Product Details

Fuel filtration & coalescer skids

The harmful effects of moisture and particulate contamination in fuel oil have been well documented. Oil filtration systems has combined the latest innovations in coalescer technology and pleated microglass filter media in one system to achieve optimal fluid cleanliness in fuel oils.

Utilizing high efficiency coalescer/separator filter elements, these systems are designed to quickly remove large amounts of free water from diesel fuel or other fuel oils, achieving overall water content as low as 7 PPM. At the same time, the high efficiency pleated microglass filter elements are capable of achieving very low particle counts as low as an ISO 15/13/10 Cleanliness Level.

This equipment will ensure that #2 diesel fuel meets or exceeds all new stringent fuel oil cleanliness specifications set by many OEMs.

Product parameters

| Model | A0P-D25 | AOP-D50 | A0P-D100 | AOP-D150 | A0P-D200 | AOP-D400 |

| Rated flow(L/min) | 25 | 50 | 100 | 150 | 200 | 400

|

| Rated pressure(MPa) | 0.6 |

| Initial pressure loss (Mpa) | ≤0.1 |

| Filtered water content | ≤100 |

| Coarse filtration( μ m) |

100 |

| Grade 1 filter rating( μ m) | 10、20 |

Grade 2 filter rating( μ m) | 3、5 |

| Pressure differentials | 0.2Mpa |

| Working temperature(°C) | 25- 80 |

| Recommended viscosity(cSt) | 10-120 |

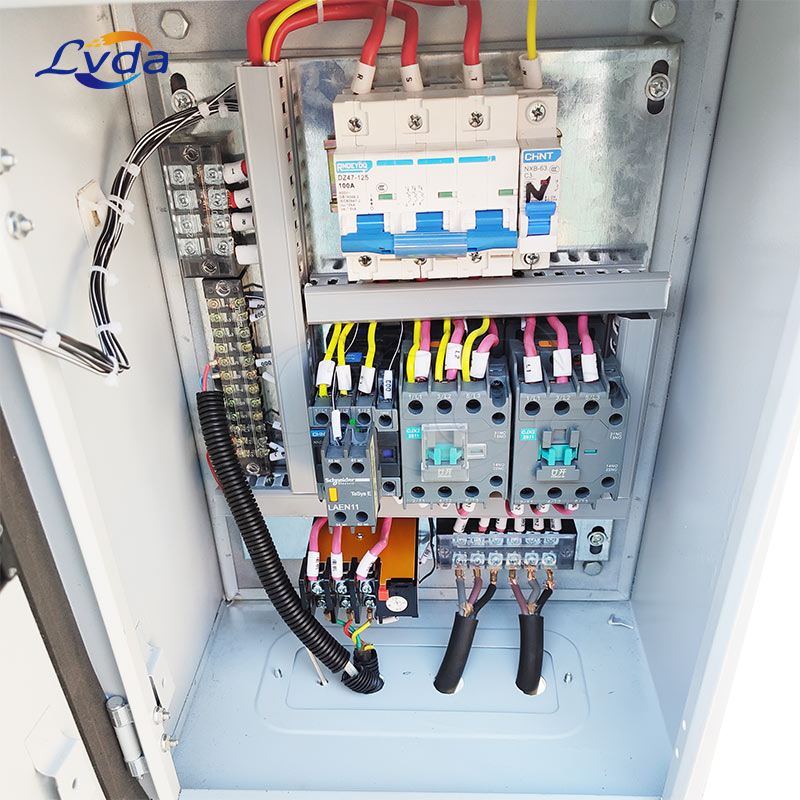

| Voltage(V) | AC 380V(Three-phase)、50Hz |

| Motor power(kw) | 0.75 | 1.1 | 2.2 | 4 | 5.5 | 13

|

| Weight(kg) | 150 | 200 | 300 | 520 | 860 | 2860

|

| Dimensions(mm) | 1200x 800x1250 | 1350 x800x1400 | 1740x 980x1450 | 1800x1000x1540 | 1840x1050x1780 | 3180x 1600x2000 |

Note: *-is filter's rating,such as 03 is 3 microns.

**-is the suitable medium,Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

***-explosion-proof type: add F before type, Omission: normal type

Product features

-All vessels built to ASME Code Design

-Differential pressure gauges give positive indication when filter elements are plugged and need to be changed

-Upstream & downstream fuel sample ports

-Duplex configurations which enable an operator to change out plugged filters without interrupting the flow of fuel through filters

-Automatic water drain from coalescer vessels (electric or mechanical)

-Electric differential pressure switches for remote monitoring

-Bag filter housings loaded with polyester felt bags to act as pre-filters, cost effectively removing large concentrations of bulk particulate contamination and significantly extending the life of high efficiency pleated microglass and coalescer filter elements downstream

-Stainless steel materials of construction

Product applications

#2 Diesel fuel for use in turbines(eg. General Electric TM2500)

High sulphur and low sulphur #2

Diesel fuel for use in CAT? haul trucks and other large mobile equipment

Medium unleaded gasoline (MUM)

Light fuel oil (LFO)

Naptha

Alcohols

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português