Product Details

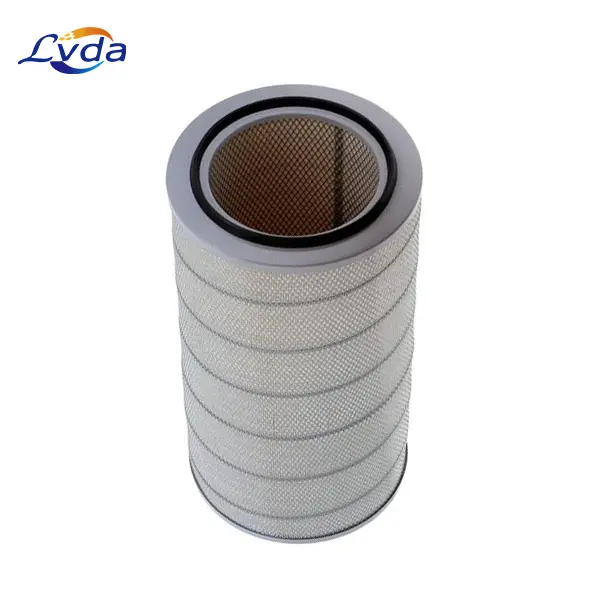

The SULLAIR 02250195-193 compressed air line filter replacement elements are designed to perform as the original. Line filter is a key component of your downstream air treatment system. The function of the line filter is to remove contaminants from the air once compressed before entering in the distribution network or at the point of use, they are always a critical part of the air treatment system and in most cases work hand in hand with dryer.

Pre-filter coalescing filters are ideal for basic water, oil, and dirt removal. They keep the air moderately clean and extend the life of your accessories and production machinery. Average general-purpose filter elements can catch particulates anywhere between 5 and 1 microns in size. They are often called pre-filter as they are normally installed first in the air treatment system.

The filter element is also the main principle of the filter. It is the purification equipment needed to purify the original ecological resources and reuse resources. The filter element is generally used in oil filtration, water filtration, air filtration and other filtration industries. It can remove a small amount of impurities in the filter medium, which can protect the normal operation of the equipment or the cleanness of the air. When the fluid passes through the filter element with a certain accuracy, its impurities are blocked, and the clean flow matters flow out through the filter element. The filter element is an important part of the filter. When the mixed gas containing impurities passes through the filter element, the liquid, oil mist, solid particles, oil vapor, hydrocarbons, odor, bacteria, etc. in the mixed gas will be filtered out;

Generally speaking, except that few filter elements are renewable, filter elements need to be replaced after a period of use (8000 hours).

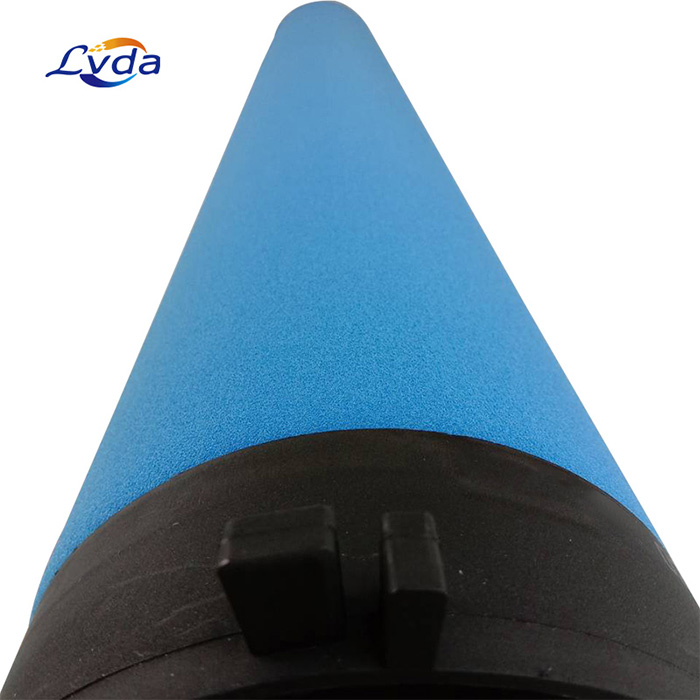

The LVDA filter element is a precision filter, also known as filter element. It is composed of stainless steel skeleton with corrosion resistance, excellent structural performance and different structures. It has high welding strength and low air flow resistance. In order to make the medium contact area larger, the Company has improved the filtration rate and the filtration effect. In order to ensure high efficiency of oil removal, sealed foam coated sleeve with oil resistant and acid resistant chemical corrosion is used on the surface to prevent coalesced liquid from entering the air flow again.

Product features

1. High porosity, good air permeability, low resistance and low pressure difference;

2. After forming into a folded shape, the filtering area is large and the dirt holding capacity is large;

3. High temperature resistance, corrosion resistance, suitable for high viscous liquid filtration;

4. Good regeneration performance, can be used repeatedly after chemical cleaning, high temperature and ultrasonic cleaning;

5. All stainless steel structure, wide chemical compatibility;

6.Made of new material only,Specifications as per SULLAIR or better,ISO manufacturing process,High Quality Media,Product photos are for reference only.

Product parameters

| Raw water pressure | 10KG/cm² |

| Filtration accuracy | 0.01-3um |

| Filter

area | 99.90% |

| Exit and entry diameter | Customized according to actual needs |

Working maximum

differential

pressure | 0.2Mpa |

| Operating temperature | -30~110℃ |

| Service

life | 6000h |

| Applicable objects | Air |

| Filter form | Wire wound filter element |

| Use | Air filtration |

| Material | Imported glass fiber |

Product application

1.Chemical industry: filtration of various chemicals such as water, solvent, acid, alkali, emulsion filtration, filtration of impurities in coatings;

2.Petroleum machinery: various oil products, such as filtration and clarification of fuel oil, lubricating oil, cutting oil, separation of fermentation products and bacteria, separation of oil and water;

3.Biochemistry: removal of miscellaneous bacteria, concentration and separation of bacterial cells, and removal of mycoplasma during fermentation;

Electronic industry: manufacturing of ultrapure water, semiconductor manufacturing, air purification for clean rooms, fine filtration of drugs for optical disc manufacturing;

4.Pharmaceutical medical treatment: manufacture of pyrogen-free purified water, sterilization of injection, clarification, sterilization and filtration of APIs, intermediates, chemical raw materials, etc.;

5.Food processing: removal of yeast and mold in wine, beer and carbonated beverages, clarification and filtration of sugar solution; clarification and sterilization filtration of fruit juice.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português