Product Details

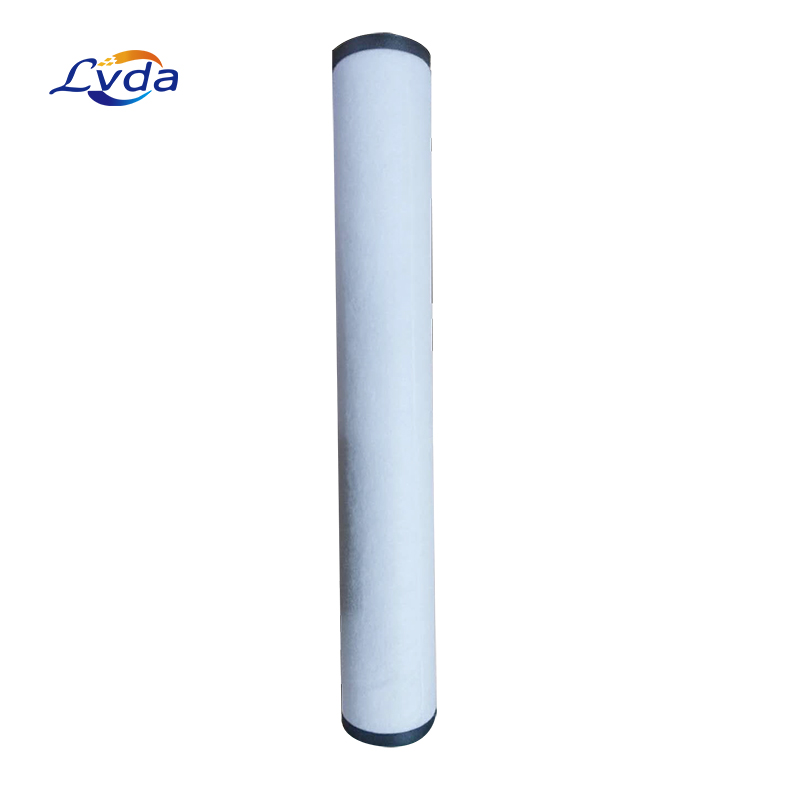

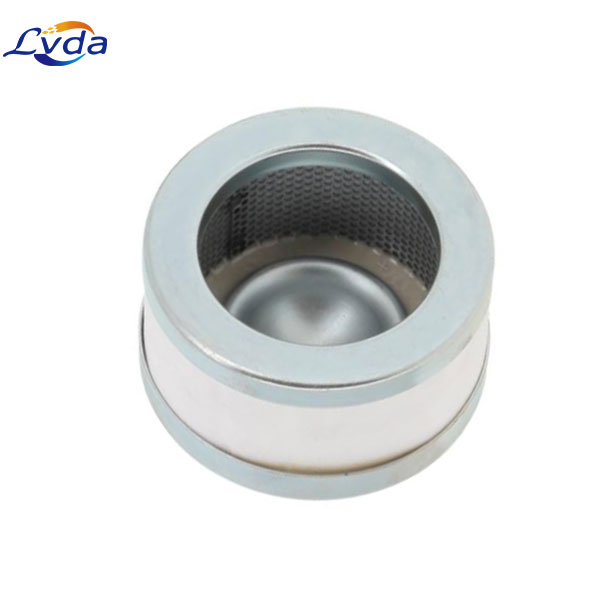

The filter element of vacuum pump is designed to maintain the efficient and normal operation of vacuum pump and extend the service life of vacuum pump. It plays a good role in protecting the vacuum pump. Generally, the vacuum pump needs three levels of filtration at the same time.

First level filtration, air inlet filtration: to intercept the solid particles in the suction gas. By intercepting the larger impurities and dust particles, the pressure of the two-level filtration at the back end is greatly reduced, the mechanical wear during the operation of the vacuum pump is reduced, and the service life of the vacuum pump is prolonged.

Second level filtration, vacuum pump oil filtration: oil vacuum pump uses vacuum pump

oil as the medium to vacuumize. During the operation of vacuum pump, oil will gradually

carbonize and deteriorate and become gelatinous when it works under high temperature for

a long time. In addition, the vacuum pump blades and other components will also have friction during rotation, which will produce some dust particles. These gelled oil products and dust particles are mixed in the vacuum pump oil for operation, so they must be collected in time through the oil filter. At this time, the vacuum pump filter can play a very good protective role, and the pollution is collected and contained by it.The third level of filtration, exhaust filtration: there are a lot of oil mist particles in the exhaust gas of vacuum pump. If they are not separated, these oil mist particles will be discharged together with the gas, forming what we usually call "smoke". When the vacuum pump "smoke", the working environment of the workshop will be polluted, and the oil of vacuum pump will also drain very fast, so we need to vacuum every day Pump oil. At this time, the exhaust filter can solve this problem. When the oil and gas mixture is discharged, it needs to pass through the high-precision fiberglass filter paper of the exhaust filter. The oil mist particles cannot directly pass through the fiberglass

filter paper in the form of liquid, so they are attached to the filter paper. At last, more and more oil mist particles are attached to the filter paper and integrated into the oil drop return vacuum pump. The clean gas is discharged smoothly through the fiberglass paper under a certain pressure, so the vacuum pump The filter can separate oil and gas.

Product features

1.Environmental Production

2.Favourable Price

3.Stable and constant pressure

4.Long service life

5.High efficiency

6.Durable and reliable

Product parameters

Model: | 532140159 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | ISO9001 |

Quality: | 100% Tested |

Working temperature | -10~+100℃ |

Working pressure | -21~210 bar |

Body Height (H-0) | 383 mm |

Total Height (H-TOTAL) | 383 mm |

Product Net Weight (WEIGHT) | 0.47Kg |

Largest Inner Diameter (Ø IN-MAX) | 35 mm |

Outer Diameter (Ø OUT) | 72 mm |

Product application

1.Chemical and petrochemical industry

2.Pharmaceutical industry

3.Breathing air

4.Prefiltration of sterile filters

5.Filling machines

6.Food & beverage industry

7.Packing machines

8.Process industry

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português