Product Details

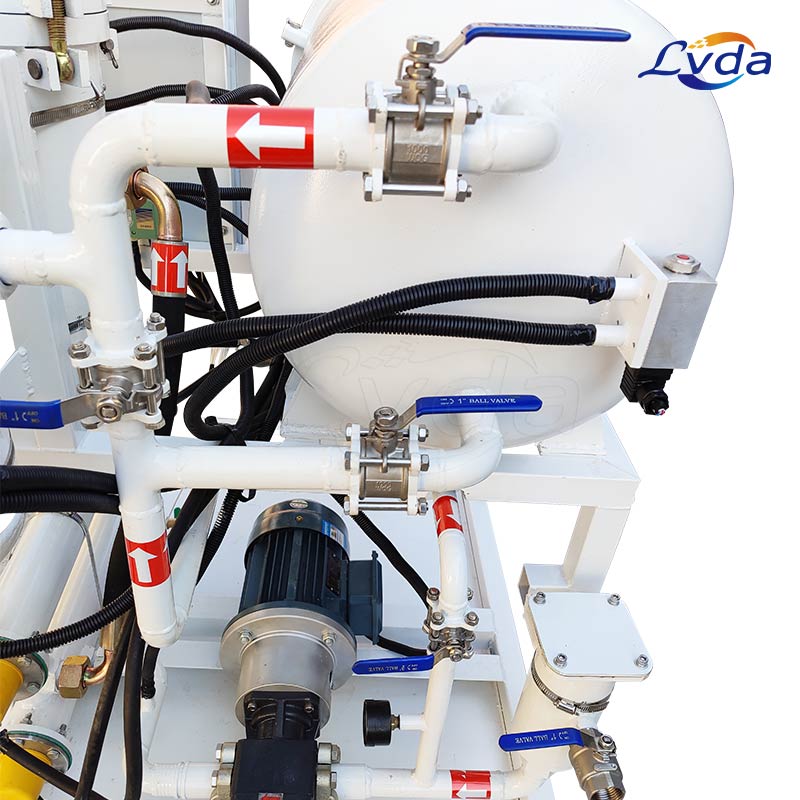

Diesel oil filtration coalescing separating oil purifier

Our diesel oil filtration coalescing separating oil purifier employs advanced coalescing and separating materials as the filtering medium, which integrates emulsification and precision filtration. Combined with a special oil-water separation device, it can effectively separate the water in the oil, the dehydration efficiency is extremely high. It can remove impurities of diesel. This machine does not need to heat and evacuate during operation, it is low energy consumption and low operating cost. The trolley structure is adopted, which is light and flexible and easy to use.

Product parameters

| Model | A0P-D25 | AOP-D50 | A0P-D100 | AOP-D150 | A0P-D200 | AOP-D400 |

| Rated flow(L/min) | 25 | 50 | 100 | 150 | 200 | 400

|

| Rated pressure(MPa) | 0.6 |

| Initial pressure loss (Mpa) | ≤0.1 |

| Filtered water content | ≤100 |

| Coarse filtration( μ m) |

100 |

| Grade 1 filter rating( μ m) | 10、20 |

Grade 2 filter rating( μ m) | 3、5 |

| Pressure differentials | 0.2Mpa |

| Working temperature(°C) | 25- 80 |

| Recommended viscosity(cSt) | 10-120 |

| Voltage(V) | AC 380V(Three-phase)、50Hz |

| Motor power(kw) | 0.75 | 1.1 | 2.2 | 4 | 5.5 | 13

|

| Weight(kg) | 150 | 200 | 300 | 520 | 860 | 2860

|

| Dimensions(mm) | 1200x 800x1250 | 1350 x800x1400 | 1740x 980x1450 | 1800x1000x1540 | 1840x1050x1780 | 3180x 1600x2000 |

Note: *-is filter's rating,such as 03 is 3 microns.

**-is the suitable medium,Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

***-explosion-proof type: add F before type, Omission: normal type

Product features

- No heating, no vacuum negative pressure required, low power and low running cost.

- It integrates two functions of precision filtration and efficient dehydration.

- Continuous large flow treatment, strong purification capacity and high dehydration efficiency.

- Pure physical purification, does not change the physical and chemical properties of the oil, and prolongs the service life of the oil.

Product applications

1. Metallurgy: used for the filtration of the hydraulic system of rolling mills and continuous casting machines and the filtration of various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in the process of oil refining and chemical production, and particle removal and filtration of oilfield well injection water and natural gas.

3. Textile: Purification and uniform filtration of polyester melt in the process of drawing, protection and filtration of air compressors, and degreasing and dehydration of compressed gas.

4. Electronics and pharmaceuticals: pre-treatment and filtration of reverse osmosis water and deionized water, pre-treatment and filtration of cleaning solution and glucose.

5. Electricity and nuclear power: gas turbine, boiler lubrication system, speed control system, bypass control system oil purification, water supply pump, fan and dust removal system purification.

6. Mechanical processing equipment: Papermaking machinery, mining machinery, injection molding machine and large precision machinery lubrication system and compressed air purification, tobacco processing equipment and spraying equipment dust recovery and filtration.

7. Railway internal combustion engine and generator: filtration of lubricating oil and diesel oil.

8. Automobile engines and construction machinery: various hydraulic oil filters, diesel filters, and water filters for internal combustion engine air filters, fuel filters, construction machinery, ships, and trucks.

9. Various lifting and handling operations: from construction machinery such as hoisting and loading to special vehicles such as fire fighting, maintenance and handling, ship cranes, windlasses, blast furnaces, steel-making equipment, ship locks, opening and closing devices for ship doors, Elevating orchestra pits and elevating stages of theaters, various automatic conveying lines, etc.

10. Various operating devices that require force such as pushing, squeezing, pressing, shearing, cutting, and excavation: hydraulic presses, die-casting, forming, rolling, calendering, stretching, and shearing equipment of metal materials, plastic injection molding machines, plastic Chemical machinery such as extruders, tractors, harvesters and other agricultural and forestry machinery for felling and mining, excavation equipment for tunnels, mines and ground, steering gears for various ships, etc.

11. High-response, high-precision control: tracking and driving of artillery, stabilization of turrets, anti-swing of ships, attitude control of aircraft and missiles, high-precision positioning system of processing machine tools, driving and control of industrial robots, metal Sheet pressing, thickness control of leather slices, speed control of power station generators, high-performance vibration tables and testing machines, large-scale motion simulators and entertainment facilities with multiple degrees of freedom, etc.

12. Automatic manipulation and control of various work program combinations: combined machine tools, automatic machining lines, etc.

13. Special workplace: operating equipment in special environments such as underground, underwater, and explosion-proof.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português