Product Details

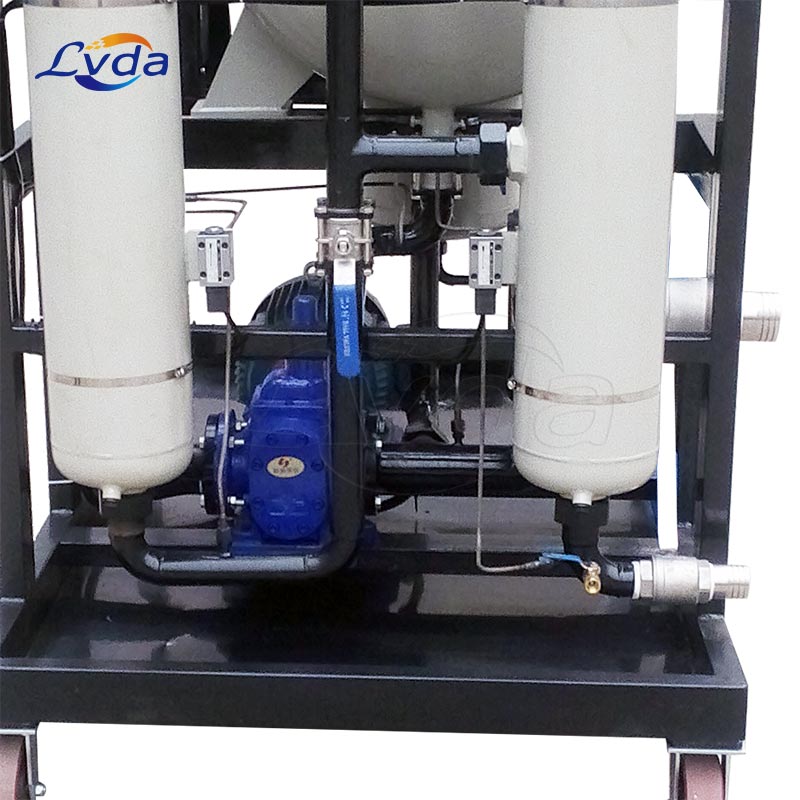

Gasoline coalescence separation oil purifier

Our gasoline coalescence separation oil purifier integrates two functions of precision filtration and high-efficiency dehydration. It uses advanced "coalescence separation" technology for dehydration. It has high dehydration efficiency and strong capacity. It is especially suitable for separating a large amount of water in oil. It has a vacuum method and a centrifugal method. Incomparable advantages can break all the oil-water emulsified structure in the medium. Through the filtration of the particle filtration system, the cleanliness of the medium can be stably controlled in the state required by the system to ensure the cleanliness of the oil. Do not change the physical and chemical properties of the oil, extend the life of the oil. Low energy consumption and low operating costs. The system configuration is excellent, the continuous working performance is strong, suitable for online operation.

Coalescence system: The coalescing system consists of a set of coalescing filter elements. The coalescing filter element uses a unique polar molecular structure. The free water and emulsified water in the oil are coalesced into larger water droplets after passing through the filter element and then rely on the action of gravity Settling into the water storage tank.

Separation system: The separation filter element of the separation system is made of a special hydrophobic material. When the oil passes through the filter element, the water beads are blocked on the outer surface of the filter element and coalesce with each other until they sink into the water storage tank due to gravity.

Drainage system: The separated water is stored in the water storage tank. When the interface height reaches the set value, the valve is opened to discharge the water until it reaches the lower liquid level, the valve is closed, and the water is stopped for drainage. According to the user's requirements, an oil-water interface instrument can also be installed so that the oil-water interface can be measured. When the set upper limit value is reached, the solenoid valve at the bottom of the water storage tank opens. The accumulated water is discharged through the drainage port to realize automatic drainage, and it is truly unattended.

Product parameters

| Model |

A0P-D25 |

AOP-D50 |

A0P-D100 |

AOP-D150 |

A0P-D200 |

AOP-D400 |

| Rated flow(L/min) |

25 |

50 |

100 |

150 |

200 |

400

|

| Rated pressure(MPa) |

0.6 |

| Initial pressure loss (Mpa) |

≤0.1 |

| Filtered water content |

≤100 |

| Coarse filtration( μ m) |

100 |

| Grade 1 filter rating( μ m) |

10、20 |

Grade 2 filter rating( μ m) |

3、5 |

| Pressure differentials |

0.2Mpa |

| Working temperature(°C) |

25- 80 |

| Recommended viscosity(cSt) |

10-120 |

| Voltage(V) |

AC 380V(Three-phase)、50Hz |

| Motor power(kw) |

0.75 |

1.1 |

2.2 |

4 |

5.5 |

13

|

| Weight(kg) |

150 |

200 |

300 |

520 |

860 |

2860

|

| Dimensions(mm) |

1200x 800x1250 |

1350 x800x1400 |

1740x 980x1450 |

1800x1000x1540 |

1840x1050x1780 |

3180x 1600x2000 |

Note: *-is filter's rating,such as 03 is 3 microns.

**-is the suitable medium,Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

***-explosion-proof type: add F before type, Omission: normal type

Product features:

*This type of oil purifier adopts a special oil-water separation filter, which does not require heating, which completely guarantees that the additives in the oil will not crack or deteriorate, and the quality of the oil can be guaranteed after dehydration.

*The operation is simple, with automatic water delivery device, which can automatically run and release water online without any need for personnel on duty.

*This type of equipment has standard type and explosion-proof type.

*Working principle: The unqualified oil first enters the primary filtration, and the large particles of impurities are retained. The oil that removes the large particles of impurities is then transported to the fine filter by the oil pump. After the small impurities are removed in the fine filter, it continues to enter the coalescence In the separator, the principle of molecular separation technology is used to analyze the oil under pressure, eliminate the intermolecular binding force, dissolve water, free water in the oil, quickly break the oil film and separate the oil molecules and separate out; so far, the dehydration and removal of impurities are completed. , so as to achieve the required moisture and cleanliness requirements.

*This machine is equipped with perfect protection device. Through the implementation of the original machine, the temperature, pressure, vacuum degree, power failure, etc. are fully protected, which can effectively prevent accidents and ensure the normal operation of the equipment.

*The automatic control and protection system consists of sensors, motors, and protection components. After the working pressure reaches the set point, the whole machine will alarm and stop working to prevent accidents.

Product applications

Steam turbine oil and transformer purification.

Water removal and impurity filtering of hydraulic lubrication system oil.

Integrate hydraulic lubrication system to improve the cleanliness of the system.

Is widely used in: Mechanical processing, metallurgical industry, petrochemical industry, cement plant, electric power industry, iron and steel industry, paper industry, textile industry, purification of turbine oil and transformer oil,ordinary diesel, gasoline, kerosene, etc.;

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português