Product Details

Coalescing filter element is made of a variety of composite materials by special process, which has hydrophilic characteristics. It can not only filter out mechanical impurities in the medium, but also separate emulsified water from the medium through demulsification and coalescence, and coalesce into larger water droplets, which is conducive to further purification of the medium.

The droplets of oil, water and other liquids are captured by the superfine fibers inside the coalescer. These micron sized fibers form a tortuous channel for the air flow, forcing the solid particles and liquid droplets to be captured by the superfine fibers under the action of three filtering mechanisms of inertial collision, diffusion interception and direct interception. The liquid surface tension makes the small droplets coalesce into larger droplets, and the large droplets settle to the bottom of the container due to gravity.

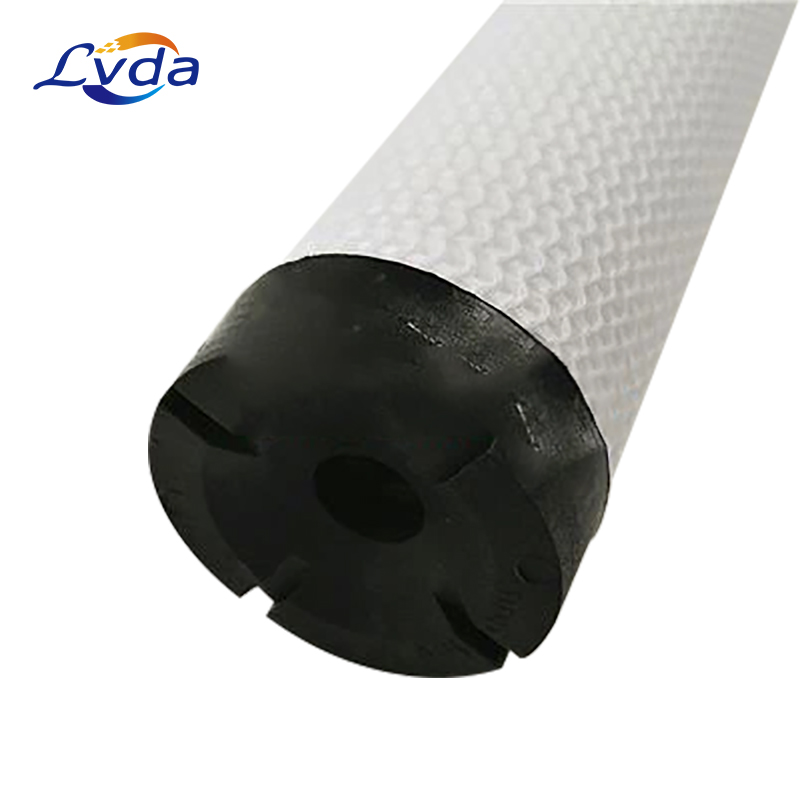

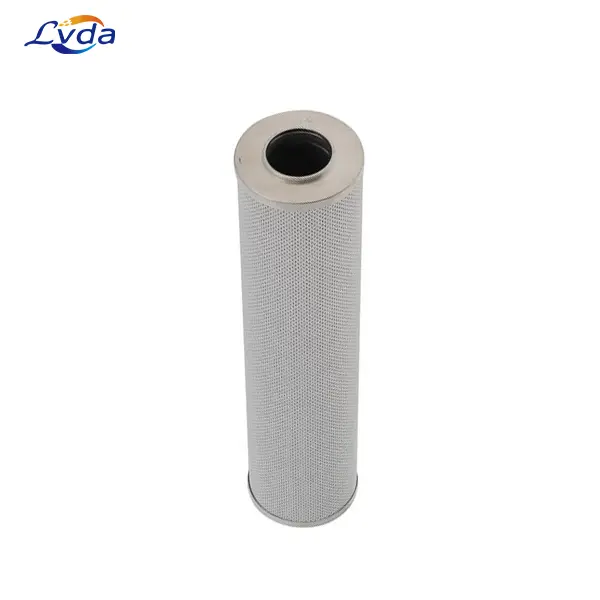

The glass fiber coalescence filter element is made of high-density gradient glass fiber. It is designed as a monolithic tube structure to reduce damage and leakage. The surface of the filter element is treated with water and oil drainage to meet the requirements of various accuracy levels.

Polyester fiber coalescence filter element is usually made of polyester fiber synthetic material, which has good compatibility with various fluids. The filter element is made of multi-layer spiral structure, and each layer uses fibers with different properties. The expected filtering accuracy is achieved by controlling the shape, size, thickness, density and other parameters of each layer of fibers.

The coalescence filter element mainly selects glass fiber or polyester fiber with surface treatment as the coalescence medium. The structure of the filter material is specially designed to make the filter medium have good coalescence performance. The filtering accuracy can reach 0.1 μ m.

Product features

1. Glass fiber coalescing filter element High density gradient glass fiber, highly efficient coalescing of liquid mist and droplets in the air stream, high filtering accuracy.

2. The structure is stable, and there is no medium fiber falling off, which will not pollute the environment and the downstream of the product.

3. Good compatibility with various fluids;

4. Good environmental protection, 100% synthetic material, complete combustion without residue.

Product parameters

Model | CDF 230P |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 6000- 8000h |

Certificate | ISO9001 |

Quality | 100% Tested |

Working temperature: | -10~+100℃ |

Working pressure: | -21~210 bar |

Micron Rating (µm): | 0.5 |

Outside Diameter (inch): | 2 |

Length (inch): | 30.8125 |

Fuel Monitor Collapse Pressure: | 175 psi |

Maximum Operating Temperature: | 71.1 °C, 160 °F |

Flow Rate: | 30Gal/min |

Changeout Pressure Differential: | 25 psi, 1.72 bar |

Product application

1. Aviation fuel, gasoline, kerosene, diesel;

2. LPG, petroleum tar, benzene, toluene, xylene, cumene, polypropylene benzene, etc;

3. Turbine oil and other low viscosity hydraulic oil and lubricating oil;

4. Cycloethane, isopropanol, cyclohexanol, cyclohexanone, etc;

5. Other hydrocarbons

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português