Product Details

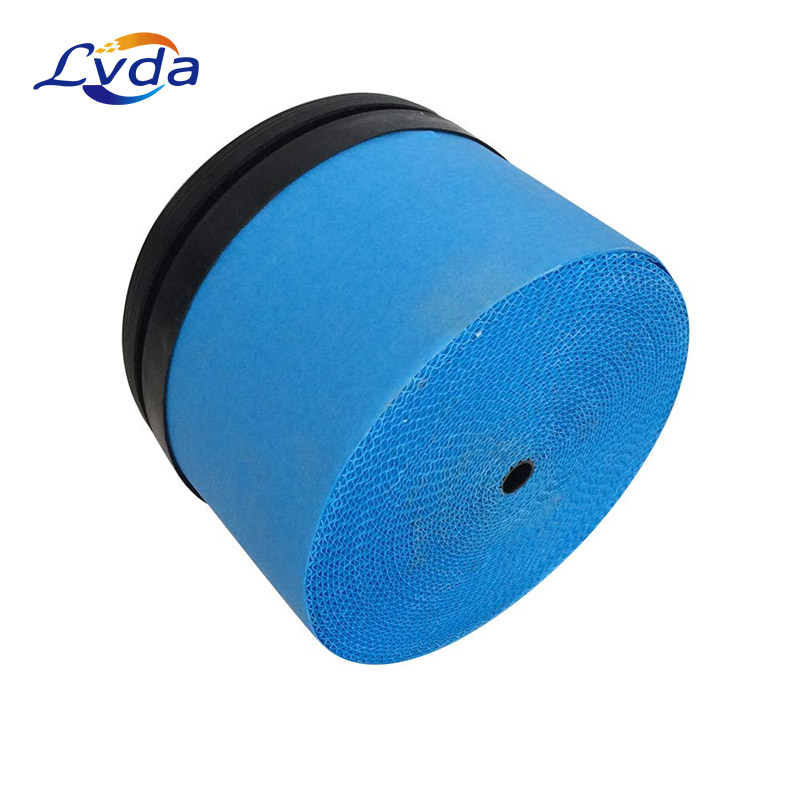

Honeycomb filter element structure

The honeycomb filter element is neither a filter bag nor a filter cartridge in structure. This structure was first applied to the treatment of automobile exhaust particulates. Due to the narrow space inside the automobile, only compact and efficient filter elements can be used for treatment. The honeycomb filter element is designed to solve this problem. At present, the filtering technology has been transferred from the application of automobile exhaust to industrial dust treatment, and the ash removal system is configured to enable the whole system to operate continuously and reliably.

Honeycomb filter element is composed of several layers, each layer is evenly arranged with triangle strip filter tank, and each filter tank is bent by sheet filter material

One side of the filter is closed, and the other side is open and arranged in parallel. The dusty gas is driven by the pressure difference. After entering the triangle strip filter tank from the open end, the air flow filters the three sides of the filter material because the end is closed. The dust is trapped inside the filter tank, and the clean air is discharged from the open end of the adjacent triangle filter tank to complete the dust purification process.

At home and abroad, honeycomb dust collectors have been successfully put into use in many industries, including: welding dust treatment, plasma cutting dust treatment, mining industry dust treatment, metal processing dust treatment, tobacco industry dust treatment, wood processing industry dust treatment, grain industry dust treatment, etc.

Product features

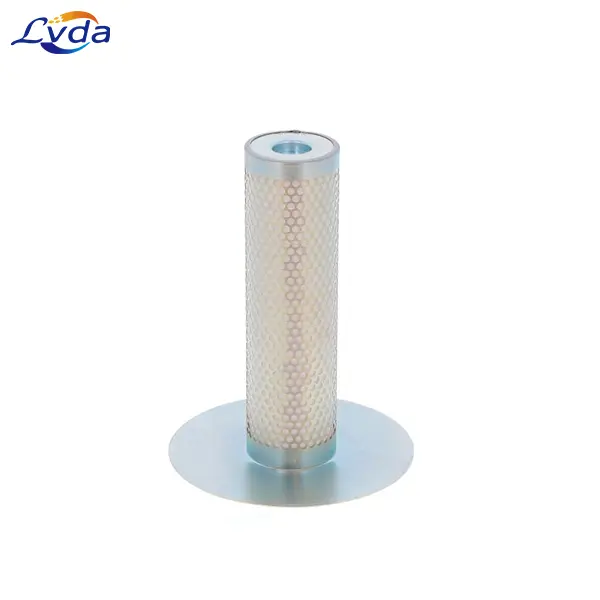

1. The biggest advantage of honeycomb dust remover is to reduce the floor area of the dust remover with its efficient processing capacity. By volume, compared with filter cartridges and bags of the same volume, the air volume handled by the honeycomb filter element is 3 times that of the filter cartridge and 6 times that of the filter bag.

2. The dust remover can be operated stably for a long time to ensure the reliability of the system.

3. Due to the low operating differential pressure of the honeycomb dust remover, the operating power of the fan can be greatly reduced, thus saving the operating cost for users.

Product parameters

Model: | 146397-12 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 1800-2000h |

Certificate: | ISO9001 |

Quality: | 100% Tested |

Weight: | 8.58 LBS |

Medium Material: | Fiberglass |

Filtration Grade: | Pre Filter |

Type: | Air Filter |

Color | Blue |

Maximum outer diameter (mm): | 250 |

Full height (mm): | 180 |

Product application

1.Chemical and petrochemical industry

2.Pharmaceutical industry

3.Prefiltration of sterile filters

4.Filling machines

5.Food & beverage industry

6.Packing machines

7.Process industry

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português