Product Details

The development of fuel cells, particularly those utilizing hydrogen as a clean energy source, has been a focal point in the pursuit of sustainable and efficient power generation. A key component of these fuel cells is the gas diffusion layer (GDL), which plays a critical role in the management of reactant gases and the removal of product water. The Uniform Pore Size Fuel Cell Gas Diffusion Layer Titanium Sintered Fiber Felt is a specialized material that has been engineered to meet the demanding requirements of fuel cell technology.

The GDL is situated between the electrode (where the electrochemical reactions occur) and the flow field plate (which directs the reactant gases). Its primary functions include:

1. Conductive Pathway for Electrons. The GDL must facilitate the transfer of electrons from the electrode to the external circuit and vice versa.

2. Gas Diffusion. It ensures the even distribution of reactant gases (hydrogen and oxygen) across the surface of the electrode, maximizing the efficiency of the electrochemical reaction.

3. Water Management. The GDL aids in the removal of product water from the electrode surface to prevent flooding and maintain cell performance.

4. Thermal Management. It helps dissipate heat generated during operation, preventing overheating and maintaining a stable operating temperature.

5. Mechanical Support. The GDL provides structural support to the electrode, ensuring good contact with the membrane and flow field plate.

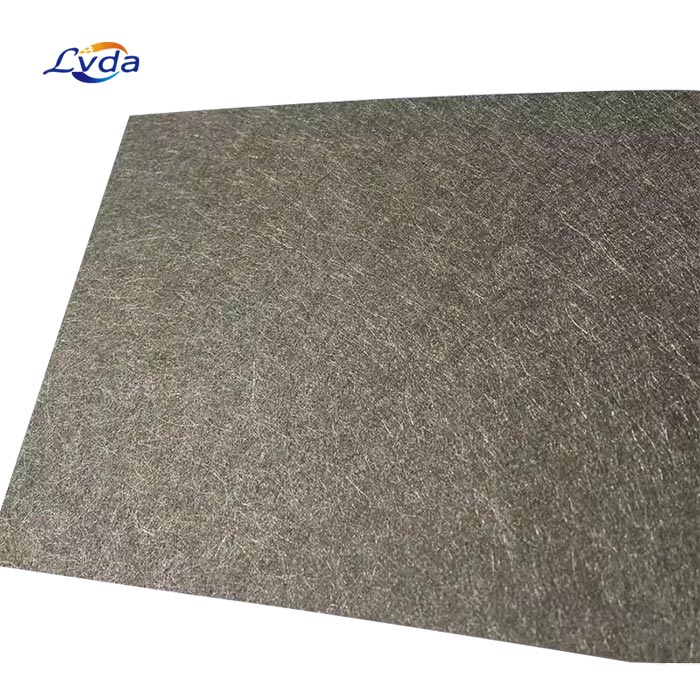

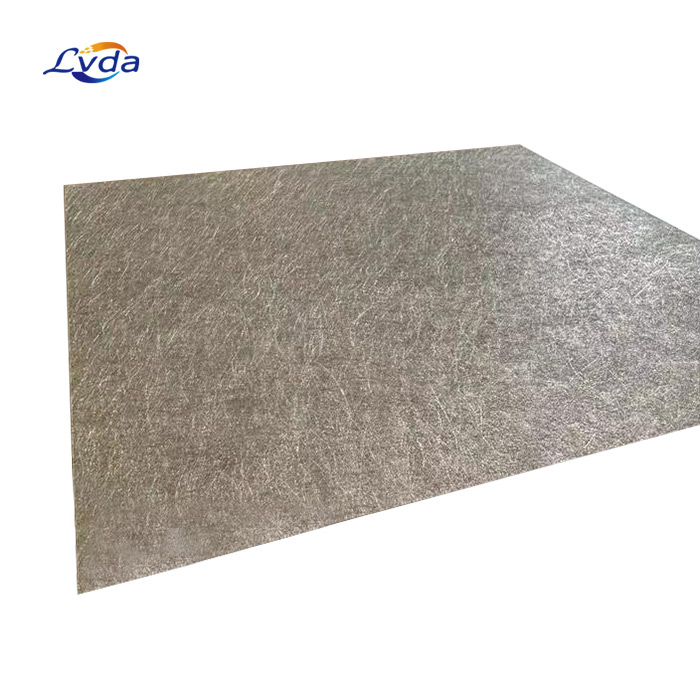

Uniform Pore Size Titanium Sintered Fiber Felt is particularly well-suited for use as a GDL due to its unique characteristics:

1. Uniform Porosity. The felt is engineered to have a consistent pore size, which is crucial for achieving uniform gas diffusion and effective water management. This uniformity ensures that reactants and products are distributed evenly across the electrode, enhancing cell efficiency and reducing the risk of hotspots or dead zones.

2. High Porosity. The high porosity of the titanium fiber felt allows for excellent gas permeability, ensuring that the reactant gases can reach the electrode surface with minimal resistance. This also facilitates the efficient removal of product water vapor.

3. Good Electrical Conductivity. While titanium itself is not as conductive as traditional metals like copper or silver, the sintered fiber structure of the felt provides a network of interconnected fibers that ensure adequate electrical conductivity. In some cases, the titanium felt may be coated with a thin layer of a more conductive material to enhance this property.

4. Corrosion Resistance. Titanium is known for its excellent corrosion resistance, making it suitable for use in the harsh chemical environment of a PEM fuel cell. This means the GDL can maintain its performance over extended periods without degradation.

5. High Temperature Stability. The sintered fiber structure gives the felt good thermal stability, allowing it to withstand the operating temperatures of fuel cells without losing its structural integrity or porosity.

6. Mechanical Durability. The felt is strong and resilient, capable of withstanding the compression forces applied during the assembly of the fuel cell stack. This ensures that the GDL maintains good contact with the electrode and flow field plate throughout the life of the cell.

7. Compatibility with Other Materials. The titanium felt is compatible with the other materials used in fuel cells, such as the polymer electrolyte membrane and the catalyst layers. This compatibility is essential to avoid chemical reactions that could lead to material degradation or performance loss.

In terms of applications, the Uniform Pore Size Fuel Cell Gas Diffusion Layer Titanium Sintered Fiber Felt is widely used in various types of fuel cells, including proton exchange membrane fuel cells (PEMFC), phosphoric acid fuel cells (PAFC), and solid oxide fuel cells (SOFC). Its superior gas diffusion properties, durability, and chemical stability make it an ideal choice for these applications.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português