Product Details

Common sense of good and bad filters

All filters are used to protect engine parts, clean, prolong engine service life. It is incorrect to judge whether the filter is good or bad from the surface of various filters and the length of filter service time. To truly determine whether the filter is good or bad, the following aspects should be considered first:

1. Filter paper quality

The filter paper with good quality is similar to the filter paper with poor quality on the surface. It can be obviously different only if it is inspected by the inspection equipment of a professional factory. The quality of the filter paper is related to the filter efficiency. The filter paper with good quality filters more impurities, iron and dust in the system, while the filter paper with poor quality filters less impurities, iron and dust, The relevant parts of the engine are easy to wear.

2. Filter efficiency of filter

It is mainly determined by the quality of the filter paper used in the filter. Only when the filter efficiency reaches more than 96% can the filter be regarded as a qualified product. At the same time, in the same place, and from different manufacturers, the use effect of the filter is different. It is obviously different that the driver's feeling of the engine and the smoke intensity of the vehicle exhaust during engine starting and driving, and the wear of the engine parts during engine repair.

3. Adhesive material between filter paper and end cover

With high-quality filter paper, there is also a high-quality adhesive. If the selection is not correct, the filter paper in the filter is not firmly bonded with the upper and lower end covers, and it is easy to fall off when encountering oil during use, without viscosity, resulting in short circuit and no filtering effect.

4. Guarantee of production process

Seen from the surface, the filter paper and filter paper cannot be stuck together, and must be transparent under light. If no light transmission can be seen under the light, the adhesion between filter papers will affect the flow of the entire empty filter cake. The service life is short, resulting in insufficient power and weakness. It is difficult to remove dust during the cleaning process. A good air filter is a filter paper that does not adhere to each other, has strong light transmittance, is suitable for the engine intake standard, has a long service life, and is easy to clean.

5. Process of air filter

Select high-quality materials to produce filters, and the production process is the backing to ensure product quality. There are many production links of the filter. How to ensure the protection and purification of the filter in the use process, ensure the flow and ensure the normal operation of the engine requires the process assurance of each link in the production process.

Product features

1. Longer service life: Regular use of LVDA spare parts to maintain your equipment can ensure that your device has a longer service life. We guarantee that each new component has the same good performance as the replaced component.

2. High quality: our original parts are manufactured according to the same strict standards as the compressor you have installed. These parts have passed the durability test and proved to be a better guarantee for your investment.

3. Reliability and productivity: The use of original parts can fundamentally reduce the risk of production stoppage, because production stoppage is not only costly, but also may affect product quality, delivery time and profit margin. In short, original parts enable your compressed air unit to perform better.

4. Energy saving and cost-effectiveness: regular replacement and use of LVDA parts will enable your compressed air device to have a longer service life and achieve a smaller average pressure drop, so as to achieve energy conservation, achieve cost-effectiveness and provide a larger exhaust volume at a lower cost of ownership.

Product parameters

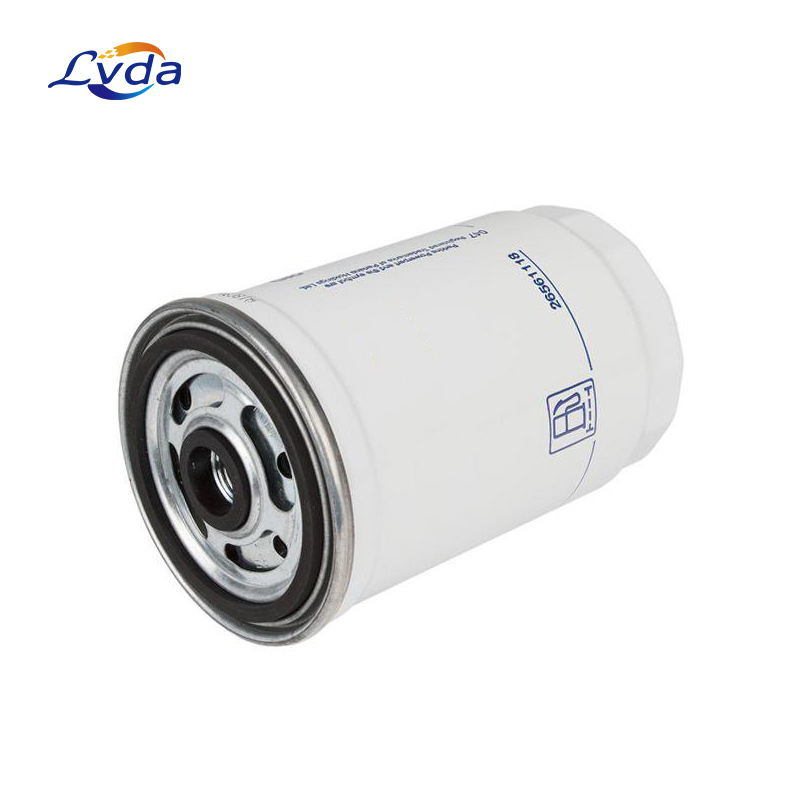

Part number | 26561118 |

Application | Diesel Engine |

Wattanty | 1 year |

Description | Aftermarket |

Condition | Brand new |

Size | 11cm*12cm*19cm |

Weight (kg) | 0.8 |

Range of application | Used for Perkins Engine |

Filter Type | Diesel Fuel Filter Assy |

Material | Metal+Filter Paper |

Filtration Grade | 10-20 Micron |

Quality Standard | 100% Tested |

performance | Alkali resistant,

low temperature resistant,

high temperature resistant,

acid resistant |

Product application

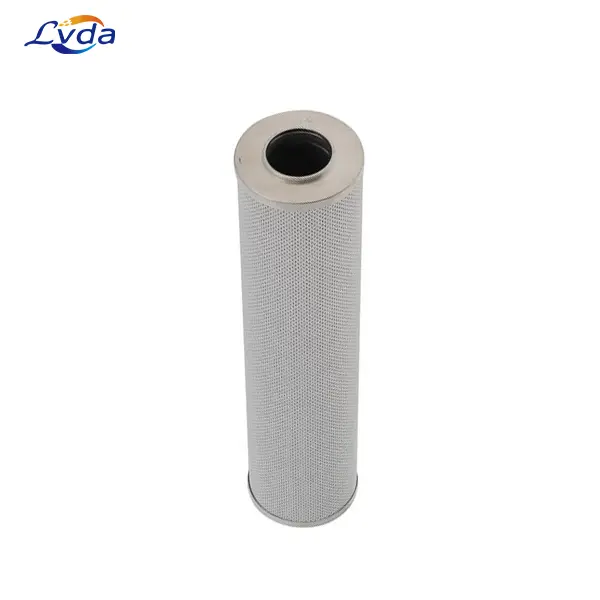

1. Metallurgy: It is used for filtering the hydraulic system of steel rolling mill and continuous casting machine and filtering various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in oil refining and chemical production, particle removal and filtration of oilfield well water and natural gas.

3. Textile: purification and uniform filtration of polyester melt during wire drawing, protective filtration of air compressor, oil and water removal of compressed gas.

4. Electronics and pharmacy: pretreatment filtration of reverse osmosis water and deionized water, pretreatment filtration of cleaning solution and glucose.

5. Thermal power and nuclear power: purification of lubricating system, speed control system and bypass control system oil of gas turbine and boiler, and purification of feed pump, fan and dust removal system.

6. Mechanical processing equipment: lubrication system and compressed air purification of paper machinery, mining machinery, injection molding machines and large precision machinery, and dust recovery and filtration of tobacco processing equipment and spraying equipment.

7. Railway internal combustion engine and generator: filtering of lubricating oil and engine oil.

8. Automobile engine and construction machinery: air filter, engine oil filter, fuel filter for internal combustion engine, various hydraulic oil filters, diesel oil filters and water filters for construction machinery, ships and trucks.

9. Various lifting and handling operations: hoisting, loading and other engineering machinery to fire fighting, maintenance, handling and other special vehicles, ship's cargo winch, windlass, blast furnace, steelmaking equipment, ship lock, ship door hoist, theater's lifting orchestra and lifting stage, various automatic conveyor lines, etc.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português