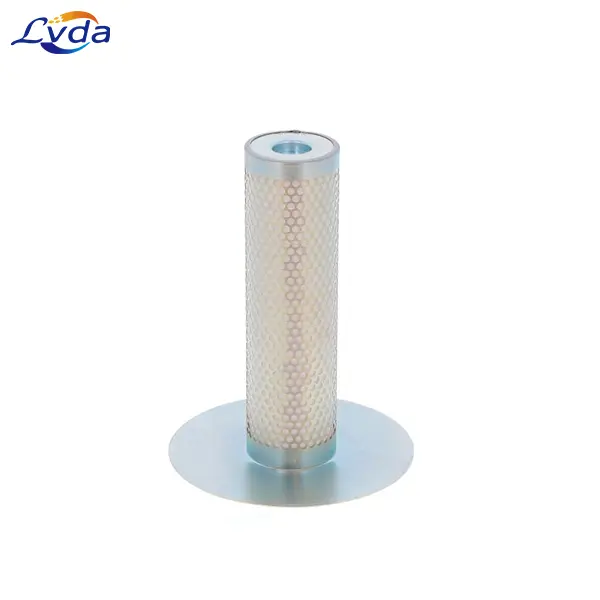

Product Details

The filter design combines high performance, greater efficiency, ease of use, flexibility and safety.

High performance — the flow-optimized filter design, paired with innovative filtration technology, reduces pressure loss by 50% compared to conventional filters.

Safety — the unique bayonet lock ensures that the filter cannot be opened under pressure for increased safety.

Energy savings — you will find that greater energy savings are achieved through timely filter element replacement. Element change out is determined by the Economizer that continuously measures the differential pressure. An integrated microprocessor evaluates the measured data and compares the higher energy costs caused by pressure loss with the costs of a new filter element.

Economizer: Microprocessor monitoring and control indicating the most economical time to change the filter element.

Donaldson DF filters are ideal for filtration of compressed air and other gases in a wide range of applications. The “total filter” design concept behind these filters incorporates the following characteristics: • High performance • Ease of use • High efficiency • Flexibility • Compact size • Safety You will find that greater energy savings are achieved through timely filter element replacement. Element change out is determined by the Economizer that continuously measures the differential pressure. An integrated microprocessor evaluates the measured data and compares the higher energy costs caused by pressure loss with the costs of a new filter element.

Product features

1.Multiple housing sizes, element types and accessories — Allows for unique and specialized solutions for each application

2.Optimized flow design — Reduced pressure drop by 50% - minimum pressure loss means lower energy consumption compared to conventional filters

3.Performance data is validated according to ISO 12500-1 (oil aerosols), 12500-2 (oil vapors) and 12500-3 (particles) — Reliable filtration of compressed air according to ISO 8573-1:2010

4.Filter element can be removed together with filter bowl — Minimizes space needed for filtration installation and servicing

5.Code clip inside the filter bowl can be changed for multiple flow directions through the element — Dual use housings can be used either as a coalescing filter (inside to outside flow) or a particulate filter (outside to inside flow)

6.Bayonet filter bowl lock — Filter cannot be opened under pressure - increased safety

7.Integrated differential pressure indicator — Allows user to replace filter element at the proper interval

8.Immersion-coated housing — Long-term protection against corrosion

Product parameters

MATERIALS |

Filter Housing | Aluminum die cast |

Differential Pressure | DF Standard: Econometer

DF SuperPlus: Economizer |

Float Drain | DF Standard: polymer/aluminum mold cast

(Note: DF1100 MK comes with UFM-P drain valve)

DF SuperPlus: Aluminum, glass fiber reinforced polymer |

Housing Bowl Gasket | Buna |

Model | Capacity1 | Connection

(FNPT) | Element | Dimensions | Weight |

Standard | SuperPlus |

Height A | Width I | Height A | Width J | Standard2 | SuperPlus2 |

m3 /hr | scfm | mm | in | Size | Qty | mm | in | mm | in | mm | in | mm | in | kg | lbs | kg | lbs |

DF 0210 | 209 | 123 | 19 | 3/4" | 0210 | 1 | 368 | 14.5 | 152 | 6 | 533 | 21 | 152 | 6 | 2.3 | 5 | 2.7 | 6 |

Part | DF 0210 ZU SUPERPLUS |

Model | DF |

Housing Size | 210 |

Element Size | Size 0210 |

Element Type | DF |

Connection Type | 3/4 FNPT |

Flow Rate Nominal (Air) | 210 m³/h |

Differential Pressure Gauge | Economizer |

Drain Type | UFM-D |

Maximum Operating Pressure | 16 bar (232 psi) |

Maximum Operating Temperature | 65 °C (149 °F) |

Minimum Operating Temperature | 1 °C (34 °F) |

Filter Housing Material | Aluminum |

Housing Gasket Material | Perbunan |

Length | 140 mm (5.51 inch) |

Width | 139 mm (5.47 inch) |

Height | 535 mm (21.06 inch) |

Weight | 3.1 kg (6.83 lb) |

Drain Connection | G 1/2 |

PED 2014 68 EU | Yes |

EAC | Yes |

Product application

1. Construction machinery industry: excavator, loader, roller, rotary drilling rig, paver

2. Power industry: generator sets, mobile power stations

3. Petrochemical industry: fuel dispensers, oil tankers, mobile fuel tankers

4. Mechanical processing equipment: various mechanical hydraulic system filters such as machining center, lathe, milling machine, bending machine, etc

5. Agricultural machinery: harvester, tractor, lawn mower

6. Transport vehicles: heavy trucks, mixer trucks, buses, sprinklers

7. Ships

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português