filter element made of non-toxic and

odorless polypropylene particles after heating, melting, spinning, pulling, and

receiving forming. It is not only used in water purification in large

quantities. Filtration of strong acids, alkalis and organic solvents, this

filter element is a fixed-pore depth filter element with ultra-fine

polypropylene fiber filter material as the filter medium, and the filter

material meets the relevant FDA requirements.

Application

Electric power, petrochemical, chemical, food and beverage,

automobile, industry, metallurgy, papermaking, medicine, microelectronics,

environmental protection water treatment and other industries.

Feature

Step-by-step filtering; sparse outside and inner dense design.

Internal thread structure is adopted; the compression resistance is enhanced;

the adsorption and compression resistance are greatly improved.

It is made of PP polypropylene material, which is healthy, safe and

non-toxic, and will not cause secondary water pollution.

Working Principle

It mainly uses activated carbon organic flocs with high carbon content, large

molecular weight and large specific surface area to physically adsorb impurities

in water to meet the water quality requirements. When the water flows through

the pores of activated carbon, various suspended particles, organic matter, etc.

under the action of van der Waals force It is adsorbed in the pores of the

activated carbon; at the same time, the chlorine (hypochlorous acid) adsorbed on

the surface of the activated carbon undergoes a chemical reaction on the surface

of the activated carbon and is reduced to chloride ions, thereby effectively

removing the chlorine and ensuring that the residual chlorine in the effluent is

less than 0.1ppm, satisfying Operating conditions of RO membranes. With the

passage of time, the retentate in the pores of the activated carbon and between

the particles gradually increases, so that the pressure difference between the

front and rear of the filter increases until it fails.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português