Product Details

Filter precision μm

HC: 3

HT:1

HA:0.01

HH: activated carbon 0.01

HC level is suitable for filtering liquids and 3 micron agglomerates (5ppmw/w residual oil content)

Two perforated stainless steel tubes with 10 micron mechanical separation Deep fiber media filters 3 micron solid and liquid particles.

HT rating Suitable for liquid water and oil filtration: can filter solid particles as small as 1 micron (1.0ppmw/w residual oil powder content).

HH grade is suitable for filtering oil vapor and hydrocarbon vapor that can usually be absorbed by carbon; can filter solid particles as small as 0.01 micron (0.003ppmw/w residual oil content).

HA grade is suitable for coalescing fine water vapor and oil mist, and can filter solid particles as small as 0.01 μ m (0.01 ppmw/w residual oil content)

Level 1 multi-layer fiber media and media filter screen to filter out larger particles, and pre filter the air before it enters level 2 filtration

Level 2 multilayer adhesive fiber medium, filtering out fine agglomerates

The inner and outer filter elements are corrosion resistant, and the outer coated film is closed foam sleeve.

Test Standards:

ISO 2941 Verification of collapse/burst resistance

ISO 2942 Verification of fabrication integrity and determination of the first bubble point

ISO 2943 Verification of material compatibility with fluids

ISO 3723 Method for end load testing

ISO 3724 Verification of flow fatigue characteristics

ISO 3968 Evaluation of pressure drop versus flow characteristics

ISO 16889 Multi-Pass method for evaluating filtration performance

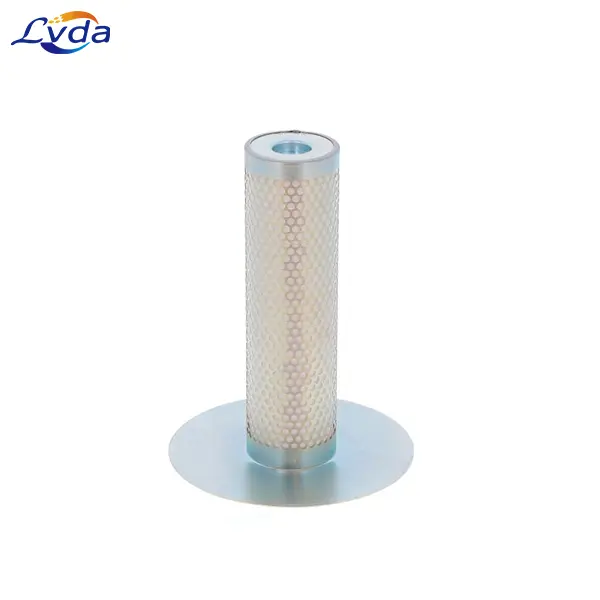

Product features

1. Air permeability of precision filter element:

The filter element is made of American strong hydrophobic and oil repellent fiber filter material, and at the same time, it uses a framework with good permeability and high strength to reduce the resistance caused by passing.

2. High efficiency of precision filter element:

The filter element is made of German fine perforated sponge, which can effectively prevent oil and water from being carried away by high-speed airflow, so that small oil drops passing by can gather at the lower end of the filter element sponge and be discharged to the bottom of the filter container.

3. Tightness of precision filter element:

A reliable sealing ring is used at the joint of the filter element and the filter housing to ensure that the air flow is not short circuited and prevent impurities from directly entering the downstream without passing through the filter element.

4. Corrosion resistance of precision filter element:

The filter element is made of anti-corrosion reinforced nylon end cap and anti-corrosion filter element framework, which can be used in severe working conditions.

Product parameters

Model: | SAGL-40HA |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | TS16949/ISO9001:2015 |

Quality: | 100% Tested |

Max Differential pressure Max. | 5 bar |

Efficiency | 99.99998% |

End Caps | Stainless steel SS304 end caps |

Degree of filtration | 0,2µ |

Material(s) | Borosilicate |

Connection | Silicone (others available) |

Working Temperature | -20°C to 200°C |

Product application

1.Pharmacy,

2.Chemical Industry,

3.Food,

4.Drinks,

5.Environment Protection

6.Spin,

7.Cosmetic Production,

8.Pneumatic Conveying,

9.Pneumatic Tools,

10.Aseptic Packaging

11.Plastic,

12.Chemical Engineering,

13.Metalware,

14.Mechanical Electromechanical,

15.Electronics,

16.Metallurgy

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português