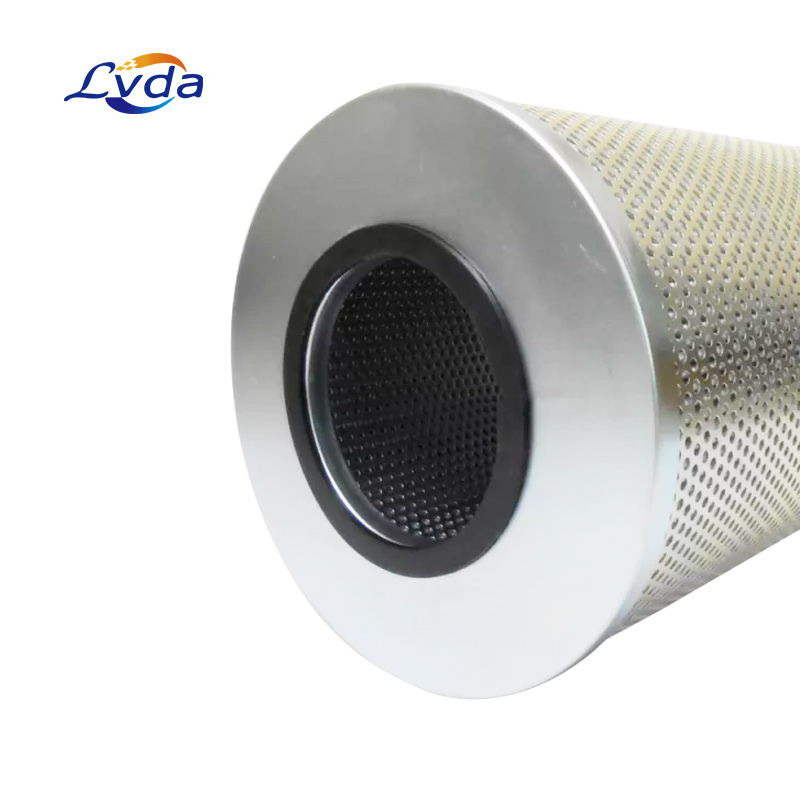

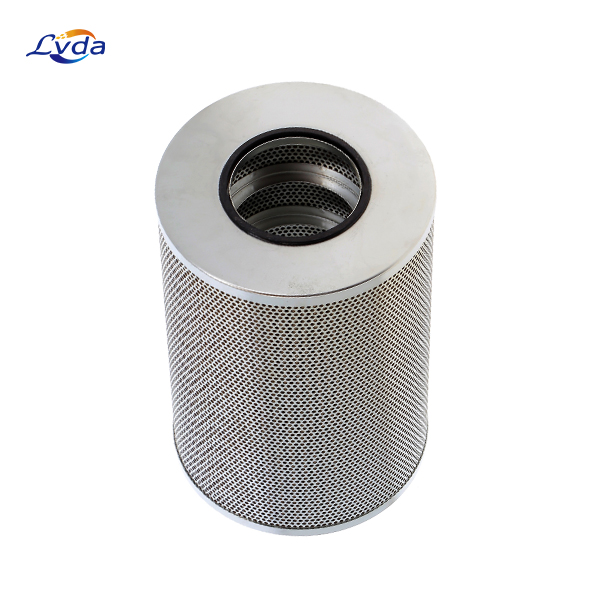

Product Details

A hydraulic filter is a component within a hydraulic system that removes damaging particulates by forcing hydraulic fluid through a porous filter element. The filter element catches contaminants and prevents them from re-entering the fluid flow and damaging other pieces of equipment further downstream. Contaminants range from dirt to water and reactive chemicals. Their size is on a scale of micrometers, meaning hydraulic filters must be properly sized to filter out even the smallest of particles.

Hydraulic filters are placed at various locations throughout a system to catch contaminants created at different points in the process. For ideal filtration, filters would be before and after the pump, in the return lines, off-line and within the reservoir. However, considerations for cost and space impact where designers choose to place filters. There are a few primary locations, which determine the types of hydraulic filters used:Return lines,Suction filters,Pressure lines, Off-lines.

Product features

1.Unique Construction – Specifically designed for transformer oil dehydration.

2.High Capacity – Process up to 5,000 gallons of oil or more with a single cartridge.

3.Efficient – Single pass water removal to less than 10 ppm total water, or better.

4.Versatile – Models available to fit most industry standard housings.

5.Safe – Will not remove oxidation inhibitors.

6.Cost Effective – Process transformer oil for less than 5¢ per gallon.

Product parameters

Model: | C6370467 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | ISO9001 |

Quality: | 100% Tested |

Working pressure: | -21~210 bar |

od_top_mm | 180.09 |

centertube | PLATED STEEL |

endcap | PLATED STEEL |

flow | OUTSIDE->IN |

Dimension(L*W*H): | 170*86*328mm |

Weight: | 2.2 kg |

Filter type | Hydraulic filter |

Material | Glass fiber |

Working temperature | -10℃~+100℃ |

Service life | 8-12 months |

Product application

1.Chemical and petrochemical industry

2.Pharmaceutical industry

3.Prefiltration of sterile filters

4.Filling machines

5.Food & beverage industry

6.Packing machines

7.Process industry

8.Industrial Manufacturing Equipment

9.Automotive

10.Electronics

11.Pharmaceuticals

12.Medical & Dental

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português