Product Details

Sakura Oil Filters are designed and made to the exact standard to reduce frictional wear by eliminating the particulates release from frictional parts and combustion. This enhances efficiency and life expectancy of the engine.

Sakura Fuel Filters eliminate fine contaminant from entering the fuel, injection system,keeping them clean and overall cost down.

Product features

1. Extensive Coverage:

Provide filter requirements for the world's major well-known brand machinery to achieve global coverage.

2. Precise Positioning:

Through early communication and assistance, clarify customer needs, and accurately position the product system and market price.

3. Technology Leadership:

Using a number of independent patented technologies, the production has extraordinary stability and reliability.

4. Special Development:

According to the model you provide, we can customize high-quality products for you.

5. Energy Efficiency:

Carefully implement the industry standard, choose the best filter material, save maintenance cost for users, improve the rate of return on investment.

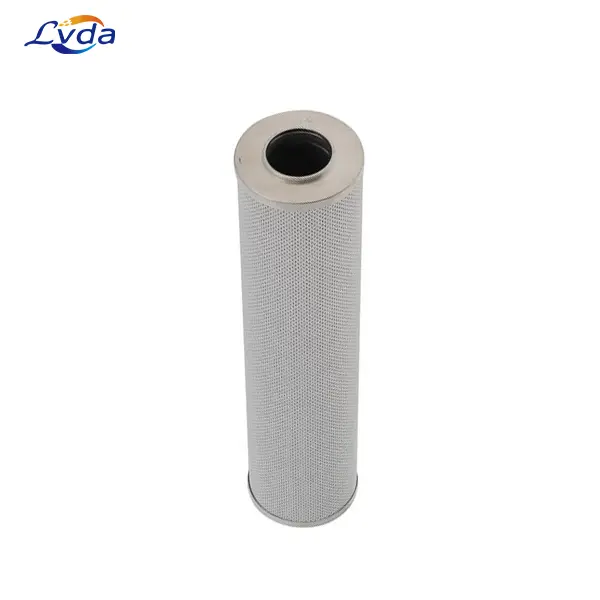

Product parameters

Car Model: | Truck & Tractor |

Function | Filtrate Dust |

Size: | 110 * 205 mm |

Initial Pressure Drop | <=0.3kpa |

Initial Efficiency | >=99.8 |

Material: | Filter Paper |

Application: | Truck & Tractor |

Function: | Remove Dust Impurities |

Service: | Online Service |

Quality: | High-performance |

Package: | Neutral Packing |

Brand: | LVDA |

Certification: | ISO 9001/TS 16949:2009 |

Quality: | 100% Professional Test |

Efficiency: | 99% |

Filtration Grade: | Hepa Filter |

Application: | For truck, trailer, marine or other diesel replacement, construction machines |

Model | Element |

Filter Type | Oil Filter |

Filter Info | Full Flow, Eco |

H 1 (mm) | 205.7 |

H 2 (mm) | 195.5 |

OD 1 (mm) | 110 |

OD 2 (mm) | 110 |

ID 1 (mm) | 26.7 |

Contain (Pcs) | 12 |

Reference Number | 152049Z00C NISSAN

23476561 VOLVO |

Product application

1. Metallurgy: It is used for the filtration of the hydraulic system of rolling mills and continuous casting machines and the filtration of various lubricating equipment.

2. Petrochemical: used for separation and recovery of finished products and intermediate products in the process of oil refining and chemical production, liquid purification, purification of magnetic tapes, optical discs and photographic films in manufacturing, oil field well injection water and natural gas for particle removal and filtration.

3. Textiles, electronics and pharmaceuticals

4. Power Plant

5. Steel mills

6. Subway engineering

7. Chemical plant

8. Ships

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português