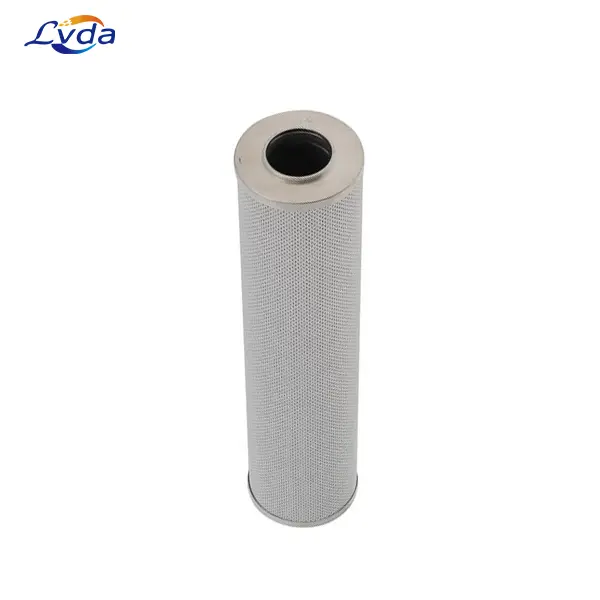

Product Details

A hydraulic filter is a component used by hydraulic systems to continuously remove contaminants in the hydraulic oil. This process will purify the hydraulic fluid and protect the system from damages created by the particle contents. Hydraulic filter type for a specific application is selected on the basis of its fluid compatibility, application type pressure drop, operating pressure, size, design, etc…

Every hydraulic system will contain some basic hydraulic filter components like filter head, filter bowl, element and bypass valve. Filter head can be of different size inlet/outlet connections. It allows the contaminated fluid to enter and filtered fluid to exit. The filter bowl is located inside the housing that threads with the filter head and it will protect the element by controlling the fluid flow. The element is considered as the most important component that holds the filter media for removing contaminants. The bypass valve can be a relief valve that opens for the direct flow of hydraulic fluid if the filter contains increased dirt deposits.

Hydraulic filters are located at different parts of the hydraulic system, that prevents the entry of contaminant particles into the system. Air filters, suction filters, pressure filters, return filters, and off-line filters are some of the commonly found hydraulic filters.

The basic working principle of hydraulic filters is similar except for off-line filter. In general, the working fluid in the hydraulic system will enter through the inlet of the hydraulic filter and after filtration, it is pumped out through the outlet port of the hydraulic system. As a result of continuous operation, the deposits of dirt particles at the inlet of filtration element will generate a pressure differential at the inlet and outlet of the filter. When the bypass relief valve senses this pressure difference, the valve will open and pass the fluid directly from inlet to outlet port by sending an indication to replace/clean the filter.

Product features

1.Eliminate the presence of foreign particles in hydraulic fluid

2.Protect the hydraulic system from the dangers of particle contaminants

3.Improves the overall efficiency and productivity

4.Compatible with most of the hydraulic system

5.Low cost for maintenance

6.Improves the service life of hydraulic system

Product parameters

Model: | 6W2606800 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | ISO9001:2015 |

Quality: | 100% Tested |

Diameter: | 117*208*109 |

weight | 350 g |

Product application

1.Automotive

2.Electronics

3.Food & Beverages

4.Chemical

5.Petrochemical

6.Plastics

7.Paint

8.General Industrial application

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português