Product Details

The oil filter element is mainly used for filtering oil in the hydraulic system, and is installed in the filter and oil filter in the hydraulic system. In the oil circuit of the hydraulic system, it is used to remove the metal powder and other mechanical impurities worn by various components in the hydraulic system to keep the oil circuit clean, which can prolong the service life of the hydraulic system; The low pressure series filter element is also equipped with a bypass valve. When the filter element is not replaced in time, the bypass valve can automatically open to ensure the normal operation of the system.

The air filter element is a kind of filter, also called air filter cartridge, air filter, style, etc. It is mainly used for air filtration in engineering locomotives, automobiles, agricultural locomotives, laboratories, aseptic operating rooms and various precision operating rooms. The engine will suck in a lot of air during operation. If the air is not filtered, the suspended dust in the air will be sucked into the cylinder, which will accelerate the wear of the piston set and cylinder. Large particles entering between the piston and the cylinder will cause serious "cylinder pulling", which is particularly serious in a dry and sandy working environment. The air filter is installed in front of the carburetor or the intake pipe to filter out dust and sand particles in the air and ensure that sufficient and clean air enters the cylinder.

The water filter element filters impurities in the coolant to prevent scale formation and ensure the normal operation of the engine cooling system. Water filter element plays an increasingly important role in engines. The water filter element can filter impurities in the water, protect the cylinder liner of the engine through high-quality filtering medium, prevent scale, stress corrosion, etc., thus extending the service life of the engine and reducing maintenance costs.

Product features

1.High filtration efficiency

2.long performance life

3.Easy to install

4.Product & service innovations.

5.standard and clever design

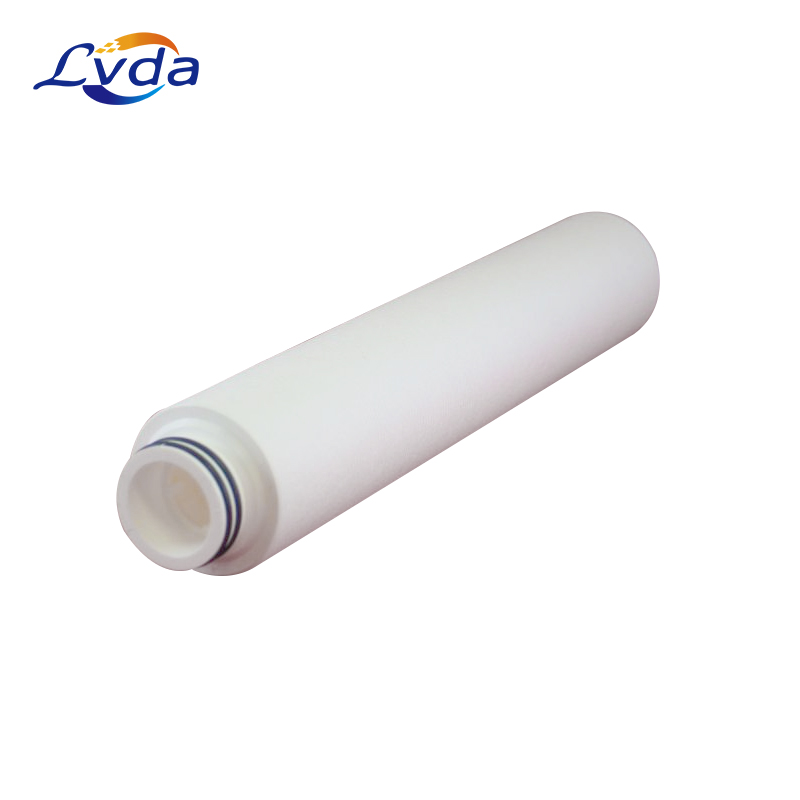

Product parameters

Model: | ME3310FPR13H132 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | ISO9001 |

Quality: | 100% Tested |

Working temperature: | -10~+100℃ |

Working pressure: | -21~210 bar |

Category: | Process Cartridges |

Filter Type: | Thermal Bond-Melt blown |

Length: | 14.25 |

Outer Diameter: | 2.5 |

Filter Type: | Thermal Bond-Melt blown |

Filtration Selectivity Raring: | 40 MICRON |

Maximum Flow: | 8 GPM |

Operating Temperature Range: | MAX 180F |

Initial Differential Pressure: | < 1 PSID @ 5 GPM |

End Caps: | 222/FLAT |

Gasket: | BUNA |

Product application

1.Mainly used for steel mill ,

2.power plant ,

3.mine/resource depot ,

4.paper mill,

5.petroleum,

6.metallurgy,

7.chemical industry,

8.railway,

9.oil field,

10.oil exploitation,

11.pharmaceutical factory aviation,

12.electronics,

13.power,

14.pharmaceutical,

15.environmental protection,

16.atomic energy,

17.nuclear industry,

18.refractory materials,

19.fire fighting equipment.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português