Product Details

Hydraulic filters are placed at various locations throughout a system to catch contaminants created at different points in the process. For ideal filtration, filters would be before and after the pump, in the return lines, off-line and within the reservoir. However, considerations for cost and space impact where designers choose to place filters. There are a few primary locations, which determine the types of hydraulic filters used:

Return lines: These filters are usually low pressure. They collect contaminants from the fluid as it returns to the reservoir and can be positioned along the return line or within the tank. Suction filters: Another example of a low-pressure filter, suction filters are placed at the pump inlet to ensure no contaminants enter the pump.

Pressure lines: These filters are placed after the pump to keep expensive downstream components safe. Pressure filters have a high-pressure capability to remove internal contamination created within the system. This allows for individual component protection. Saving on downtime, maintenance and component repair or replacement costs.

Off-lines: Also called kidney loops, these filters continue working even while the central hydraulic system is not working. An off-line filter draws the fluid from the reservoir and returns it after filtration. These filters are usually easier to maintain because of their placement within reach. Some popular types of off-line filters are the drum topper and portable filter cart, which can service multiple hydraulic systems. Another common kidney loop system is the Filter Panel. It can be mounted directly to the hydraulic system and provide 24/7 filtration if necessary.

Product features

1.Hydraulic filters extend the life of your hydraulic system and its components considerably. Filters maintain an impurity-free fluid by limiting the intake of contaminants and swiftly removing new ones.

2.Hydraulic filters also protect components from failure caused by the build-up of particles between close-fitting parts or lubricated mechanisms. Protection from wear and tear reduces the chance of malfunction and keeps systems safer.

3.An efficient, well-placed filter also saves you money and downtime due to costly replacements or repairs. Ensuring your hydraulic filter suits your equipment’s needs the first time around will prolong its life and allow you to work more efficiently.

Product parameters

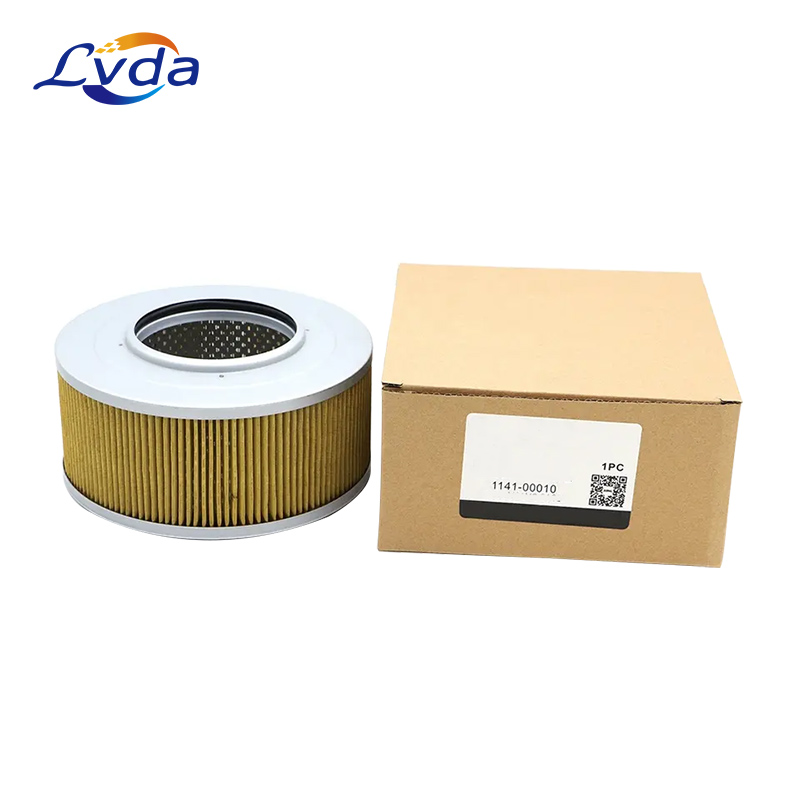

Model | 1141-00010 |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 6000- 8000h |

Certificate | ISO9001 |

Quality | 100% Tested |

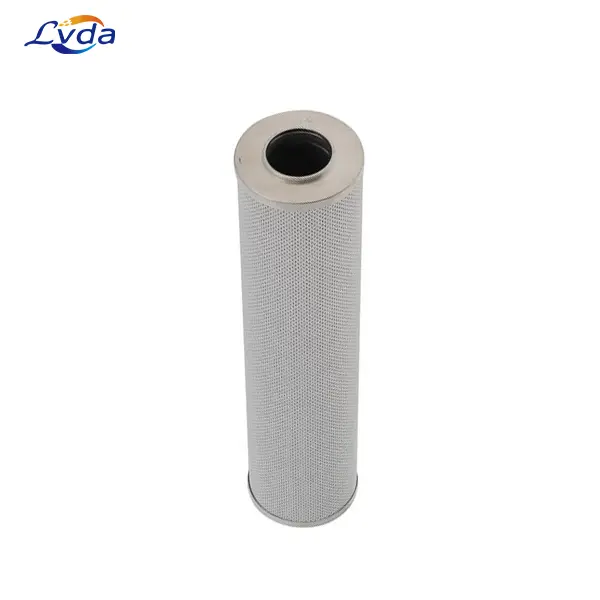

Working temperature: | -10~+100℃ |

Working pressure: | -21~210 bar |

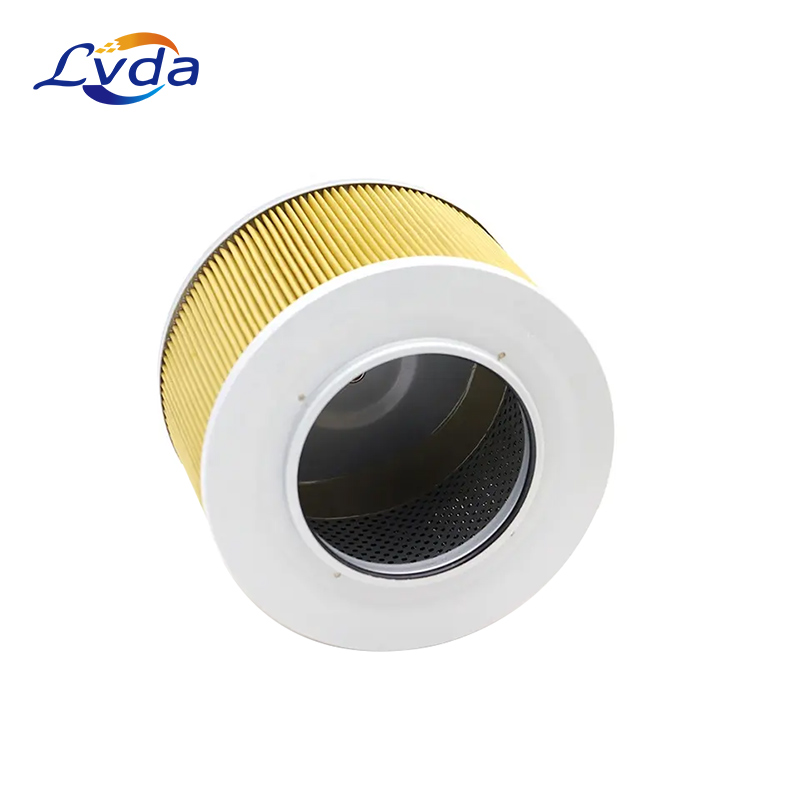

Dimension(L*W*H): | 90*200*100/M10 |

Weight: | 2 kg |

Filtration Grade: | 99.99% |

Structure: | Fixed |

Usage: | Oil-Water Separator |

Type: | Suction Filter |

Mechanical Principle: | Pressure Filtration |

Performance: | Efficient Filtration |

Product application

1.Mainly used for steel mill ,

2.power plant ,

3.mine/resource depot ,

4.paper mill,

5.paper making enterprise power hydraulic station system filtration,

6.petroleum,

7.metallurgy,

8.chemical industry,

9.railway,

10.oil field,

11.oil exploitation,

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português