Product Details

In the field of fluid filtration, finding a material that can withstand the aggressive nature of corrosive fluids is essential for ensuring the efficiency and longevity of filtration systems. Traditional filter materials often succumb to corrosion, degradation, or loss of efficiency when exposed to these fluids, leading to frequent replacements and increased operational costs. Enter the sintered titanium fiber felt filter material, a groundbreaking innovation that boasts excellent corrosion resistance properties, making it an ideal choice for filtration applications involving corrosive fluids.

Titanium, an element known for its exceptional resistance to corrosion, has long been used in various industries, including aerospace, medical, and chemical processing. The development of sintered titanium fiber felt filter material leverages the inherent properties of titanium to create a filter medium that is unparalleled in its ability to handle corrosive fluids.

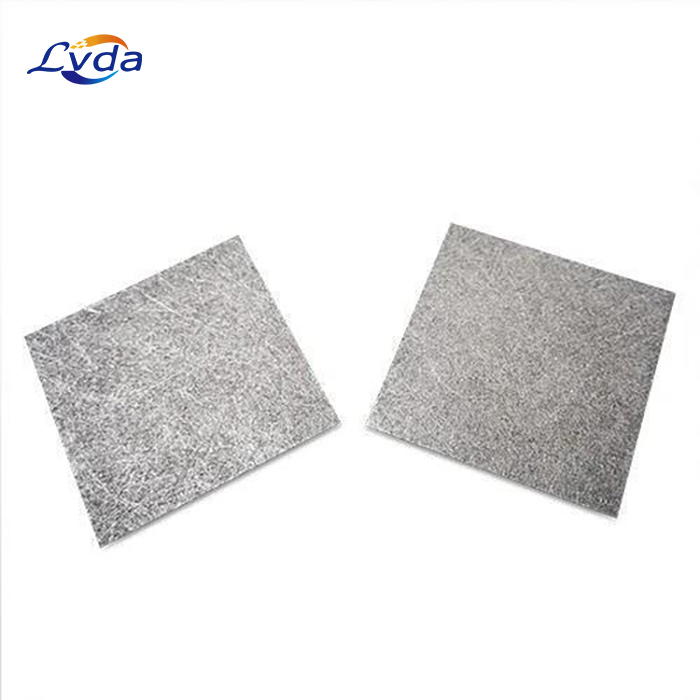

The manufacturing process of sintered titanium fiber felt involves intricately weaving fine titanium fibers into a dense, porous structure. This structure provides a high surface area-to-volume ratio, which enhances the filter's efficiency by allowing for greater contact between the fluid and the filter media. The fibers are then sintered, a process that involves heating the material to a high temperature to bond the fibers together, creating a strong and durable filter material.

One of the key advantages of sintered titanium fiber felt filter material is its excellent corrosion resistance. Titanium's inherent properties, such as its low reactivity and high resistance to acids, bases, and chlorides, make it an ideal choice for filtering corrosive fluids. The material's ability to resist corrosion ensures that the filter remains effective over an extended period, even when exposed to harsh chemical environments. This resistance to corrosion extends not only to common industrial chemicals but also to more aggressive substances, making the sintered titanium fiber felt filter material a versatile solution for various applications.

In addition to its corrosion resistance, the sintered titanium fiber felt filter material offers several other advantages that make it an excellent choice for filtration of corrosive fluids. Its high mechanical strength ensures that the filter material can withstand the pressure and shear forces encountered in filtration processes without degradation. This strength allows for the use of thinner filter layers, reducing pressure drop and improving overall system efficiency.

Furthermore, the material's excellent fatigue resistance prevents fatigue failure, which is common in traditional filter materials when exposed to cyclic loading. This property is particularly crucial in applications where the fluid flow rate fluctuates or where the filter is subject to varying pressures. The sintered titanium fiber felt filter material's ability to maintain its structural integrity under such conditions extends the lifespan of the filter, reducing maintenance requirements, and lowering operational costs.

The high thermal stability of sintered titanium fiber felt filter material ensures its suitability for filtration processes involving high temperatures. The material's ability to maintain its structural and chemical integrity at elevated temperatures makes it an ideal choice for applications in industries such as petrochemical, automotive, and aerospace, where high-temperature corrosive fluid filtration is required.

Another significant advantage of the sintered titanium fiber felt filter material is its biocompatibility. This property makes it an excellent choice for applications in the medical and pharmaceutical industries, where the filtration of sterile fluids is necessary. The material's lack of reactivity with biological substances ensures that the filtered fluid remains contaminant-free, maintaining the integrity of the final product.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português