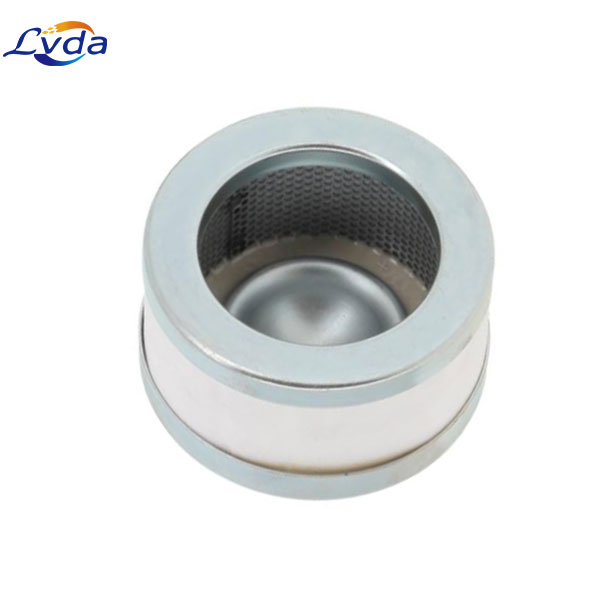

Product Details

It is used in mining and chemical industries. Vacuum filters also have a batch method, which is a method of repeating the injection of raw materials and filtering operations, but a method that can be worked continuously, that is, continuous method, is widely used.

When the vacuum filter is operated, the raw material is vacuum suctioned through the filtering surface of the drum inside the rotating drum. The solid particle group (cake) attached to the filter surface is peeled off by compressed air or the like at a rotating position of the drum.

It is a rotary filtering device capable of continuous filtering of sludge. The filter cloth acts on the back of the vacuum surrounded by the drum to inhale moisture in the sludge, and the drum-type is an Oliver filter, and the belt-type is a belt filter. Vacuum filters are easy to continuously filter and can be treated in large quantities, but are not suitable for volatile materials. It is difficult to cope with changes in the flow rate and viscosity of the undiluted solution.

Product features

1.High strength and operability

The filter element of vacuum pump has good bursting resistance and tensile strength in terms of quality. The raw material is special filter paper, which is processed by advanced technology, so that it can not only withstand the impact of gas, liquid and solid, but also has strong operability. Its size and size can be processed to understand and meet customers' different needs.

2.High separation efficiency and permeability

The second advantage of vacuum pump filter element is its high separation efficiency, strong permeability and small resistance. During operation, the filter element of the vacuum pump can withstand the test of liquid, gas and other impact forces, filter the gas or liquid, and ensure that it can pass the vacuum pump smoothly, thus reducing the probability of smoke from the vacuum pump.

3.Good material, long service life

The filter element of vacuum pump is made of special raw materials, which makes its structure loose and porous. This ensures that other substances will not react when contacting the filter element of vacuum pump through the vacuum pump, thus improving the tolerance of vacuum pump to external impact. In addition, the filter element of vacuum pump has strong operability, so the vacuum pump can be used efficiently and its service life is extended, The cost of frequently replacing the filter element of the vacuum pump is reduced.

The filter element of vacuum pump with good quality can be widely used in the industrial field and is praised by many customers because its advantages can meet the needs of consumers. In addition, the advantages of the filter element of the vacuum pump also cater to the development situation of the current environmental protection society, and solve the problem of environmental pollution in actual production and life.

Product parameters

Model: | 71064763 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 2000- 4000h |

Certificate: | ISO9001:2015 |

Quality: | 100% Tested |

Working temperature | -10 ~ +100℃ |

Work pressure different | 20-210bar |

Permissible Flow (FLOW) | 1.5 m3/h |

Body Height (H-0) | 227 mm |

Total Height (H-TOTAL) | 227 mm |

Product Net Weight (WEIGHT) | 0.295 Kg |

Largest Inner Diameter (Ø IN-MAX) | 41 mm |

Smallest Inner Diameter (Ø IN-MIN) | 5.5 mm |

Outer Diameter (Ø OUT) | 70 mm |

Product application

1.Chemical and petrochemical industry

2.Pharmaceutical industry

3.Filling machines

4.Food & beverage industry

5.Packing machines

6.Process industry

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português