Product Details

There will always be many pollutants in the compressed air system: for example, abrasive solid particles such as dust, dust particles, iron filings and scales, compressor lubricants (mineral or synthetic), condensate droplets and acidic condensate, as well as oil and hydrocarbon mist. If these pollutants are not removed, they will increase the maintenance cost of pneumatic equipment, cause failures of instruments and control devices, damage product precision and finish, and pollute process procedures. The precision air filter and filtering system can remove these pollutants, so that your compressed air system can meet the application requirements of high-quality compressed air. Whether it is required by factories, instruments or medical equipment, it can help you maintain a stable and consistent compressed gas supply quality, and reduce the operating cost as much as possible.

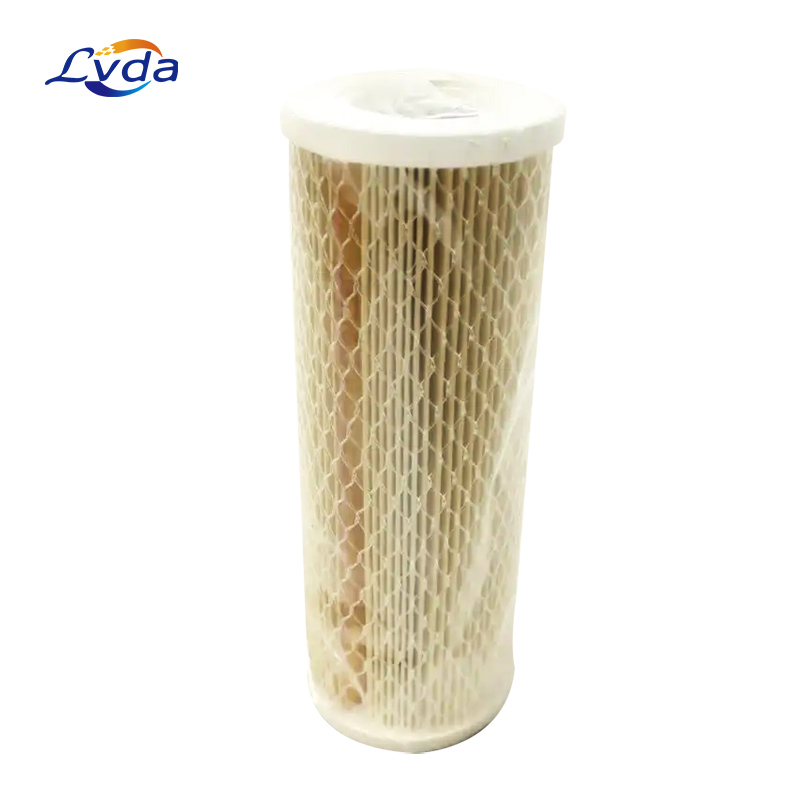

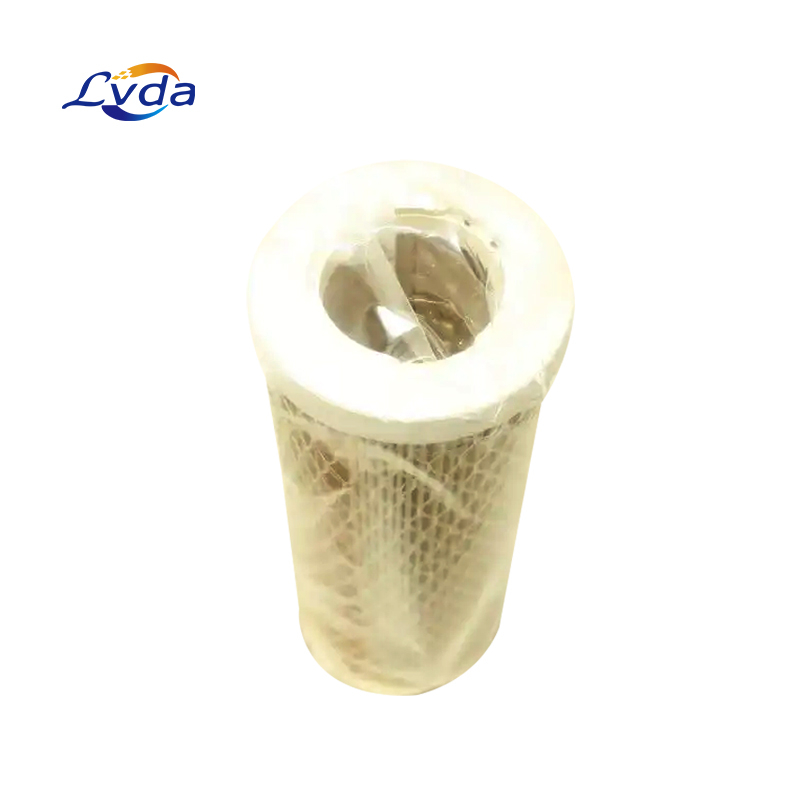

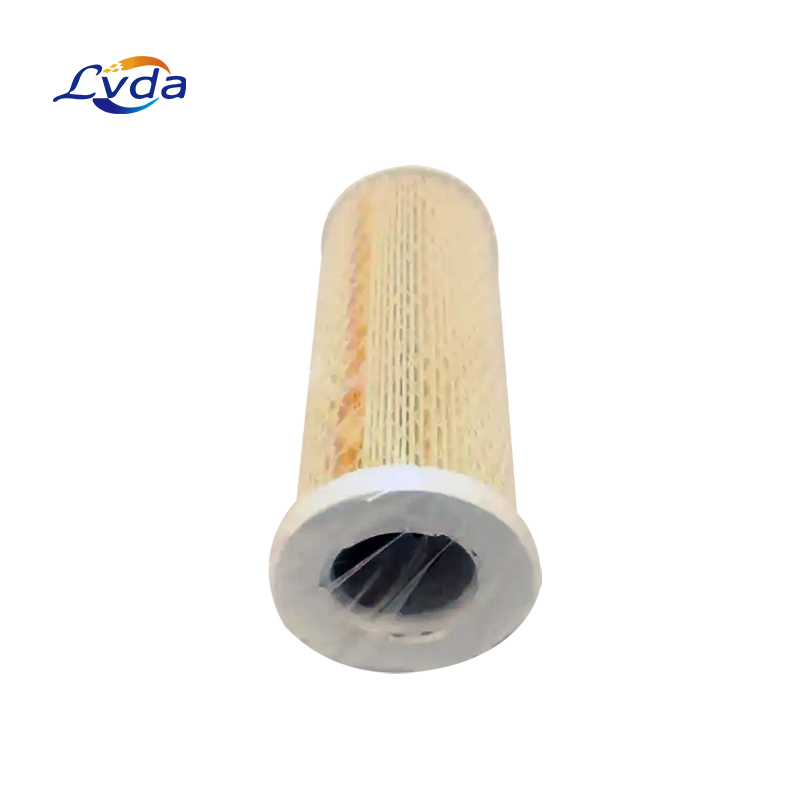

The precision filter elements of various compressed air filters developed by LVDA Filter Company have been widely used in petroleum, electronics, chemical industry, metallurgy, power generation, pharmacy, food and other industries. Our company has developed a precision air filter element to replace this filter according to the needs of users. This kind of precision filter element is made of imported filter materials and stainless steel framework, which has the characteristics of high filtration efficiency, corrosion resistance, low airflow resistance, long service life, etc. It is made entirely according to the specifications of the original filter element, and its overall dimensions are consistent with the original ones. It can be directly installed on the precision filter. The performance and use effect of our products that replace imported filter elements can be completely comparable to those of imported products, and have a very high cost performance ratio. Please rest assured that you can use them.

Product features

A) High efficiency

B) Long service lifetime

C) Good anti-humidity performance

D) No distortion of pleats

Product parameters

Maximum Operating Temperature (F) | 175 |

Standard Seal Material | Urethane |

Filter Rating (%) | NA |

Micron Rating (µm) | 3 |

Length (inch) | 1.5 |

Filter Type | Particulate |

Outside Diameter (inch) | 6 |

Brand | Finite |

Product Series | HN3S, HN4S |

Application | Compressed Air and Gas |

Maximum Operating Temperature | 79 °C |

Model Number | 3PU15-060 |

Type | Compressed air filter element |

Dimension | Standard |

Working Temperature | According to customer's request |

Work Pressure Different | Customized |

Material | Glassfiber, Stainless steel, Filter paper |

Filter Precision | 0.01-1μm |

Life span | 6000- 8000h |

MOQ | 10 pieces |

Lead Time | Around 3-5 days after order confirmed |

Advantages | 1.Adopt imported glassfiber media |

2.High filtration effciency over 99.9% |

Package | PP bag inside, Inner carton, Export carton outside, or Wooden box as your requirement |

Shipping Method | By sea, by air, by express |

Product application

1. Construction machinery industry: excavator, loader, roller, rotary drilling rig, paver

2. Power industry: generator sets, mobile power stations

3. Petrochemical industry: fuel dispensers, oil tankers, mobile fuel tankers

4. Mechanical processing equipment: various mechanical hydraulic system filters such as machining center, lathe, milling machine, bending machine, etc

5. Agricultural machinery: harvester, tractor, lawn mower

6. Transport vehicles: heavy trucks, mixer trucks, buses, sprinklers

7. Ships

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português