Product Details

1. During installation, whether flange, rubber pipe or direct connection is adopted between the air filter and the engine intake pipe, it must be tight and reliable to prevent air leakage. Rubber gaskets must be installed on both ends of the filter element; The wing nut fixing the air filter cover cannot be tightened too tightly to avoid damaging the paper filter element.

2. During maintenance, the paper filter element must not be cleaned in oil, otherwise, the paper filter element will become invalid, which may also cause flying accidents. During maintenance, only use vibration method, soft brush brushing method (brush along its folds) or compressed air back blowing method to remove the dust and dirt attached to the surface of the paper filter element. For the coarse filter part, the dust at the dust collection part, blade and cyclone tube shall be removed in time. Even if the paper filter element can be carefully maintained every time, it will not completely restore its original performance, and its air inlet resistance will increase. Therefore, when the paper filter element needs the fourth maintenance, it should be replaced with a new filter element. If the paper filter element is cracked, perforated or the filter paper is unglued from the end cover, it should be replaced immediately.

3. When using, it is necessary to prevent the core air filter from being wetted by rain, because once the paper core absorbs a lot of water, it will greatly increase the air inlet resistance and shorten the mission. In addition, the paper core air filter cannot contact with oil and fire.

4. Some vehicle engines are equipped with whirlwind air filters. The plastic cover at the end of the paper filter element is a deflector. The blades on the cover make the air rotate. 80% of the dust is separated by centrifugal force and collected in the dust collecting pocket. The dust reaching the paper filter element is 20% of the dust inhaled. The total filtering efficiency is about 99.7%. Therefore, when maintaining the cyclone air filter, be careful not to miss the installation of the nutrient guide cover on the filter element.

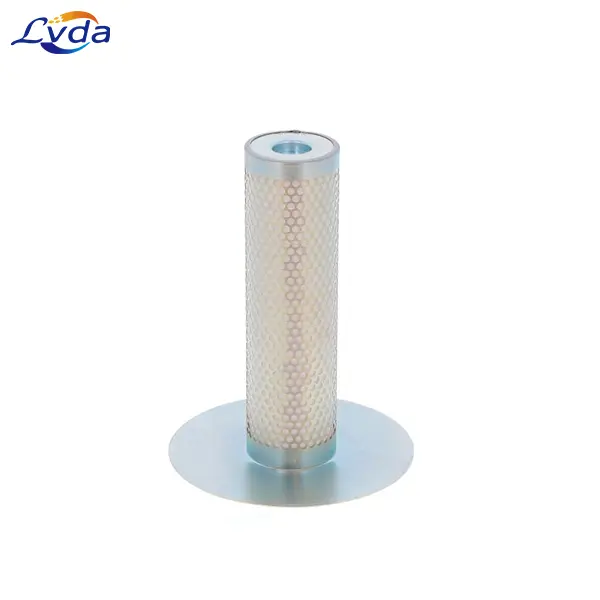

Product features

1.Strong, pliable gasket is compressed against the air cleaner housing to create a tight seal.

2. High-efficiency cellulose media performs across a wide range of heavy-duty engine applications.

3. Corrosion resistant, coated steel liners support media during operation and help maximize airflow.

4. Pleatloc™ feature ensures uniform pleat spacing and prevents media from bunching to promote longer service life.

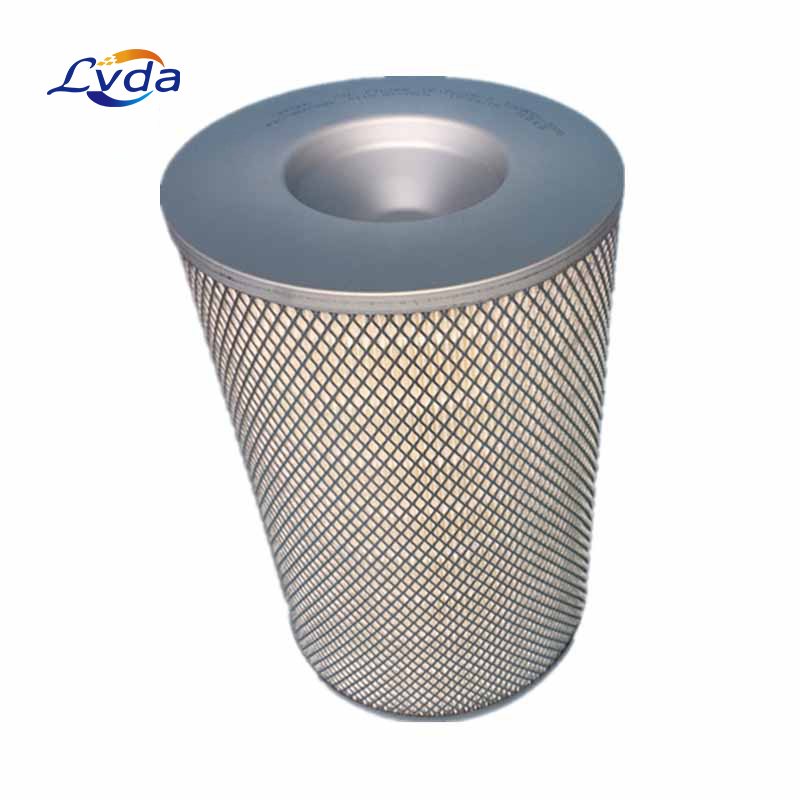

Product parameters

| Outer Diameter | 9.62 inch (244.3 mm) |

| Inner Diameter | 5.26 inch (133.7 mm) |

| Length | 0.65 inch (16.51 mm) |

| Overall Length | 15.50 inch (393.7 mm) |

| Bolt Hole Diameter | 0.65 inch (16.51 mm) |

| Efficiency | 99.9 |

| Efficiency Test Std | ISO 5011 |

| Type | Primary |

| Style | Round |

| Media Type | Cellulose |

| Packaged Length | 10.4 IN |

| Packaged Width | 10.2 IN |

| Packaged Height | 16.5 IN |

| Packaged Weight | 5.955 LB |

| Packaged Volume | 1.0129

FT3 |

Product application

1.Power plant

2.Steel mill

3.Subway engineering

4.Chemical factory

5.Ship

6.Paper mill

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português