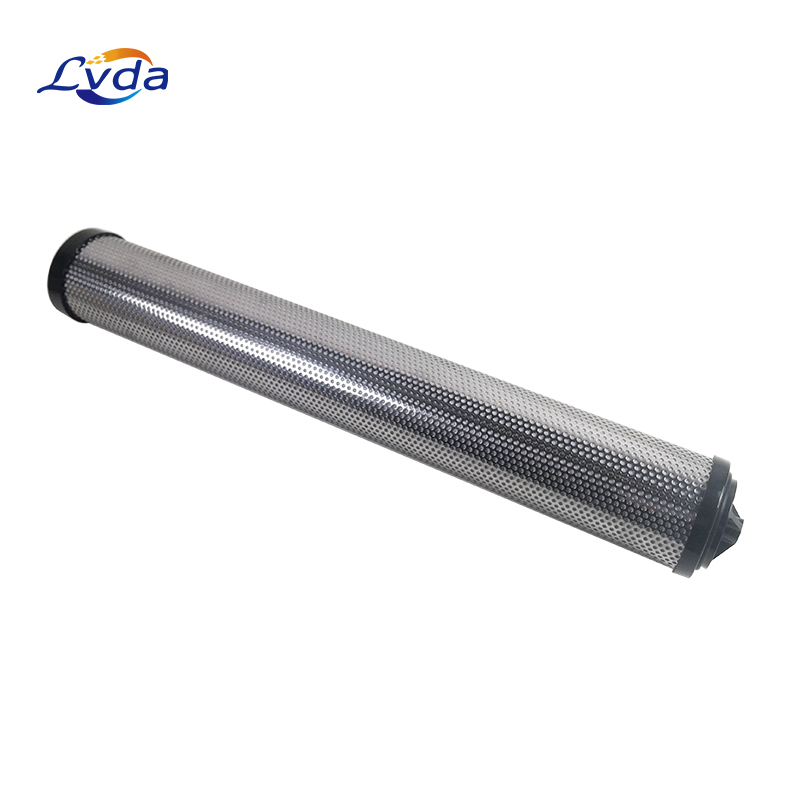

Product Details

The filter element is a high efficiency filter element, and the filtration efficiency can reach 99.999%. All the filtration products of LVDA Company use the American strong hydrophobic and oil repellent fiber filter material, which has good oil and water removal effects. The PPm value after filtration can be ≤ 3ppmw/w. At the same time, a round hole with good permeability and high strength skeleton are used to reduce the resistance caused by the fluid. 1617707302 filter element adopts German fine open hole sponge, which can effectively prevent oil and water from being carried away by high-speed airflow, so that small oil drops passing by can gather at the lower end of filter element sponge and be discharged to the bottom of filter container. A reliable sealing ring is used at the joint of the filter element and the filter housing to ensure that the air flow is not short circuited and prevent impurities from directly entering the downstream without passing through the filter element. LVDA Filter Cartridge Factory is always at the forefront of technology upgrading products.

Atlas Atlas nitrogen machine degreasing filter element 1617707302 Filter element grade:

Level 1: filtering accuracy: 0.01µ, residual oil content: 0.01ppm (oil removal and deodorization filter element)

Grade 3: filtration precision: 0.01µ, residual oil content: 0.01pp

Grade 5: filtering accuracy: 0.01µ, residual oil content: 0.01ppm

Grade 7: filtering accuracy: 3µ, residual oil content: 1ppm

Grade 9: filtering accuracy: 5µ, residual oil content: 5ppm

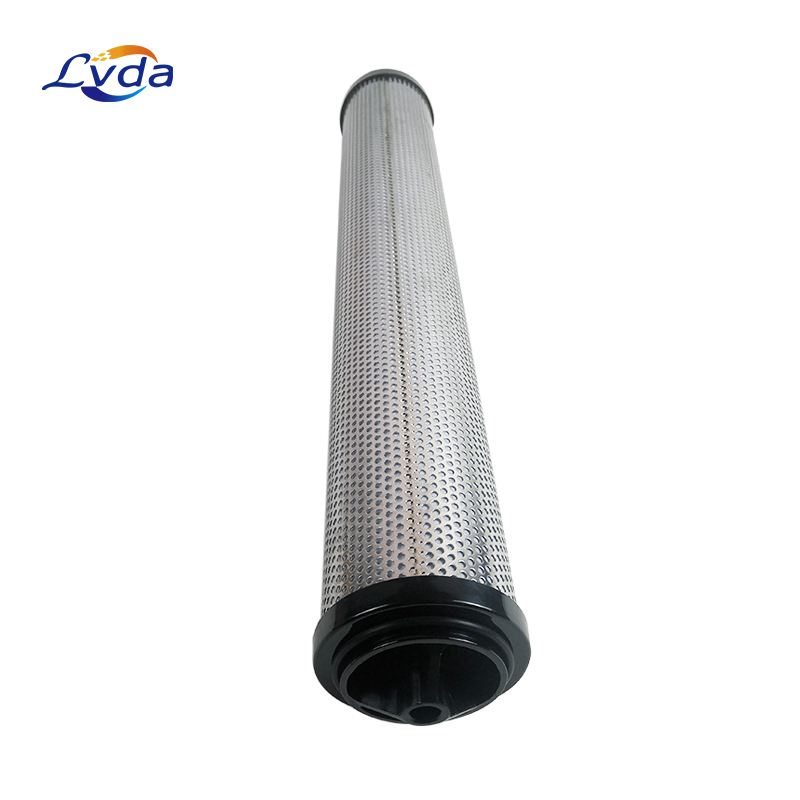

End cap

Stainless steel or carbon steel material, galvanized or nickel plated surface, durable, not easy to rust, high temperature resistance, high pressure resistance, anti-corrosion

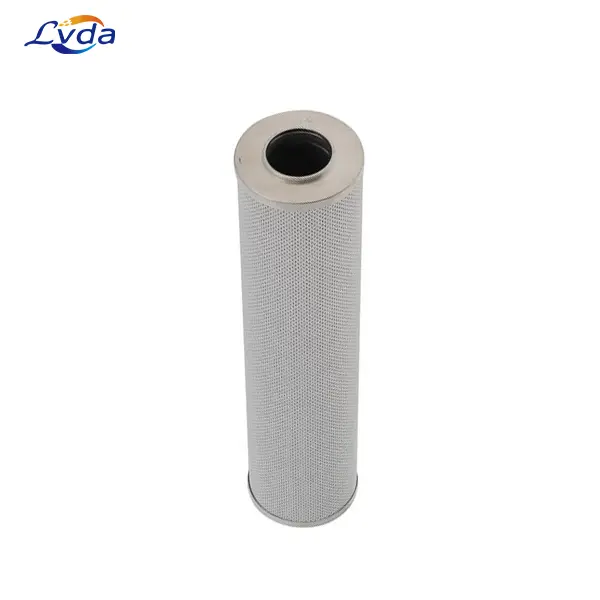

Filter material

Metal mesh, glass fiber, oil filter paper, a variety of filter materials can be selected. The selection of high-quality filter materials has good filtering effect, strong permeability, and large dirt holding capacity!

Skeleton

The interface shall be regular, the surface shall be smooth, made of stainless steel or carbon steel, the surface shall be galvanized or nickel plated, durable, not easy to rust, and resistant to high temperature, high pressure and corrosion.

We mainly produce filter elements, as long as customers provide product pictures or

Sample, size and other information. We can produce durable and high-quality products for customers.

We mainly produce filter elements, as long as customers provide product pictures or

Sample, size and other information. We can produce durable and high-quality products for customers.

Product features

1. High porosity, good air permeability, low resistance and low pressure difference;

2. The filtering area is large and the dirt holding capacity is large;

3. High temperature resistance, corrosion resistance, suitable for high viscous liquid filtration;

4. Good regeneration performance, can be used repeatedly after chemical cleaning, high temperature and ultrasonic cleaning;

5. Wide chemical compatibility;

Product parameters

Raw water pressure | 5MPa |

Filter accuracy | 0.1 microns |

Filter area | 0.5 square meters |

Entry and exit | 100mm |

The maximum

pressure difference | 0.25MPa |

Packaging | wooden box |

Storage life | 3 years |

Use temperature | 0-100 ℃ |

Craft | folding process |

Efficacy air | removal of oil |

Life | 6000H |

Product application

1.Chemical industry: filtration of various chemicals such as water, solvent, acid, alkali, emulsion filtration, filtration of impurities in coatings;

2.Petroleum machinery: various oil products, such as filtration and clarification of fuel oil, lubricating oil, cutting oil, separation of fermentation products and bacteria, separation of oil and water;

3.Biochemistry: removal of miscellaneous bacteria, concentration and separation of bacterial cells, and removal of mycoplasma during fermentation;

3.Electronic industry: manufacturing of ultrapure water, semiconductor manufacturing, air purification for clean rooms, fine filtration of drugs for optical disc manufacturing;

4.Pharmaceutical medical treatment: manufacture of pyrogen-free purified water, sterilization of injection, clarification, sterilization and filtration of APIs, intermediates, chemical raw materials, etc.;

5.Food processing: removal of yeast and mold in wine, beer and carbonated beverages, clarification and filtration of sugar solution; clarification and sterilization filtration of fruit juice.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português