Product Details

Hydraulic pressure is a device or method that converts mechanical energy of power into fluid pressure energy by a hydraulic pump, operates an actuator such as a hydraulic cylinder or a hydraulic motor, and converts it back into mechanical energy.

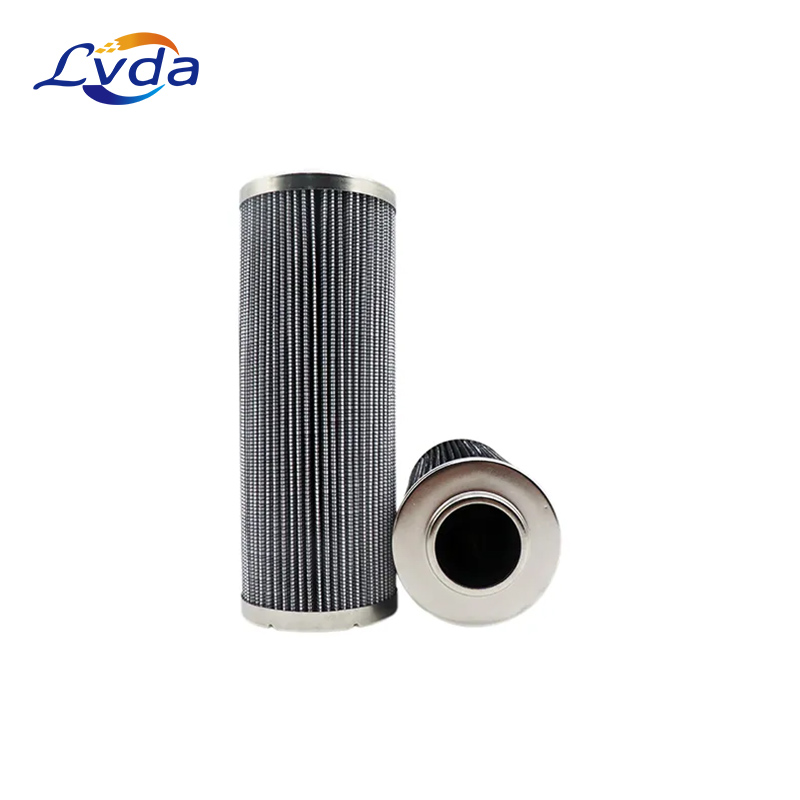

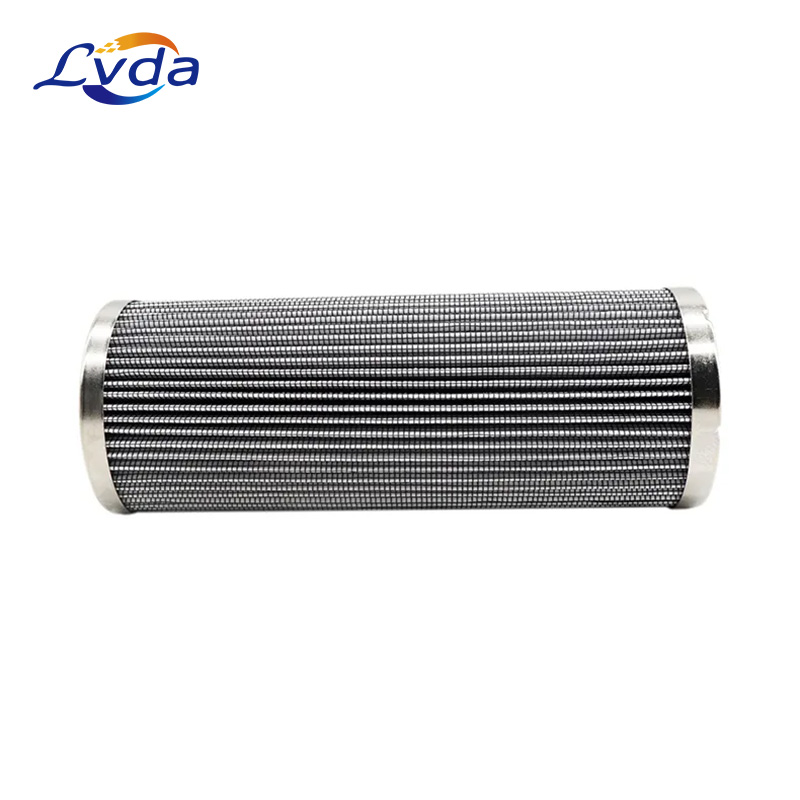

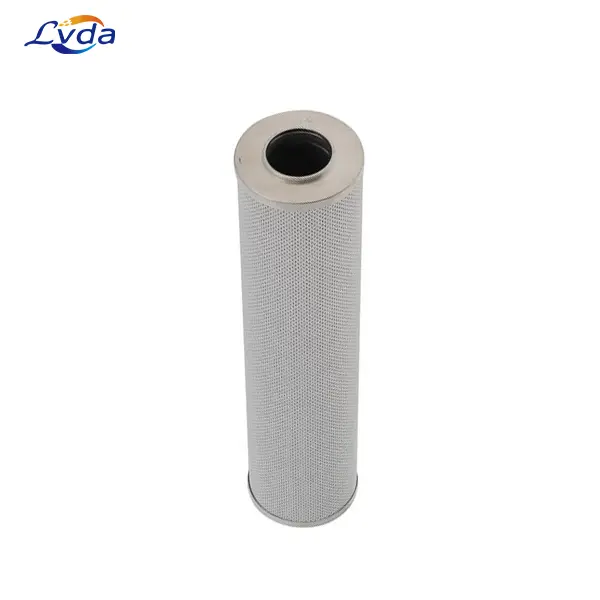

The outside of the filter is a metal can with a sealing gasket that allows it to be tightly held against the engine’s mating surface. The base plate of the can holds the gasket and is perforated with holes around the area just inside the gasket. A central hole is threaded to mate with the oil filter assembly on the engine block. Inside the can is the filter material, most frequently made from synthetic fiber. The engine’s oil pump moves the oil directly to the filter, where it enters from the holes in the perimeter of the base plate. The dirty oil is passed (pushed under pressure) through the filter media and back through the central hole, where it re-enters the engine.

Product features

1.The oil filter helps remove contaminants from your car engine’s oil that can accumulate over time as the oil keeps your engine clean.

2.Include heavy duty components that are built to perform, built to last.

Deliver essential engine protection for maximum cold flow performance.

3.Removes contaminants from the lube oil system

4.Traps abrasive contaminants in the lube oil to keep them from entering the lubrication system

5.Prevents engine damage from dirt and particles in the oil

Product parameters

Model | SH62022 |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 2000 hours |

Certificate | ISO9001:2015 |

Quality | 100% Tested |

Weight: | 1.2 kg |

Filer Material: | HV Filter Paper |

Structure: | Cartridge |

Efficiency: | 99.9% |

MODEL | Spin-om Filter |

Filter Type | hydraulic oil filter |

D1 (mm) | 69.0 mm |

D2 (mm) | 32.5 mm |

H1 (mm) | 190.5 mm |

H2 (mm) | 186.5 mm |

Product application

1. Metallurgy: It is used for filtering the hydraulic system of steel rolling mill and continuous casting machine and filtering various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in oil refining and chemical production, particle removal and filtration of oilfield well water and natural gas.

3. Textile: purification and uniform filtration of polyester melt during wire drawing, protective filtration of air compressor, oil and water removal of compressed gas.

4. Electronics and pharmacy: pretreatment filtration of reverse osmosis water and deionized water, pretreatment filtration of cleaning solution and glucose.

5. Thermal power and nuclear power: purification of lubricating system, speed control system and bypass control system oil of gas turbine and boiler, and purification of feed pump, fan and dust removal system.

6. Mechanical processing equipment: lubrication system and compressed air purification of paper machinery, mining machinery, injection molding machines and large precision machinery, and dust recovery and filtration of tobacco processing equipment and spraying equipment.

7. Railway internal combustion engine and generator: filtering of lubricating oil and engine oil.

8. Automobile engine and construction machinery: air filter, oil filter, fuel filter for internal combustion engine, various hydraulic oil filters, diesel oil filters and water filters for construction machinery, ships and trucks.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português