Product Details

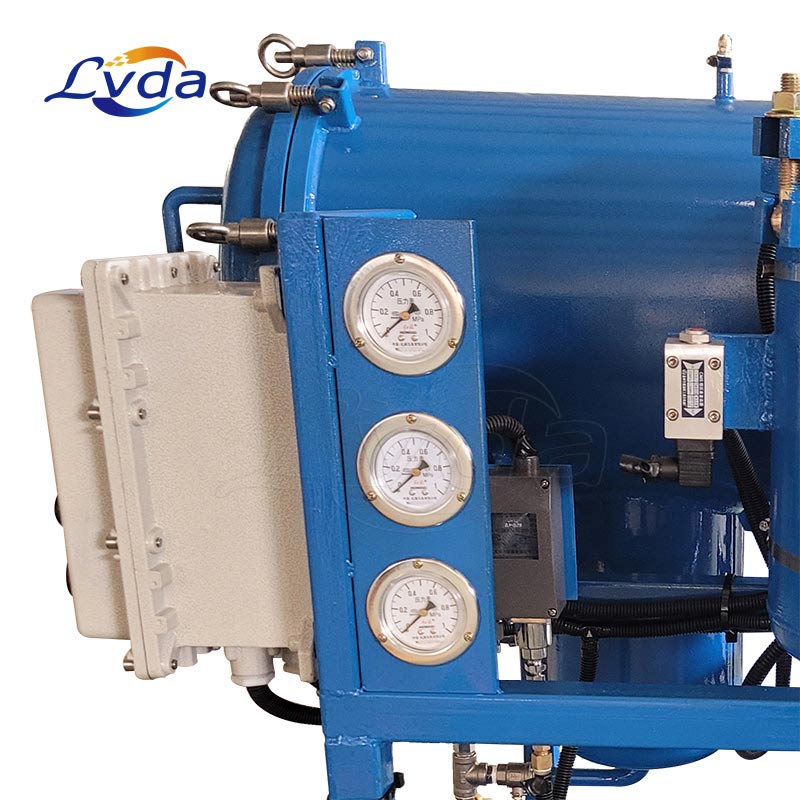

Waste engine oil coalescing dehydration purifier

The working process and technical principle of our waste engine oil coalescing dehydration purifier:

Different liquids have different surface tensions, and when a liquid flows through a small hole, the lower the surface tension, the faster the rate of passage. When the mixed liquid of different phases flows into the separator, it first enters the coalescing filter element. The coalescing filter element has a multi-layer filter medium, and its pore size increases layer by layer. Due to the difference in surface tension, the oil passes through the filter layer quickly, while the water is much slower; and because the coalescing filter element is made of hydrophilic materials, tiny water droplets are adsorbed on the surface of the filter layer, causing the water droplets to coalesce. Under the action of kinetic energy, small droplets compete to pass through the openings, gradually converge into large droplets, and settle under the action of gravity to separate from the oil. After passing through the coalescing filter element, there are still small water droplets moving forward to the separation filter element under the action of inertia. The separation filter element is made of special hydrophobic material. When the oil passes through the separation filter element, the water droplets are blocked from the outside of the filter element, while the oil passes through the separation filter element and is discharged from the outlet.

Our Waste engine oil coalescing dehydration purifier integrates two functions:

1.precision filtration

2.high-efficiency dehydration

The waste engine oil coalescing dehydration purifier uses advanced "coalescence separation" technology for dewatering, with high dehydration efficiency and strong capacity, especially for the separation of huge amount of water in the oil. It has the incomparable merits of vacuum method and centrifugal method, and can break all the oil-water emulsification structure in the medium.

Product parameters

| Model | A0P-D25 | AOP-D50 | A0P-D100 | AOP-D150 | A0P-D200 | AOP-D400 |

| Rated flow(L/min) | 25 | 50 | 100 | 150 | 200 | 400

|

| Rated pressure(MPa) | 0.6 |

| Initial pressure loss (Mpa) | ≤0.1 |

| Filtered water content | ≤100 |

| Coarse filtration( μ m) |

100 |

| Grade 1 filter rating( μ m) | 10、20 |

Grade 2 filter rating( μ m) | 3、5 |

| Pressure differentials | 0.2Mpa |

| Working temperature(°C) | 25- 80 |

| Recommended viscosity(cSt) | 10-120 |

| Voltage(V) | AC 380V(Three-phase)、50Hz |

| Motor power(kw) | 0.75 | 1.1 | 2.2 | 4 | 5.5 | 13

|

| Weight(kg) | 150 | 200 | 300 | 520 | 860 | 2860

|

| Dimensions(mm) | 1200x 800x1250 | 1350 x800x1400 | 1740x 980x1450 | 1800x1000x1540 | 1840x1050x1780 | 3180x 1600x2000 |

Note: *-is filter's rating,such as 03 is 3 microns.

**-is the suitable medium,Omission:General hydraulic oil;BH:Water - glycol , V:Phosphonate hydraulic fluid

***- the medium viscosity is too high or the oil temperature is low,need to add the heating device.

***-explosion-proof type: add F before type, Omission: normal type

Product features

*Use special oil pump to transport oil.

*Unique degassing and dehydration system to quickly separate water and gas in oil.

*Multi-stage filtration is encrypted step by step, with large dirt holding capacity, long service life of filter element, and automatic detection function of filter element pollution.

*The heating system adopts the optimized pipeline design to ensure uniform heating and stable oil temperature.

*Automatic constant temperature control system, automatic liquid level control system, automatic defoaming control system, automatic pressure protection system and sophisticated configuration ensure the high-performance operation of the equipment.

*Online oil filter, can be unattended, and the running status is displayed by indicator lights.

*Humanized design of this machine, low noise, simple operation, long maintenance interval, low energy consumption, saving operating cost.

Product applications

Mechanical processing, metallurgical industry, petrochemical industry, cement plant, electric power industry, iron and steel industry, paper industry, textile industry, purification of turbine oil and transformer oil; water removal and impurity removal of oil in hydraulic lubrication system; comprehensive access to hydraulic lubrication system Improve system cleanliness.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português