Product Details

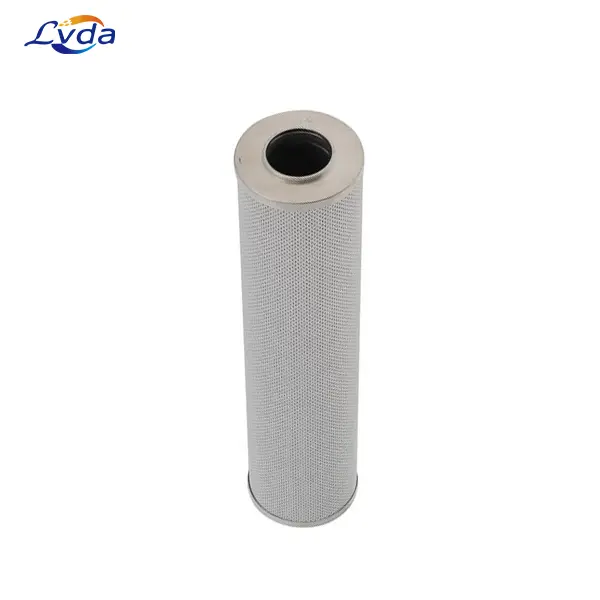

Atlas air compressor accessories - oil separator

Only the filter element of oil separator replaced by the original Atlas air compressor can provide extremely low oil content in combination with low pressure difference. This means that the lower oil consumption and longer service life of the fine filters installed later can produce better air quality and lower operating costs.

Maintenance and replacement of oil-gas separator

The oil-gas separator is a component that separates the screw lubricating oil from the compressed air. Under normal operation, the service life of the oil-gas separator is about 3000 hours, but the quality of the lubricating oil and the filtering accuracy of the air have a huge impact on its service life. It can be seen that the maintenance and replacement cycle of the air filter element must be shortened under severe service conditions, and it may even be considered to install a front air filter. The oil-gas separator must be replaced when it expires or when the pressure difference between front and back exceeds 0.12Mpa. Otherwise, the motor will be overloaded, and the oil-gas separator will be damaged and oil will escape. Replacement method: remove all control pipe joints installed on the oil-gas drum cover. Take out the oil return pipe extending into the oil and gas barrel on the oil and gas barrel cover, and remove the fastening bolts on the upper cover of the oil and gas barrel. Remove the upper cover of the oil and gas drum and take out the oil. Remove the asbestos pad and dirt stuck on the upper cover plate. When installing a new oil-gas separator, note that the upper and lower asbestos pads must be stapled. When pressing, the asbestos pads must be placed in order, or chaos will occur. Install the upper cover plate, oil return pipe and each control pipe as they are and check for leaks.

Filter element of oil-gas separator: according to the working principle of screw air compressor, we know that the air just compressed contains a lot of oil molecules, and the main function of filter element of oil-gas separator is to separate oil from gas. The separated compressed air enters the next stage, and the oil drops will concentrate at the bottom of the filter element and return to the lubrication system through the oil return pipe.

Each model of Atlas Copco's oil separators. It can resist to different dropout voltages, at most to 20psi(1.5KG per sq.cm). The shape and installation method of each different structure of oil separator can meet each demand of screw compressors. The separation ability can acheive 1-3ppm. The treatment of gas range is in 1-50 cubic meters per minute, meeting requirements of each compressor model.

It can be replaced for Atlas Copco original parts, which are much more expensive. The price is only 1/3 or 1/2 compared with Atlas Copco original ones. Additionally, it has got same after-sale claim policies as Atlas Copco ones. No worries and decrease costs.

Product features

1. Longer service life: Regular use of LVDA spare parts to maintain your equipment can ensure that your device has a longer service life. We guarantee that each new component has the same good performance as the replaced component.

2. High quality: our original parts are manufactured according to the same strict standards as the compressor you have installed. These parts have passed the durability test and proved to be a better guarantee for your investment.

3. Reliability and productivity: The use of original parts can fundamentally reduce the risk of production stoppage, because production stoppage is not only costly, but also may affect product quality, delivery time and profit margin. In short, original parts enable your compressed air unit to perform better.

4. Energy saving and cost-effectiveness: regular replacement and use of LVDA parts will enable your compressed air device to have a longer service life and achieve a smaller average pressure drop, so as to achieve energy conservation, achieve cost-effectiveness and provide a larger exhaust volume at a lower cost of ownership.

Product parameters

Operating temperature | 50 (℃) |

Maximum working differential pressure | 21 (MPa) |

Filtering precision | 0.1(um) |

Inlet and outlet diameter | 100 (mm) |

Performance | High temperature resistance

alkali resistance |

Raw water pressure | 21 (KG/c ㎡) |

Filter area | 10 |

Purpose | Oil gas separation |

Material | stainless steel |

Filter element type | folding filter element |

Product application

1.Power plant

2.Steel mill

3.Subway engineering

4.Chemical factory

5.Ship

6.Paper mill

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português