Product Details

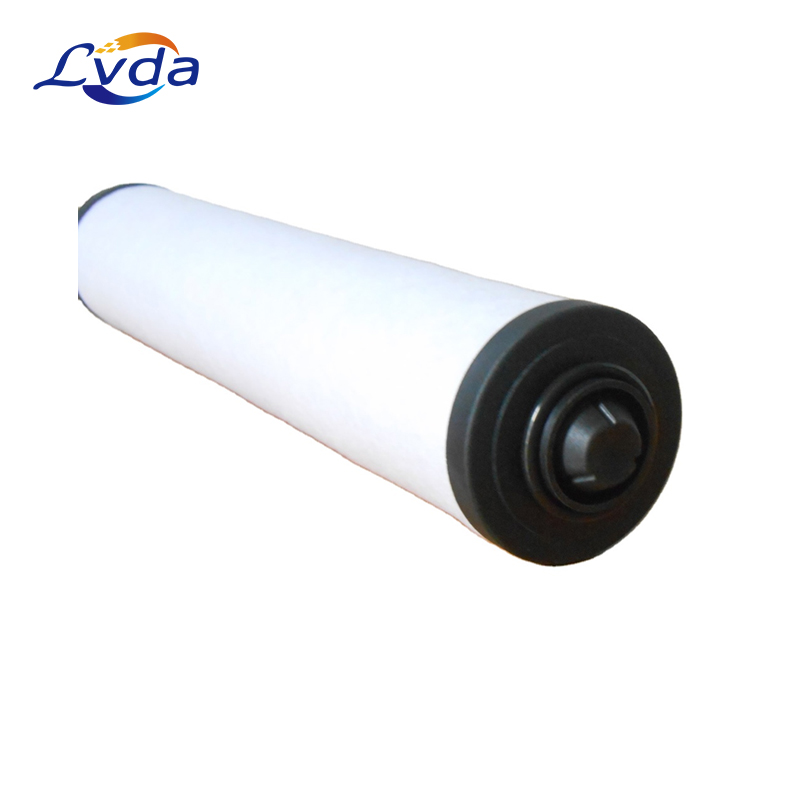

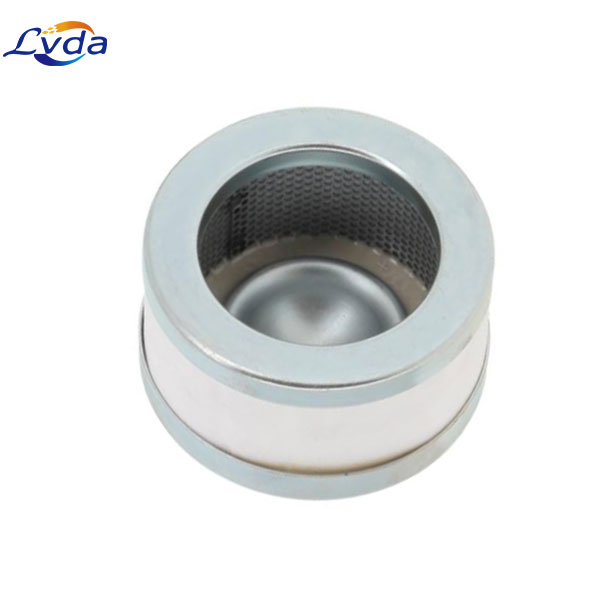

Busch oil filter 0532000507 is a vacuum accessory for oil ring vacuum pumps . Busch oil filter works to filter oil from dust and dirt during pump operation, helping to keep the oil clean. Therefore, the suction pump is cooled, avoiding heat, causing damage and reducing the life of the vacuum pump.

Currently, Busch oil filter is very commonly used in industrial parks, export processing zones, and manufacturing plants that use vacuum pump systems.

Select an oil filter with the right size and specifications for the vacuum pump in use. After choosing, just install it in the correct direction with the vacuum pump to be able to work.

When using the Busch oil filter, you must pay attention to regularly cleaning and changing the vacuum oil filter periodically (about 500h - 600h) to operate the machine.

When removing and installing the oil filter, it must be in the correct direction with the vacuum pump in use

It is recommended to use together with Busch VM100 and Becker M100 vacuum oils for the best performance when running the machine.

Product features

1.The efficiency of separating and filtering dirty oil is up to 99.99% to help remove impurities mixed in the oil when used.

2.Busch oil filter is capable of working continuously in high temperature environment.

3.Reduce noise levels to 4dB(A).

4.Busch oil filter can withstand good pressure up to 75PSIG.

5.Busch oil filter is made from anti-corrosion, water-resistant materials, which can be used in chemical environments for a long time.

6.Busch oil filter is not capable of conducting electricity and static electricity.

7.Products are manufactured on automatic lines, tested in a pressurized environment with 100% European quality standards before being put into use.

Product parameters

Model: | 532000507 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | ISO9001:2015 |

Quality: | 100% Tested |

Permissible Flow (FLOW) | 3.1 m3/h |

Body Height (H-0) | 507 mm |

Total Height (H-TOTAL) | 507 mm |

Product Net Weight (WEIGHT) | 0.67 Kg |

Largest Inner Diameter (Ø IN-MAX) | 35 mm |

Outer Diameter (Ø OUT) | 72 mm |

Product application

1. In the machine tool industry, at present, 85% of the machine tool transmission systems use hydraulic transmission and control. Such as grinder, milling machine, planer, broaching machine, press, shear, and modular machine tools.

2. In metallurgical industry, electric furnace control system, rolling mill control system, open hearth charging, converter control, blast furnace control, strip deviation and constant tension device all adopt hydraulic technology.

3. Hydraulic transmission is widely used in construction machinery, such as excavators, tire loaders, truck cranes, crawler bulldozers, tire cranes, self-propelled scrapers, graders and vibratory rollers.

4. In agricultural machinery, hydraulic technology is also widely used, such as combine harvesters, tractors and plows.

5. In the automotive industry, hydraulic off-road vehicles, hydraulic dump trucks, hydraulic aerial working vehicles and fire engines all use hydraulic technology.

6. In the light textile industry, hydraulic technology is applied to plastic injection molding machine, rubber vulcanizing machine, paper machine, printing machine and textile machine, etc

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português