Product Details

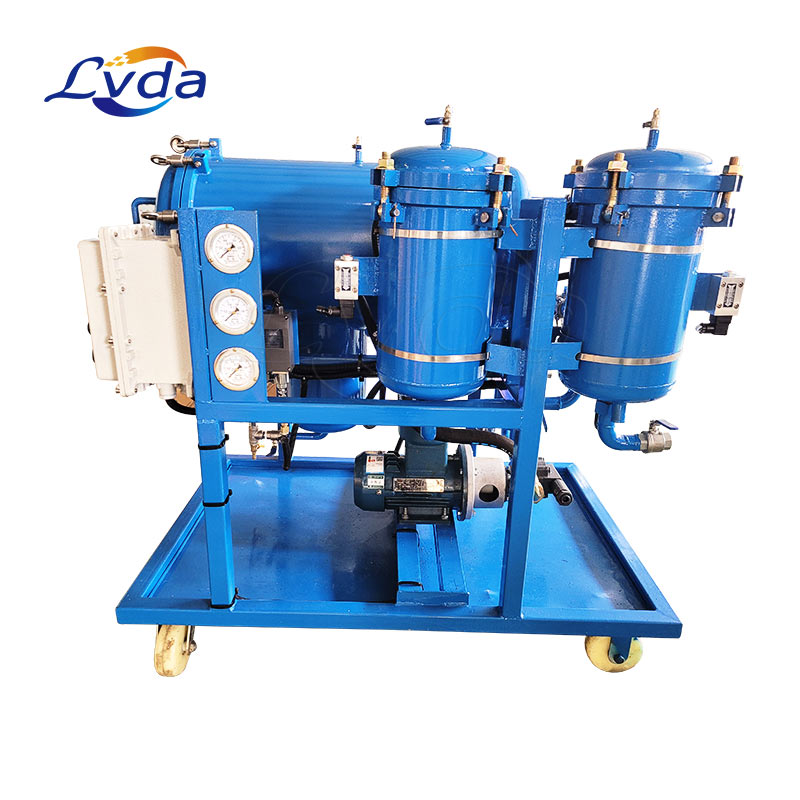

Engine oil coalescing dehydration device

The coalescing oil filter integrates two functions of precision filtration and high-efficiency dehydration. It applies advanced "coalescence separation" technology for dehydration, with high dehydration efficiency and strong capacity, especially for the separation of a large amount of water in the oil. The incomparable advantages of the centrifugal method can remove all the oil-water emulsification structure in the medium; through the filtration of the particle filtration system, the cleanliness of the medium can be stably controlled in the state required by the system to ensure the cleanliness of the oil; no change The physical and chemical properties of the oil prolong the service life of the oil; the operating cost is low; the system configuration is excellent, the continuous working performance is strong, and it is suitable for online operation.

Product parameters

| Model | A0P-D25 | AOP-D50 | A0P-D100 | AOP-D150 | A0P-D200 | AOP-D400 |

| Rated flow(L/min) | 25 | 50 | 100 | 150 | 200 | 400

|

| Rated pressure(MPa) | 0.6 |

| Initial pressure loss (Mpa) | ≤0.1 |

| Filtered water content | ≤100 |

| Coarse filtration( μ m) |

100 |

| Grade 1 filter rating( μ m) | 10、20 |

Grade 2 filter rating( μ m) | 3、5 |

| Pressure differentials | 0.2Mpa |

| Working temperature(°C) | 25- 80 |

| Recommended viscosity(cSt) | 10-120 |

| Voltage(V) | AC 380V(Three-phase)、50Hz |

| Motor power(kw) | 0.75 | 1.1 | 2.2 | 4 | 5.5 | 13

|

| Weight(kg) | 150 | 200 | 300 | 520 | 860 | 2860

|

| Dimensions(mm) | 1200x 800x1250 | 1350 x800x1400 | 1740x 980x1450 | 1800x1000x1540 | 1840x1050x1780 | 3180x 1600x2000 |

Note: *-is filter's rating,such as 03 is 3 microns.

**-is the suitable medium,Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

***-explosion-proof type: add F before type, Omission: normal type

Product features:

1) Remove all the oil-water emulsification structure in the oil.

2) The free water in the oil is removed, and the water content after treatment is less than 100PPM.

3) Filter the solid particles in the oil, and the cleanliness reaches NAS6 level or higher.

4) It integrates two functions of precision filtration and dehydration.

5) It has high filtration precision, large dirt holding capacity, long service life of filter element and high dehydration efficiency.

6) No heating, vacuuming and high-speed centrifugation, low energy consumption and low cost of use.

7) It will not change the physical and chemical properties of the oil and prolong the service life of the oil.

8) The equipment runs online, automatically controlled, and unattended.

9) Continuous processing of large flow.

Product applications

Metallurgical industry, petrochemical industry, electronic industry, thermal power and nuclear power, mechanical processing, pharmaceutical industry, textile industry, railway internal combustion engine, etc.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português