Product Details

Maintenance method of filter element:

1. Before replacement, drain the original liquid jade oil, check the oil return filter element, oil suction filter element, and pilot filter element to see if there are iron filings, copper filings, or other impurities. If there are some hydraulic component failures, clean the system after troubleshooting.

2. When changing hydraulic oil, all hydraulic oil filter elements (oil return filter element, oil suction filter element, pilot filter element) must be replaced at the same time, otherwise, it is equivalent to no replacement.

3. Identify the hydraulic oil grades. Hydraulic oils of different grades and brands shall not be mixed, which may react and deteriorate to produce flocs. It is recommended to use the excavator oil.

4. Before refueling, the oil suction filter element must be installed first. The nozzle covered by the oil suction filter element directly leads to the main pump. If impurities are introduced, the wear of the main pump will be accelerated, and if it is heavy, the pump will be started.

5. Fill the oil to the standard position. There is usually an oil level gauge on the hydraulic oil tank. Check the level gauge. Pay attention to the parking mode. Generally, all cylinders are retracted, that is, the jib and bucket are fully extended and landed.

6. After refueling, pay attention to the air discharge from the main pump. Otherwise, the whole vehicle will not operate temporarily, and the main pump will make abnormal noise (air sonic boom), or the main pump will be damaged. The air exhaust method is to directly loosen the pipe joint at the top of the main pump and directly fill it.

Product features

1. OEM quality standard guaranteed.

2.Product upgrading and expansion of species.

3.Good quality with competitive prices.

4.Flexible and convenient logistic service.

5.Excellent and high-quality control.

6.Long lasting working life time.

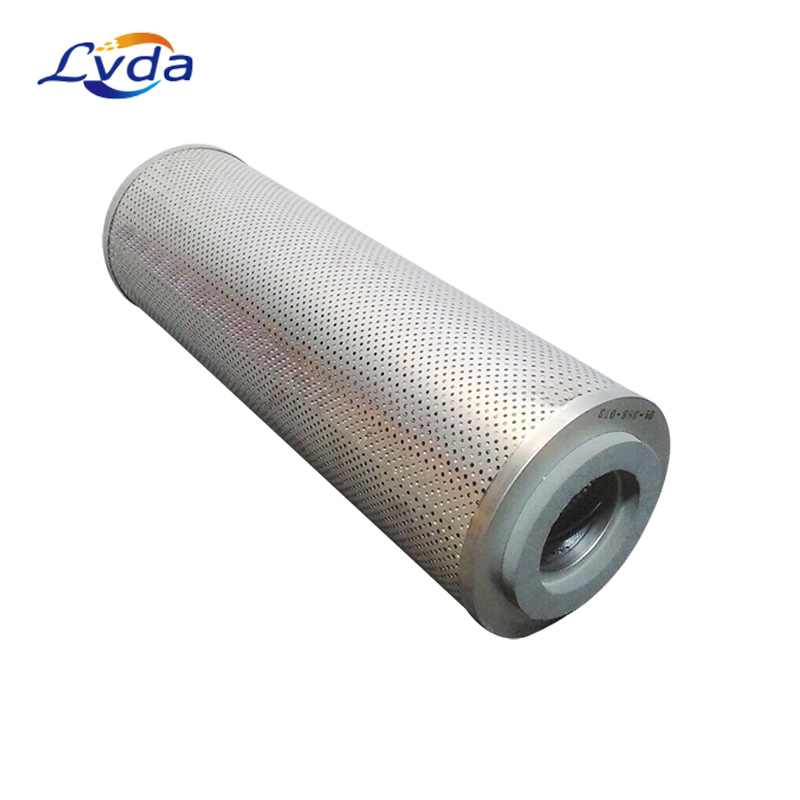

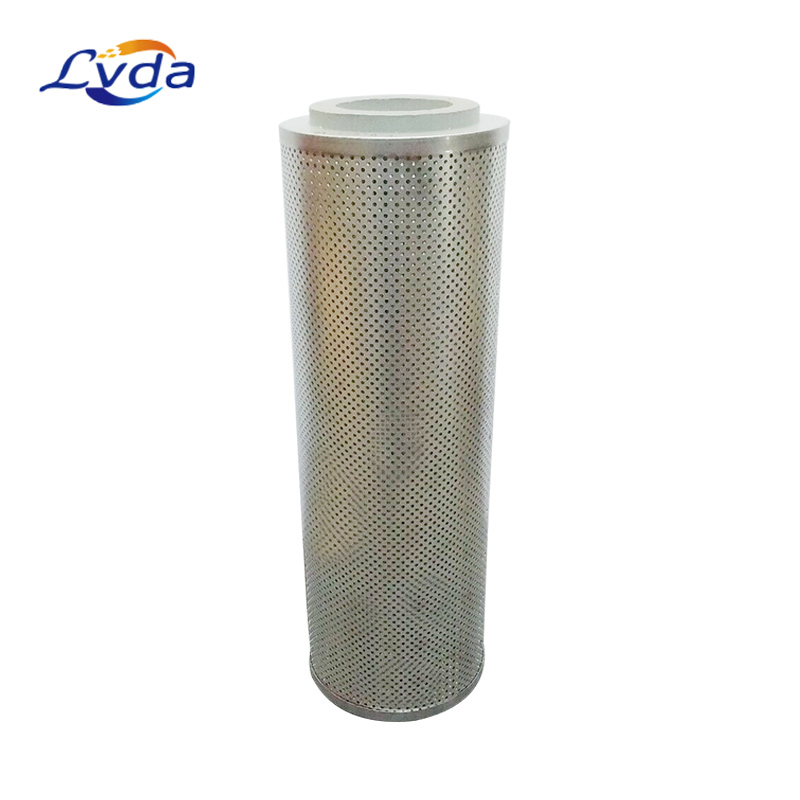

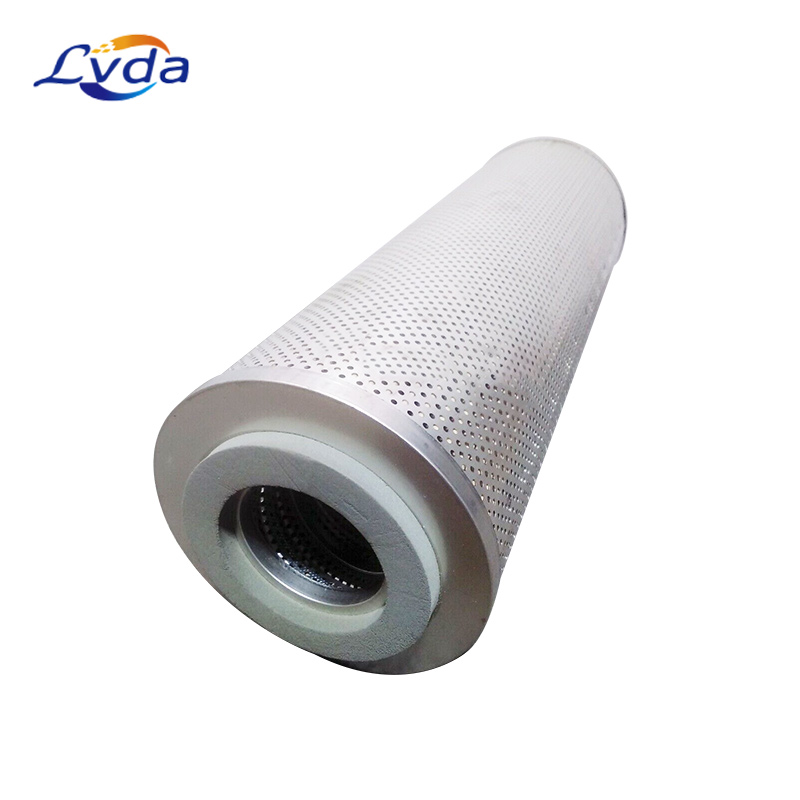

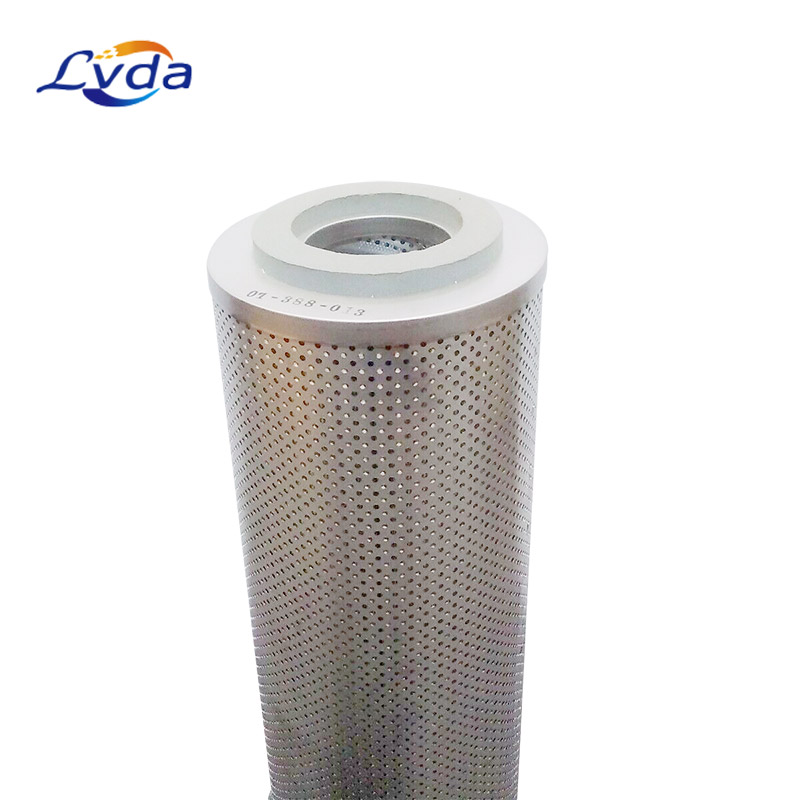

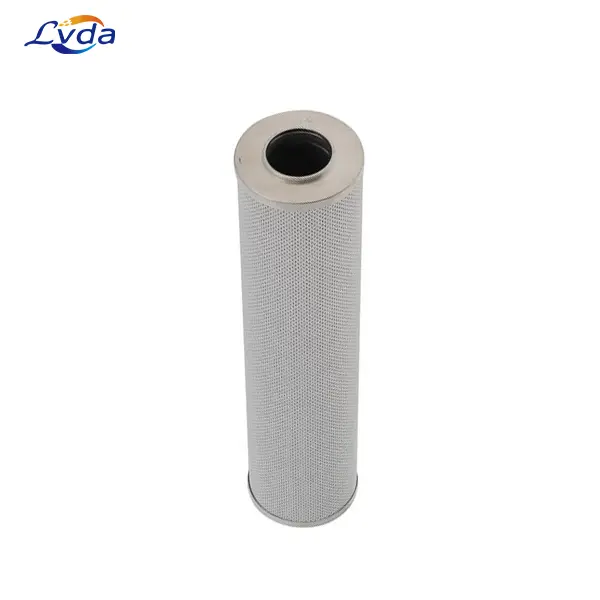

Product parameters

Model | 01-388-013 |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 2000- 4000h |

Certificate | ISO9001:2008 |

Quality | 100% Tested |

Precision: | 25 micron |

Material: | filter paper |

Weight: | 19.40 lbs |

Maximum Temperature: | 225 F |

Direction of Flow: | OUTSIDE->IN |

Recommended Changeout Differential Pressure: | 20 PSID |

Outer Diameter, Top: | 6.00" (152.40 MM) |

Outer Diameter, Bottom: | 6.00" (152.40 MM) |

Inner Diameter, Top: | 2.63" (66.80 MM) |

Inner Diameter, Bottom: | 2.63" (66.80 MM) |

Length: | 18.00" (66.80 MM) |

Thread: | No Thread |

Seal Material: | BUNA-N |

Type of Adhesive: | EPOXY |

Type of Endcap: | PLATED STEEL |

Center Tube: | PLATED STEEL |

Type of Media: | PAPER |

Filter Area: | 32 SQ.FT. |

Plating: | ELECTROTIN PLATED |

Outer Jacket: | YES - METAL |

Configuration: | DOUBLE OPEN END |

Product application

1, Hydraulic Engineering Systems Industry;

2, Mining and Metallurgical Equipment Industry;

3, Construction, engineering machinery industry;

4, Machine Tool Industry;

5, Agricultural machinery industry;

6, Plastic machinery industry;

7, Petrochemical industry;

8, Ship and marine engineering equipment industry.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português