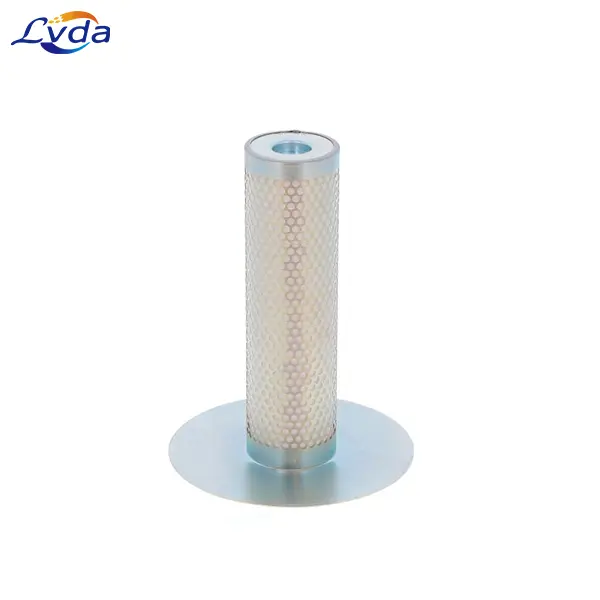

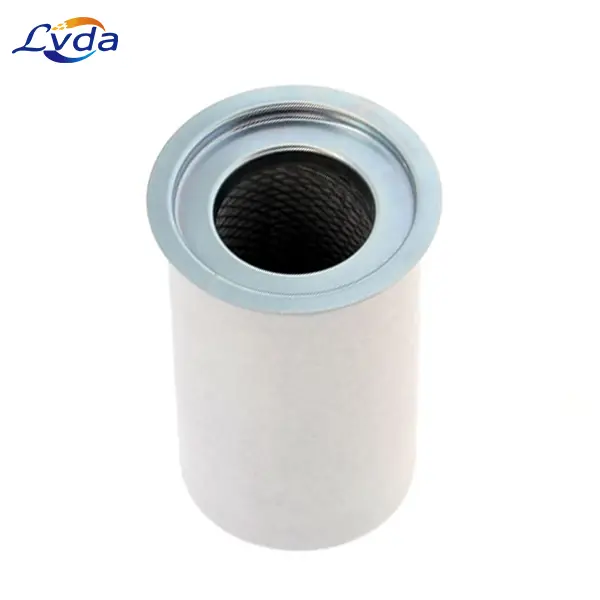

Product Details

BOPP Biaxially Oriented Polypropylene filter media is a type of biaxially stretched film made from polypropylene, commonly used in filtration and separation applications. BOPP filter media has many excellent properties, making it widely used in various industries. Here are some key points about BOPP filter media:

Properties

1. High Strength and Low Elongation: Due to the biaxial stretching, BOPP filter media has high strength and low elongation, allowing it to maintain a stable shape during use.

2. Chemical Resistance: BOPP has good resistance to most chemicals, including acids, bases, and solvents, making it suitable for various filtering environments.

3. Thermal Stability: BOPP filter media has good thermal stability and can maintain its physical and chemical properties at higher temperatures.

4. Air Permeability and Filtration Efficiency: The porosity and air permeability of BOPP filter media can be adjusted through the production process to meet different filtration needs. It provides efficient filtration while maintaining good air permeability.

5. Cleanliness: The production process of BOPP filter media is strictly controlled to achieve high cleanliness, making it suitable for applications with high cleanliness requirements.

Applications

1. Liquid Filtration: BOPP filter media is widely used in water treatment, beverage filtration, chemical liquid filtration, and other applications.

2. Air Filtration: Due to its good air permeability and filtration efficiency, BOPP filter media is also used in air purification and industrial dust removal.

3. Healthcare and Medical: BOPP filter media can be used in medical devices such as infusion sets and respirators.

4. Food and Beverage Industry: BOPP filter media is used to filter food and beverages to ensure product purity and safety.

5. Electronics and Semiconductor Industry: BOPP filter media is used in cleanroom filtration during the manufacture of electronic and semiconductor components to prevent particle contamination.

Manufacturing Process

The production of BOPP filter media typically involves the following steps:

1. Extrusion and Casting: Polypropylene resin is melted and extruded through an extruder to form a thick sheet.

2. Longitudinal Stretching: The thick sheet is longitudinally stretched at high temperature to align the molecular chains longitudinally.

3. Transverse Stretching: The longitudinally stretched film is transversely stretched at high temperature to align the molecular chains horizontally.

4. Setting and Cutting: After stretching, the film is set and then cut into different specifications of filter media.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português