Product Details

LVDA Filtration stocks the following OMI filter elements, our elements offer a cost-effective alternative to the OEM product without compromising the filter performance or air quality. We recommend regular filter maintenance to ensure that your compressed air system is running effectively and efficiently – annual element replacement is the industry standard and our recommendation.

The following are the OMI Filter grades:

PF General Pre-Filter - 1 micron

HF Oil Removal - 0.01 micron

CF Activated Carbon

Please be advised, we use the manufacturers part number as our product code for referencing. We do not supply genuine OMI elements.

Product features

1.Good as original parts from factory.

2. Reliable quality with lower price, because we have the first hand source;

3.Covering a wide range, especially in OMI parts, larger stock, and shorter delivery time;

4. we can easily and quickly find the right part for you.

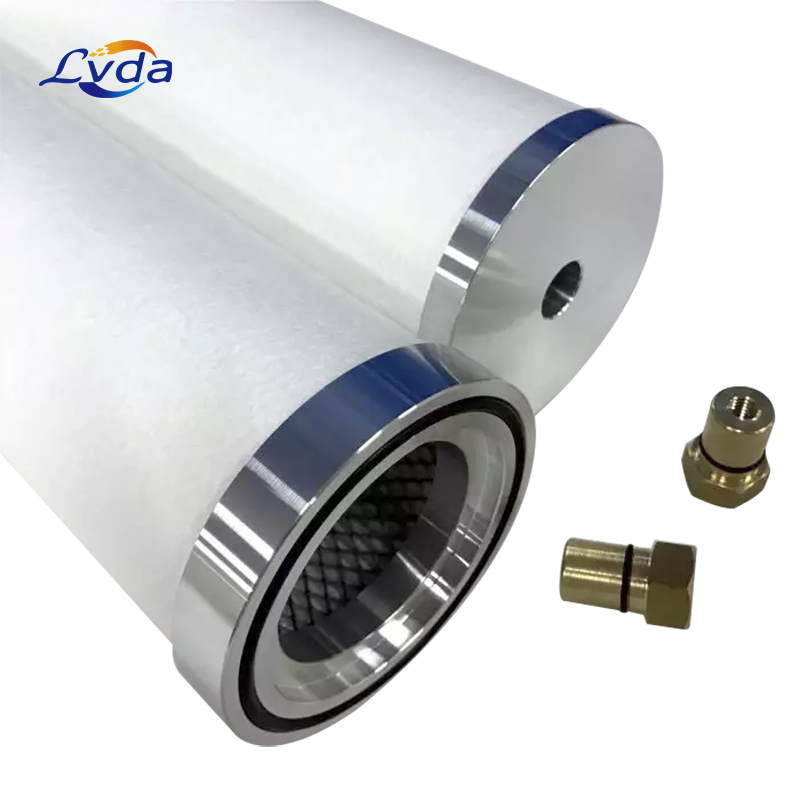

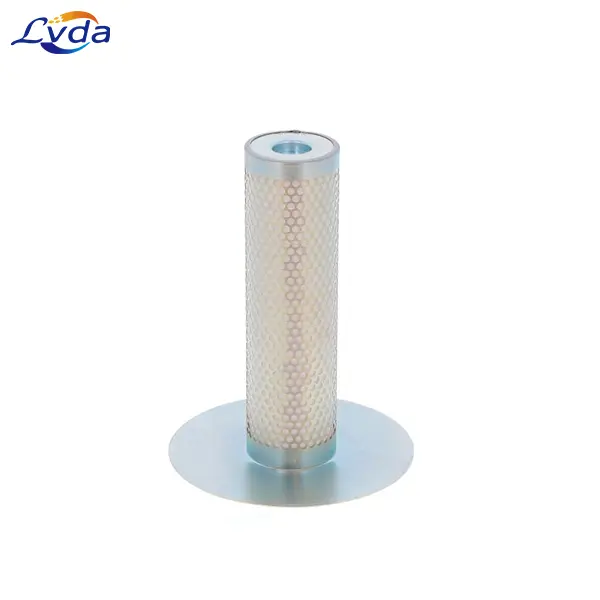

Product parameters

Filter degree according to DIN ISO 8573-1 S | 0.01µm (fine filter)

Features: Class 1 oil: Class 1 |

|

Outside diameter | 60mm |

Height | 144mm |

Material | borosilicate microfiber |

Material type | folded |

End cap | plastic |

Support carrier | stainless steel 1,4301 |

Adhesive type | PU |

Operating temperature | up to 65 ° C |

Print difference dry | 80mbar |

Print difference wet | 190mbar |

Oil separators | 0.01mg/m³ |

Maintenance interval | once a year or from the pressure difference of> 350mbar |

OMEGA AIR Model: | 0036 HF/S |

Company: | Omi |

End cap material: | Plastic |

Diameter: | 60.00 mm |

Height: | 144.00 mm |

Differential pressure dry: | 80 mbar |

Differential pressure wet: | 190 mbar |

Operating temperature Min.: | 1,5 °C |

Operating temperature Max.: | 65 °C |

Flow direction: | Inside to outside |

Grade: | S |

Solid class: | 1 |

Oil class: | 1 |

Particle retention: | 0.01 µm |

Particle retention rate ISO: | 0.99998 |

Residual oil content: | 0.01 mg/m³ |

Product application

1. Metallurgy: It is used for filtering the hydraulic system of steel rolling mill and continuous casting machine and filtering various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in oil refining and chemical production, oilfield injection Particle removal and filtration of well water and natural gas.

3. Textile: purification and uniform filtration of polyester melt during wire drawing, protective filtration of air compressor,Oil and water removal of compressed gas.

4. Electronics and pharmacy: pretreatment and filtration of reverse osmosis water and deionized water, and pretreatment of cleaning solution and glucose

Process filtering.

5. Thermal power and nuclear power: lubrication system, speed control system and bypass control system of gas turbine and boiler Purification of oil, water supply pump, fan and dust removal system.

6. Mechanical processing equipment: lubrication system of paper machinery, mining machinery, injection molding machines and large precision machinery

Purification of compressed air, dust recovery and filtration of tobacco processing equipment and spraying equipment.

7. Railway internal combustion engine and generator: filtering of lubricating oil and engine oil.

8. Automobile engine and engineering machinery: air filter, engine oil filter, fuel filter and engineering machine for internal combustion engine Various hydraulic oil filters, diesel filters and water filters for machinery, ships and trucks.

9. Various lifting and handling operations: lifting, loading and other engineering machinery to fire protection, maintenance and handling

Hoisting and closing of cargo winch, windlass, blast furnace, steelmaking equipment, ship lock and ship door Set, lift orchestra pit and lift stage of theater, various automatic conveying lines, etc.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português