Product Details

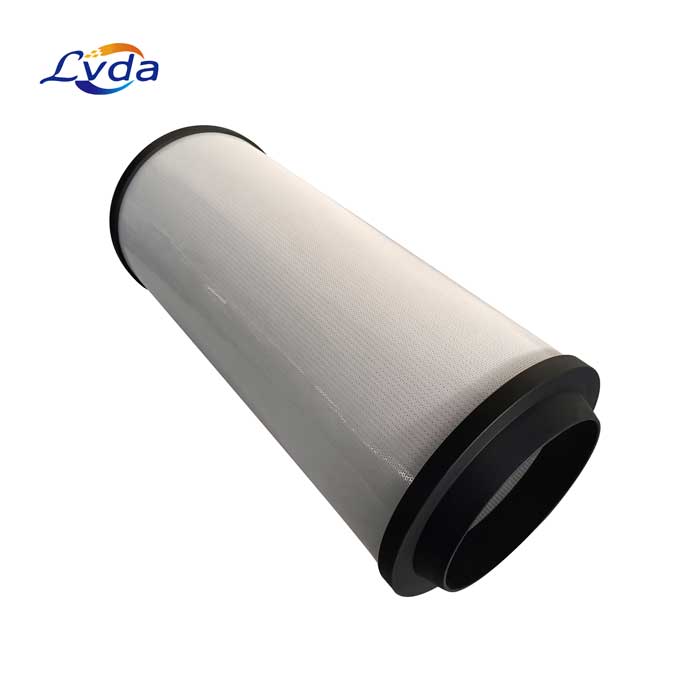

The PELF-PM-9-HF-2-PL-005-PES-PA V-1 filter element replacement has the same dimensions and micron rating as the original hydraulic filter. This hydraulic filter element offers equal to or better filtration performance based on the original OEM filter specifications.

Hydraulic filter elements are used to remove contamination from a lube oil or hydraulic fluid system. These hydraulic filters provide the highest level of clean fluids to reduce operating costs and prevent failure. Our hydraulic filter cartridges are tough enough to hold their shape under pressure and maintain even pressure differentials to avoid collapsing of the filter element.

The PELF-PM-9-HF-2-PL-005-PES-PA V-1 filter element equivalent is manufactured with the highest quality standards and is guaranteed. We have replaced all major brands of OEM and replacement filters in tens of thousands of applications.

The PELF-PM-9-HF-2-PL-005-PES-PA V-1 filter element replacement has the same dimensions and micron rating as the original hydraulic filter. This hydraulic filter element offers equal to or better filtration performance based on the original OEM filter specifications.

Hydraulic filter elements are used to remove contamination from a lube oil or hydraulic fluid system. These hydraulic filters provide the highest level of clean fluids to reduce operating costs and prevent failure. Our hydraulic filter cartridges are tough enough to hold their shape under pressure and maintain even pressure differentials to avoid collapsing of the filter element.

The PELF-PM-9-HF-2-PL-005-PES-PA V-1 filter element equivalent is manufactured with the highest quality standards and is guaranteed. We have replaced all major brands of OEM and replacement filters in tens of thousands of applications.

Features

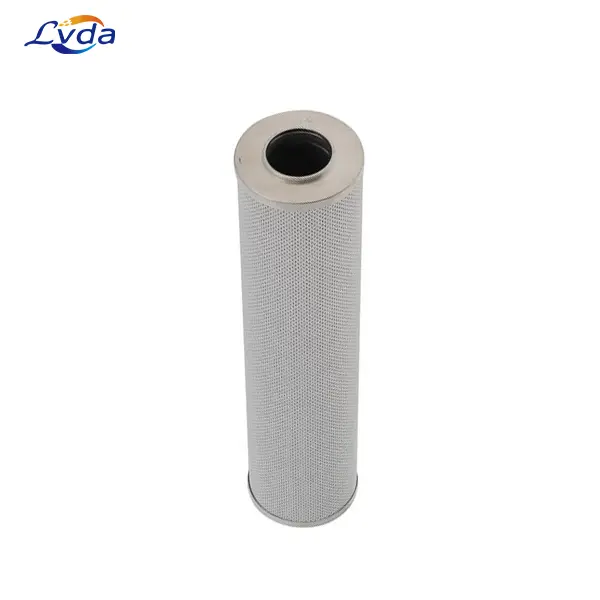

Innovative outer wrap with improved diffusor effect?

Possible use in applications subject to API Standard 614 / ISO 10438

Increased operation safety and longer oil change intervals even when low-conductive oils are employed – through integrated

Cost savings with possible use of smaller filters

Compact design, since the lower pressure drop enables the use of smaller filters

Homogenous flow of the operating fluid

Low pressure drop, due to optimized flow channels

Outer wrap perforations also help to distribute the fluid incidence stresses evenly in the axial and radial directions and thus increase tear resistance.

Outer wrap perforations insure optimized flow onto the filter pleats and help to minimize pressure losses.

Unique pleat geometry – optimizes media area open to flow to calm the flow in areas between pleats reducing

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português