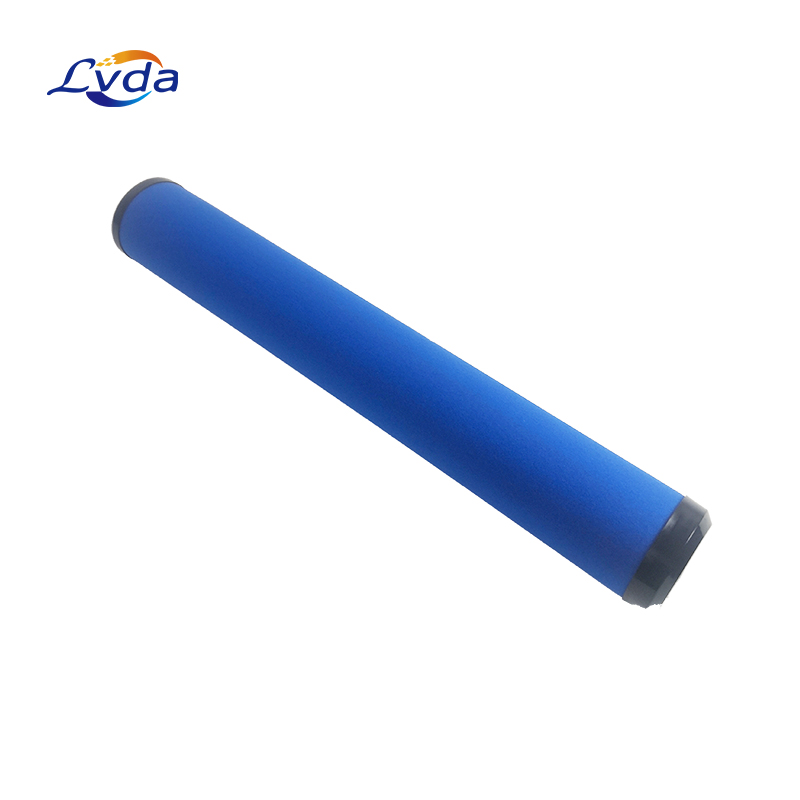

Product Details

The filter element is also the main principle of the filter. It is the purification equipment needed to purify the original ecological resources and reuse resources. The filter element is generally used in oil filtration, water filtration, air filtration and other filtration industries. It can remove a small amount of impurities in the filter medium, which can protect the normal operation of the equipment or the cleanness of the air. When the fluid passes through the filter element with a certain accuracy, its impurities are blocked, and the clean flow matters flow out through the filter element. The filter element is an important part of the filter. When the mixed gas containing impurities passes through the filter element, the liquid, oil mist, solid particles, oil vapor, hydrocarbons, odor, bacteria, etc. in the mixed gas will be filtered out;

Generally speaking, except that few filter elements are renewable, filter elements need to be replaced after a period of use (8000 hours).

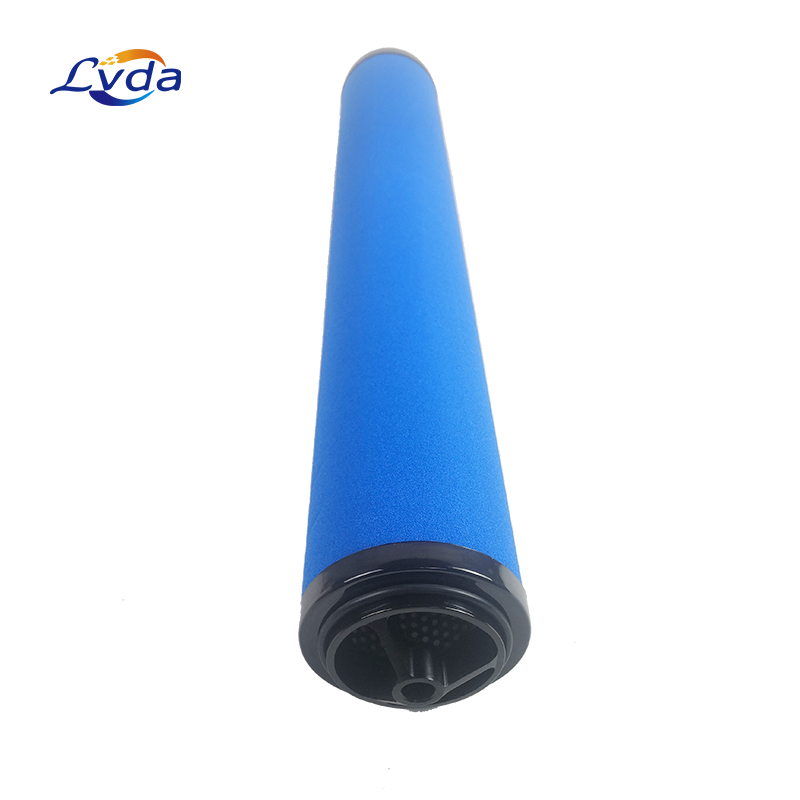

End cap

Stainless steel or carbon steel material, galvanized or nickel plated surface, durable, not easy to rust, high temperature resistance, high pressure resistance, anti-corrosion

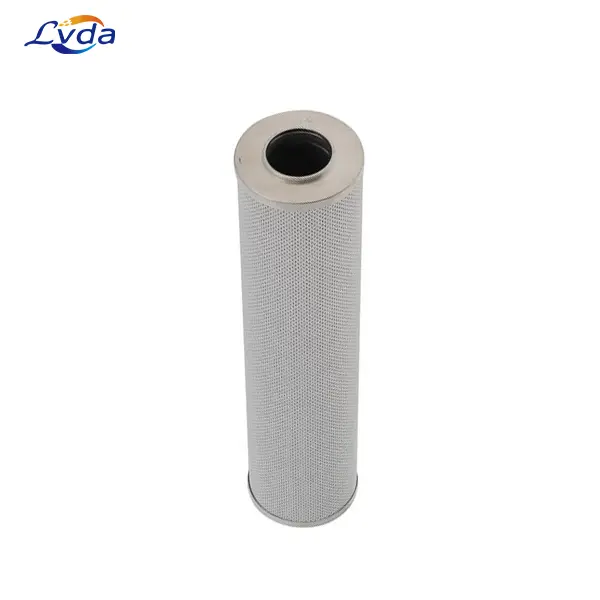

Filter material

Metal mesh, glass fiber, oil filter paper, a variety of filter materials can be selected. The selection of high-quality filter materials has good filtering effect, strong permeability, and large dirt holding capacity!

Skeleton

The interface shall be regular, the surface shall be smooth, made of stainless steel or carbon steel, the surface shall be galvanized or nickel plated, durable, not easy to rust, and resistant to high temperature, high pressure and corrosion.

We mainly produce filter elements, as long as customers provide product pictures or

Sample, size and other information. We can produce durable and high-quality products for customers.

Product features

1. High porosity, good air permeability, low resistance and low pressure difference;

2. After forming into a folded shape, the filtering area is large and the dirt holding capacity is large;

3. High temperature resistance, corrosion resistance, suitable for high viscous liquid filtration;

4. Good regeneration performance, can be used repeatedly after chemical cleaning, high temperature and ultrasonic cleaning;

5. All stainless steel structure, wide chemical compatibility;

6.Made of new material only,Specifications as per SULLAIR or better,ISO manufacturing process,High Quality Media,Product photos are for reference only.

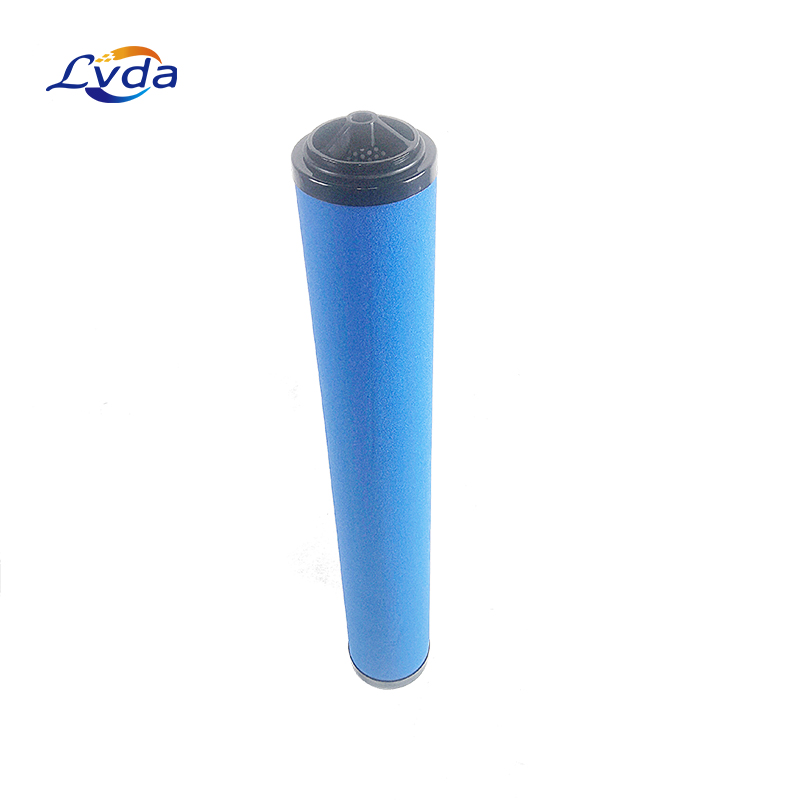

Product parameters

| Raw water pressure | 5MPa |

| Filter accuracy | 0.01 microns |

| Filter area | 0.5 square meters |

| Entry and exit | 100mm |

The maximum

pressure

difference | 0.25MPa |

| Packaging | wooden box |

| Adhesive | epoxy resin+curing agent |

| Surface processing | electric polishing |

| Use temperature | 0-100 ℃ |

| Craft | folding process |

| Efficacy air | removal of oil |

| Life | 6000H |

| Uses | air filtration |

| Material | HV filter paper |

Product application

1.Chemical industry: filtration of various chemicals such as water, solvent, acid, alkali, emulsion filtration, filtration of impurities in coatings;

2.Petroleum machinery: various oil products, such as filtration and clarification of fuel oil, lubricating oil, cutting oil, separation of fermentation products and bacteria, separation of oil and water;

3.Biochemistry: removal of miscellaneous bacteria, concentration and separation of bacterial cells, and removal of mycoplasma during fermentation;

3.Electronic industry: manufacturing of ultrapure water, semiconductor manufacturing, air purification for clean rooms, fine filtration of drugs for optical disc manufacturing;

4.Pharmaceutical medical treatment: manufacture of pyrogen-free purified water, sterilization of injection, clarification, sterilization and filtration of APIs, intermediates, chemical raw materials, etc.;

5.Food processing: removal of yeast and mold in wine, beer and carbonated beverages, clarification and filtration of sugar solution; clarification and sterilization filtration of fruit juice.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português