Product Details

Air compressor filters, also called air line filters, are used in condensed air lines as a way to stop liquids and solid contaminants from entering air compressors. They stop these contaminants from entering the equipment and causing damage. A cubic foot of compressed air may harbor millions of dirt particles, in addition to significant amounts of oil and water. Depending on the application, the compressed air might even contain lead, mercury or other heavy metals.

Without air compressor filters removing such contaminants, the operation of critical system components, such as cylinders and valves, will be compromised. Air filtration is an essential element of proper compressed air preparation and can also prevent seals from swelling and experiencing premature wear. In addition to reducing downtime, clean compressed air results in lower energy costs.

Air Compressor Filter Usage and Maintenance

Compressed air filtration plays a hugely important role in any compressor installation. Having a high-quality air compressor filter will protect your system from particulates, dirt, dust, solid particles, and oil. Harmful contaminants like these can cause damage to your equipment and downstream machinery, wearing down parts and causing blockages.

Without a filter, contamination can even affect your manufactured product, causing loss of production and inevitably landing you with a hefty bill. Therefore, it is essential that high performing filters are used. Poor quality filters may offer a reduced performance, leading to large pressure drops and increasing your energy bill.

Product features

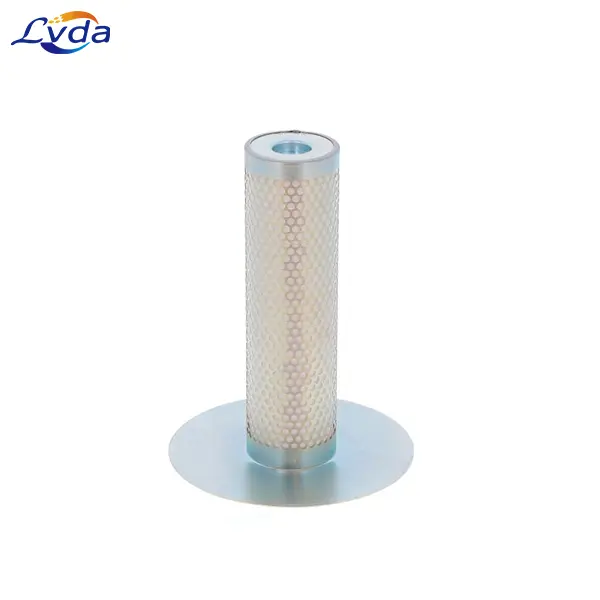

1.Serve as a backup filter in case of primary filter damage or improper installation.

2.Prevent contaminants from entering the clean side of the air intake system during primary filter servicing.

3.Designed to plug rapidly if contamination finds its way past the primary filter, alerting operators about an issue.

4.Recommend that safety filters are replaced with every third primary filter change unless there has been a failure of the primary filter.

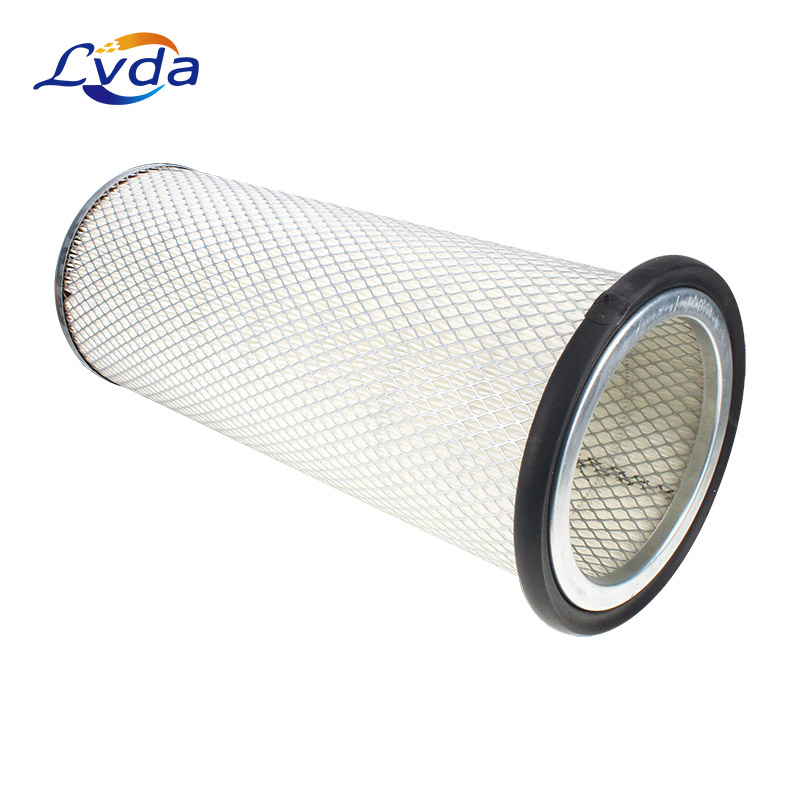

Product parameters

Model: | P119373 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 1800-2000h |

Certificate: | ISO9001 |

Quality: | 100% Tested |

Working pressure: | -21~210 bar |

Outer Diameter | 162.5 mm (6.40 inch) |

Inner Diameter | 134.1 mm (5.28 inch) |

Length | 406.5 mm (16.00 inch) |

Efficiency Test Std | ISO 5011 |

Family | FHG |

Type | Safety |

Style | Round |

Media Type | Safety |

Product application

1.Mainly used for steel mill ,

2.power plant ,

3.mine/resource depot ,

4.paper mill,

5.paper making enterprise power hydraulic station system filtration,

6.petroleum,

7.metallurgy,

8.chemical industry,

9.railway,

10.oil field,

11.oil exploitation,

12.pharmaceutical factory aviation,

13.electronics,

14.power,

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português